Opel Frontera UBS. Manual - part 947

6.

Tighten the lock nut to the specified torque.

Lock Nut Torque

N·m (kg·m/lb·ft)

23 (2.3 / 17)

2A – 6 FRONT END ALIGNMENT

4.

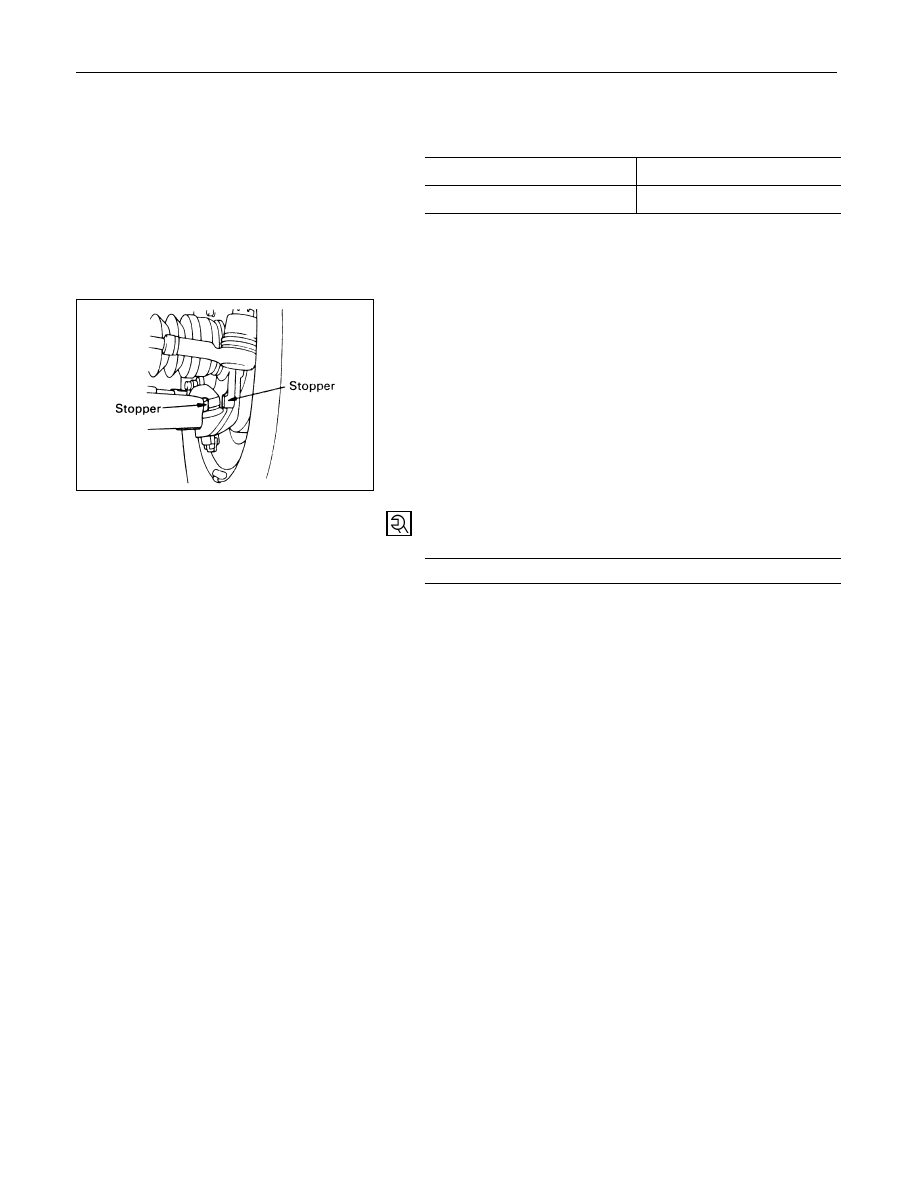

Similarly adjust the inside wheel angle of the other

side with stopper bolt.

Maximum Steering Angle

Inside wheel

34°

+0°

-2°

Outside wheel

32°

NOTE:

Maximum steering angles should be set after adjusting

front wheel alignment.

5.

If the stop between the lower link end and the knuckle

comes ahead of the stopper bolt, adjust the stopper

bolt so that inner stopper bolt touches the drop arm

(relay lever).