Opel Frontera UBS. Manual - part 996

4A2A–38 DIFFERENTIAL (REAR 220mm)

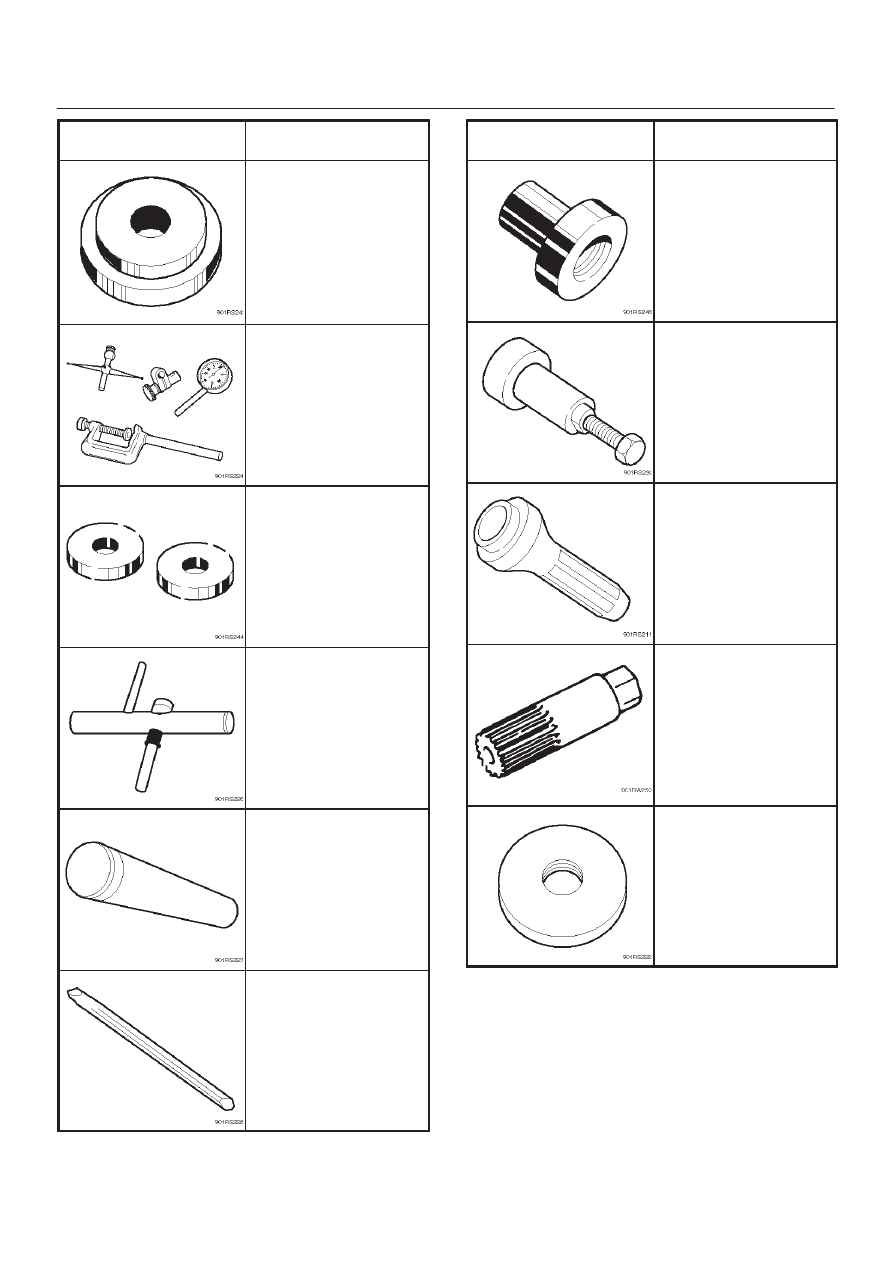

ILLUSTRATION

TOOL NO.

TOOL NAME

5–8840–2166–0

(J–23597–7)

Gauge plate

5–8840–0126–0

(J–8001)

Dial indicator

5–8840–2167–0

(J–23597–8)

Disc

5–8840–0128–0

(J–23597–1)

Arbor

9–8522–1165–0

(J–6133–01)

Installer; Pinion bearing

5–8840–2293–0

(J–39209)

Punch; End nut lock

ILLUSTRATION

TOOL NO.

TOOL NAME

5–8840–2162–0

(J–24244)

Installer; Side bearing

5–8840–2323–0

(J–39602)

Remover; Outer bearing

5–8840–2165–0

(J–37263)

Installer; Pinion oil seal

5–8840–2682–0

(J–44450)

Holder; Side gear

5–8840–0129–0

(J–23597–12)

Rear pilot