Opel Frontera UBS. Manual - part 993

4A2A–26 DIFFERENTIAL (REAR 220mm)

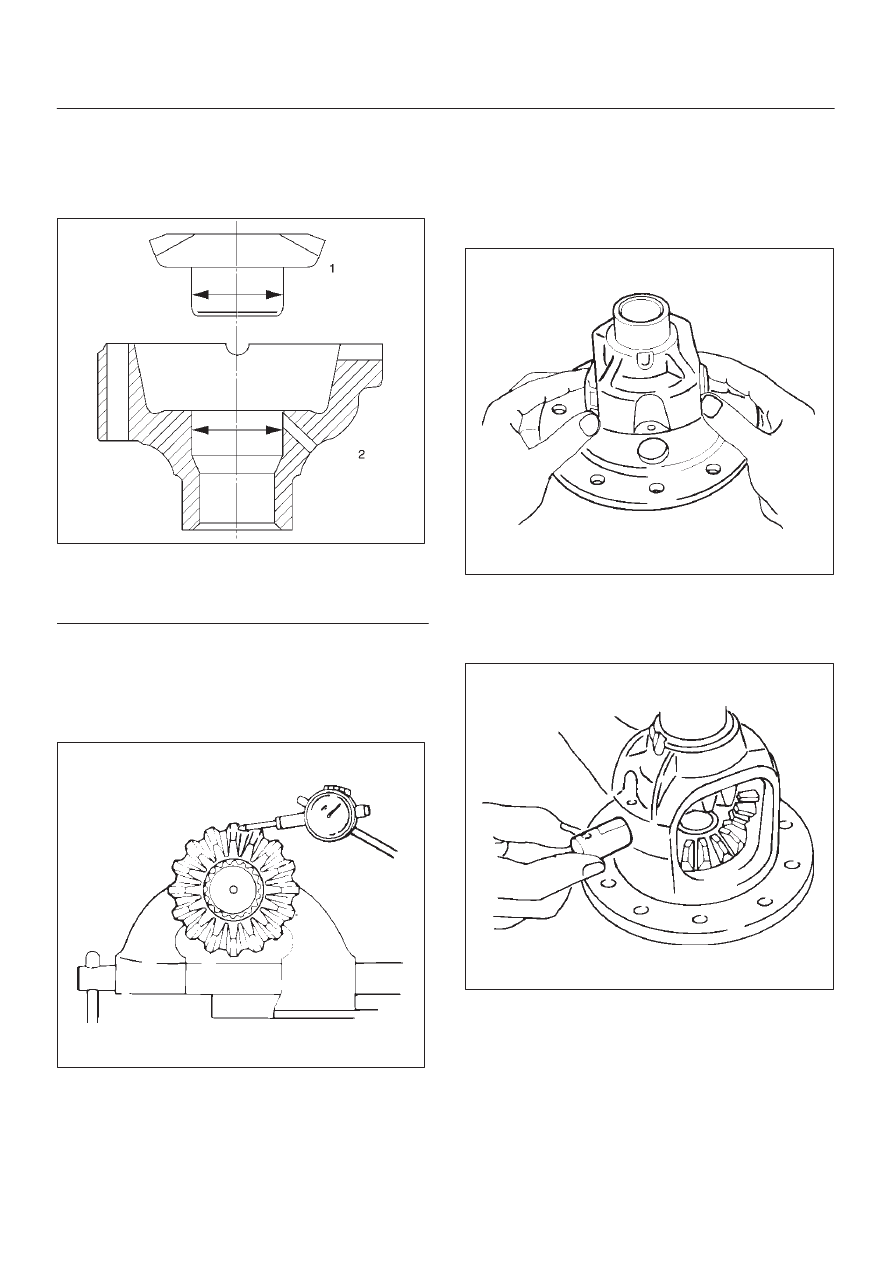

Clearance between the side gear and the

differential box:

Standard: 0.05–0.12 mm (0.002–0.005 in)

Limit: 0.15 mm(0.006 in)

425RS046

Legend

(1) Side Gear

(2) Differential Box

Play in splines between the side gear and

the axle shaft:

Standard: 0.07–0.38 mm(0.003 –0.014 in)

Limit:0.5m (0.02 in)

425RS047

Reassembly

1. Install thrust washer.

2. Install side gear.

3. Install the pinion gear by engaging it with the side

gears while turning both pinion gears simultaneously

in the same direction.

425RS048

4. Install cross pin.

1. Be sure to install the cross pin so that it is in

alignment with the lock pin hole in the differential

cage.

425RS049

2. Adjust the backlash between the side gear and

the pinion gear.

Backlash:0.13 – 0.18 mm (0.005– 0.007 in)