Peugeot 405 Haynes (petrol). Manual - part 15

1

General information and

precautions

The fuel system consists of a fuel tank

mounted under the rear of the car, a

mechanical fuel pump, and a carburettor. The

fuel pump is operated by an eccentric on the

camshaft, and is mounted on the rear of the

cylinder head. The air cleaner contains a

disposable paper filter element, and

incorporates a flap valve air temperature

control system; this allows cold air from the

outside of the car, and warm air from the

exhaust manifold, to enter the air cleaner in

the correct proportions.

The fuel pump lifts fuel from the fuel tank to

the carburettor via a filter located in the rear of

the engine compartment, and supplies it to the

carburettor via an anti-percolation chamber.

The anti-percolation chamber ensures that the

supply of fuel to the carburettor is kept at a

constant pressure, and is free of air bubbles.

Excess fuel is returned from the anti-

percolation chamber to the fuel tank.

The carburettor is either a Solex 34-34 Z1 or

Solex 32-34 Z2 twin-choke carburettor, or

Weber 36TLP single-choke carburettor (see

Section 11), mixture enrichment for cold starting

is by automatic choke on the Solex carburettor

and a cable-operated choke control on the

Weber carburettor. On the Solex carburettor a

vacuum-operated choke unloader, accelerator

pump and full load enrichener device are fitted

to govern the fuel requirements of the engine

over its full operating range.

The exhaust system consists of three or

four sections according to model. The front

pipe is in one or two sections; where it is in

two sections the rear section may be plain or

include a catalytic converter, where it is in one

section it may include a catalytic converter. All

models are fitted with an Intermediate pipe

and silencer, and a tailpipe and silencer. The

system is suspended throughout its entire

length by rubber mountings.

