Peugeot 405 Haynes (petrol). Manual - part 19

4D

Chapter 4 Part D:

Emission control systems

Catalytic converter - general information and precautions . . . . . . . . .3

Emission control system check . . . . . . . . . . . . . . . . . . . .See Chapter 1

Emission control systems - testing and component renewal . . . . . . . .2

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4D•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Contents

1

General information

1 All models have various built-in fuel system

features which help to minimise emissions,

and all models have at least the crankcase

emission-control system described below.

Models with a catalytic converter are also

fitted with the exhaust and evaporative

emission control systems.

2 Most models are able to run on 95 RON

unleaded fuel, but the following early engines

must use 97 RON leaded fuel. However it may

be possible to use unleaded fuel if the ignition

is retarded by 3° - check with your Peugeot

dealer.

a) TU3 (K1A)

b) TU3A (K1G)

c) XU92C (D2D)

d) XU9J2 (D6A)

e) XU9J4 (D6C)

f) XU52C (B2A)

Crankcase emission control

3 To reduce the emission of unburned

hydrocarbons from the crankcase into the

atmosphere, the engine is sealed, and the

blow-by gases and oil vapour are drawn from

the crankcase, through a wire-mesh oil

separator, into the inlet tract, to be burned by

the engine during normal combustion.

4 Under conditions of high manifold

depression (idling, deceleration) the gases will

be sucked positively out of the crankcase.

Under conditions of low manifold depression

(acceleration, full-throttle running) the gases

are forced out of the crankcase by the

(relatively) higher crankcase pressure; if the

engine is worn, the raised crankcase pressure

(due to increased blow-by) will cause some of

the flow to return under all manifold

conditions.

Exhaust emission control

5 To minimise the amount of pollutants which

escape into the atmosphere, some models

are fitted with a catalytic converter in the

exhaust system. On all models where a

catalytic converter is fitted, the system is of

the “closed-loop” type; a lambda (oxygen)

sensor in the exhaust system provides the fuel

injection/ignition system ECU with constant

feedback, enabling the ECU to adjust the

mixture to provide the best possible

conditions for the converter to operate.

6 The lambda sensor has a built-in heating

element, controlled by the ECU through the

lambda sensor relay, to quickly bring the

sensor’s tip to an efficient operating

temperature. The sensor’s tip is sensitive to

oxygen, and sends the ECU a varying voltage

depending on the amount of oxygen in the

exhaust gases. If the inlet air/fuel mixture is

too rich, the exhaust gases are low in oxygen,

so the sensor sends a low-voltage signal. The

voltage rises as the mixture weakens and the

amount of oxygen in the exhaust gases rises.

Peak conversion efficiency of all major

pollutants occurs if the inlet air/fuel mixture is

maintained at the chemically-correct ratio for

the complete combustion of petrol - 14.7

parts (by weight) of air to 1 part of fuel (the

“stoichiometric” ratio). The sensor output

voltage alters in a large step at this point, the

ECU using the signal change as a reference

point, and correcting the inlet air/fuel mixture

accordingly by altering the fuel injector pulse

width (the length of time that the injector is

open).

Evaporative emission control

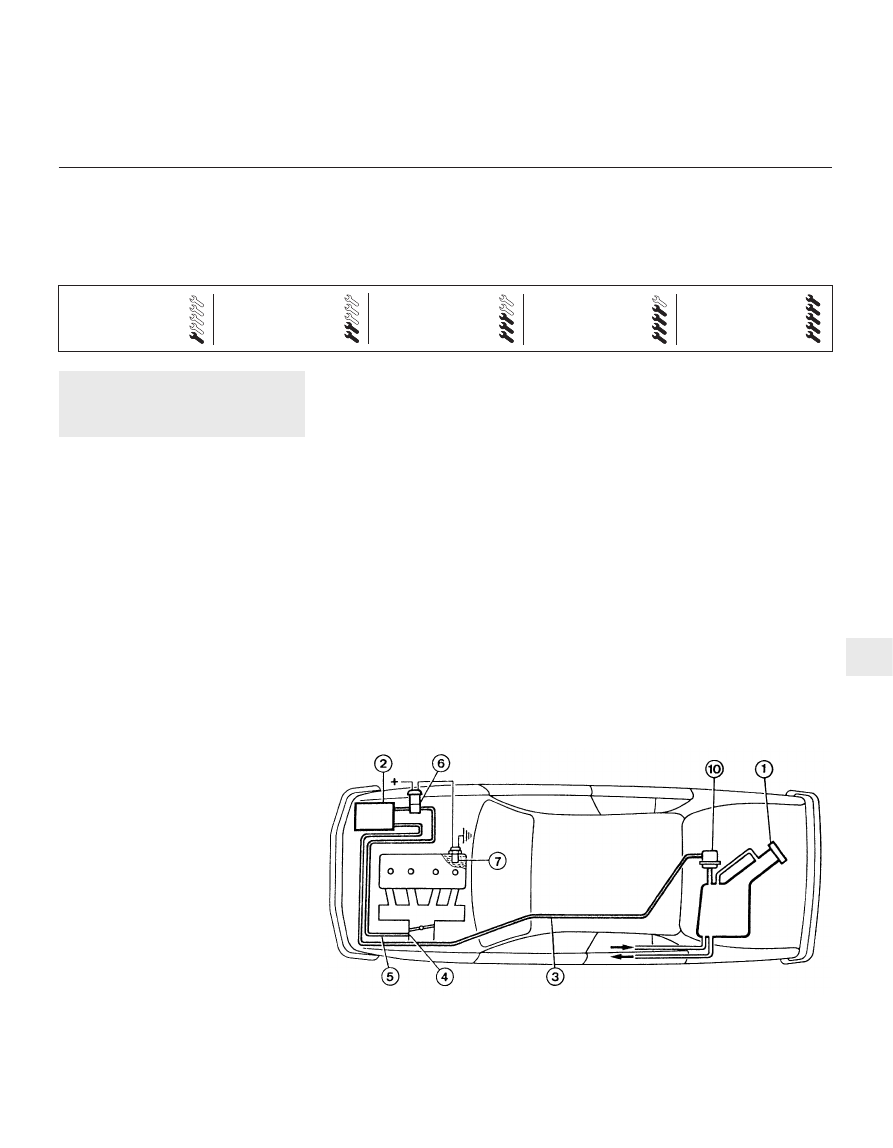

7 To minimise the escape into the

atmosphere of unburned hydrocarbons, an

evaporative emissions control system is fitted

to later models (see illustration). The fuel

tank filler cap is sealed, and a charcoal

canister, mounted underneath the front left-

hand wing, collects the petrol vapours

generated in the tank when the car is parked.

The canister stores them until they can be

cleared from the canister (under the control of

the fuel injection/ignition system ECU) via the

purge solenoid valve. When the valve is

opened, the fuel vapours pass into the inlet

tract, to be burned by the engine during

normal combustion.

8 To ensure that the engine runs correctly

when it is cold and/or idling, the ECU does not

1.7 Evaporative emissions control system

1 Fuel filler cap

2 Charcoal canister

3 Hose

4 Calibrated orifice

5 Hose

6 Solenoid valve

7 Coolant temperature

sensor

10 Safety valve