2

Air cleaner assembly -

removal and refitting

2

Removal

TU engine

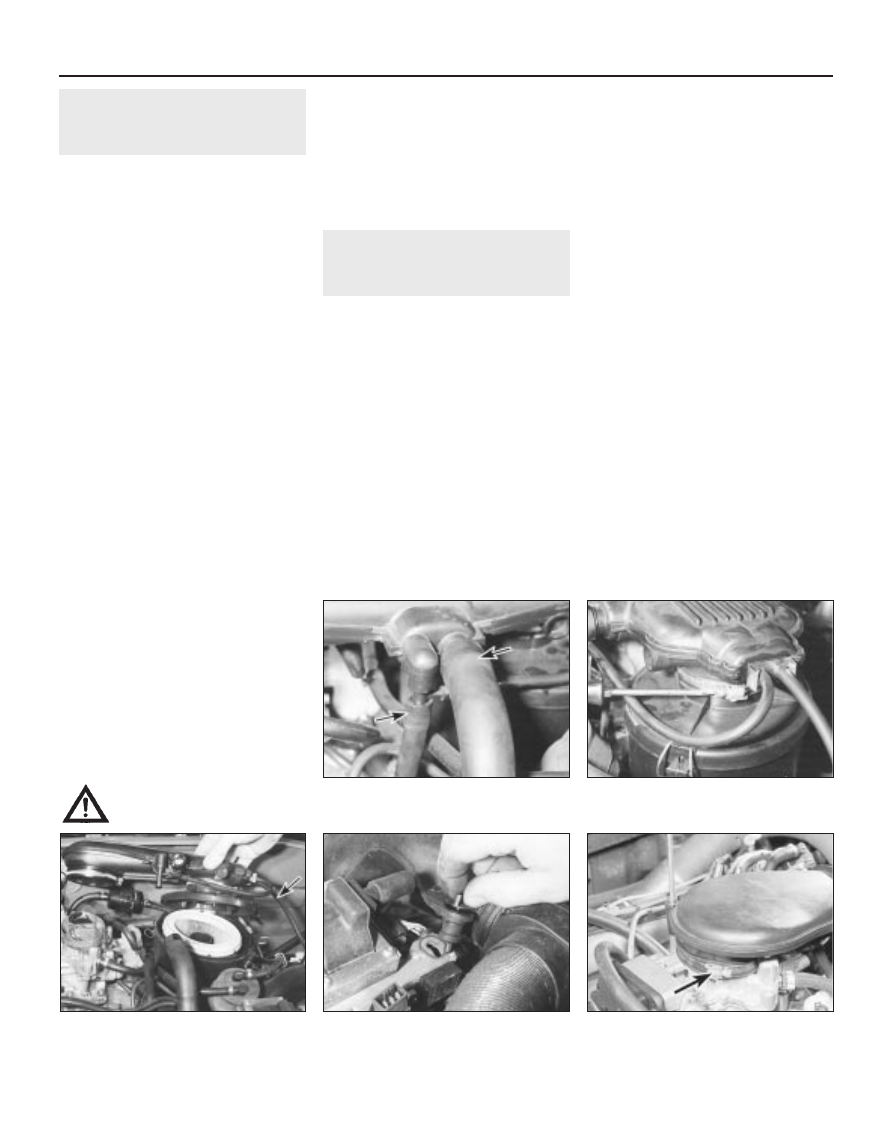

1 Slacken the retaining clips (where fitted),

and disconnect the vacuum hose and

breather hose from the front of the air cleaner

housing-to-carburettor duct (see illustration).

Where the crimped-type Peugeot hose clips

are fitted, cut the clips and discard them; use

standard worm-drive hose clips on refitting.

2 Slacken the retaining clips, then lift the duct

off the top of the carburettor and air cleaner

housing. Disconnect the air temperature

control valve hose from the end of the duct,

and remove the duct from the engine

compartment

(see illustrations). Recover the

rubber sealing ring(s) from the top of the

carburettor and/or air cleaner housing (as

applicable).

3 Disconnect the inlet duct from the front of

the air cleaner housing, and remove the air

cleaner housing from the engine

compartment.

4 To remove the inlet duct assembly, undo

the retaining bolts securing the duct to the

left-hand wing valance, then release the

fastener securing the rear of the duct to the

cylinder head (see illustration). Disconnect

the hot-air inlet hose from the exhaust

manifold shroud, and remove the duct and

hose assembly from the engine compartment.

XU engine

5 Using an Allen key, unscrew the bolt

securing the air inlet duct to the top of the

carburettor. Loosen the clip and disconnect

the duct (see illustration).

6 Loosen the clip and disconnect the air inlet

duct from the filter housing top cover.

7 Release the clips and remove the top cover

from the air filter housing.

8 Remove the filter element from inside the

lower housing.

9 Release the lower housing from the

mounting rubbers then disconnect the inlet

duct and hoses as applicable.

Refitting

10 Refitting is a reversal of the removal

procedure, noting the following points:

a) Examine the rubber sealing ring(s) for

signs of damage or deterioration, and if

necessary renew. Note that, on some

models, the carburettor seal is fitted with

an O-ring; this should also be renewed if

it is damaged.

4A•2 Fuel/exhaust systems - carburettor models

2.1 On the TU engine disconnect the

vacuum and breather hoses (arrowed)

from the front of the duct . . .

2.2b . . . and remove the duct,

disconnecting the air temperature control

valve hose (arrowed)

2.5 On the XU engine unscrew the bolt

securing the air inlet duct,

then loosen the clip

2.4 Undo the intake duct front bolt then

release the rear fastener, and remove the

duct and hose assembly (TU engine)

2.2a . . . slacken the retaining clips . . .

Warning: Many of the

procedures in this Chapter

require the removal of fuel lines

and connections, which may result in

some fuel spillage. Before carrying out

any operation on the fuel system, refer to

the precautions given in “Safety first!” at

the beginning of this manual, and follow

them implicitly. Petrol is a highly

dangerous and volatile liquid, and the

precautions necessary when handling it

cannot be overstressed.