Opel Frontera UBS. Manual - part 713

8D–282

WIRING SYSTEM

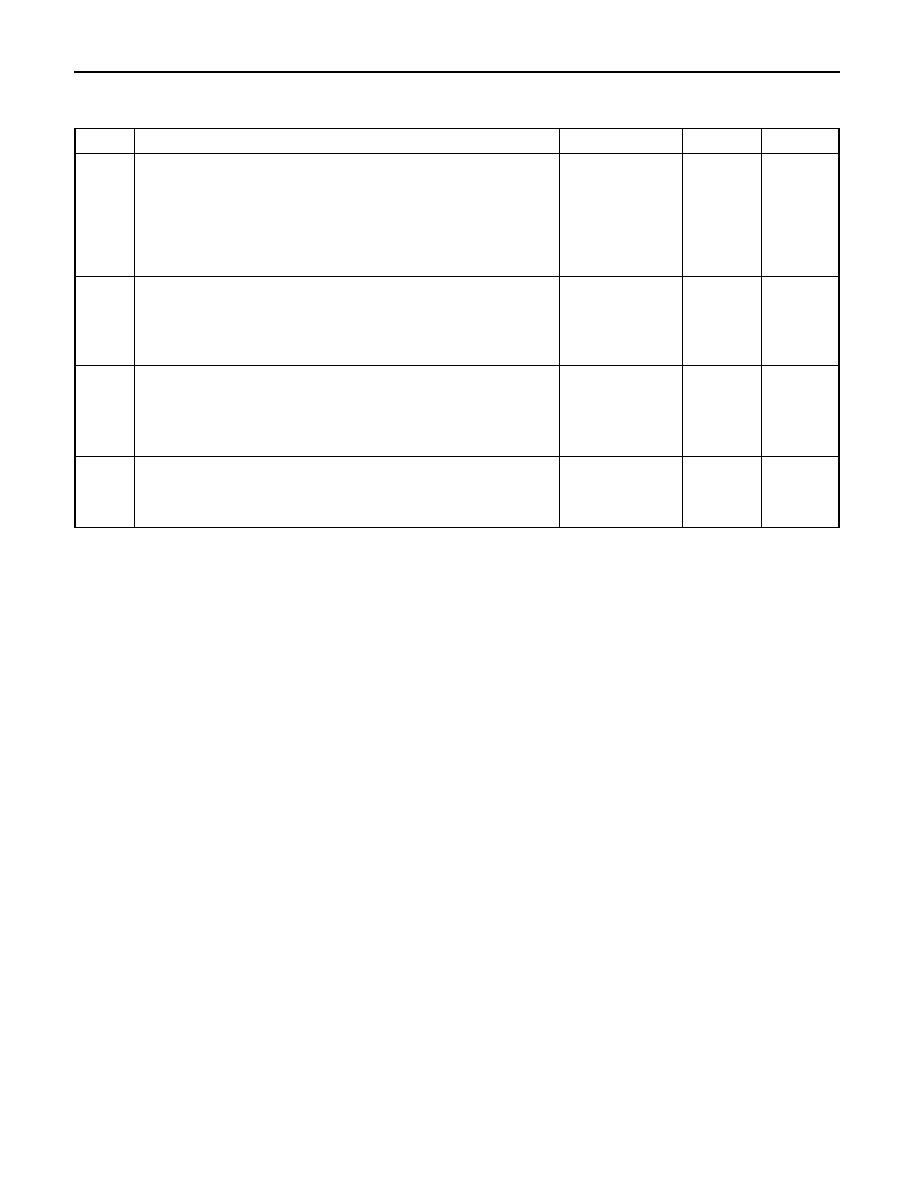

DTC 1–3 Mechanical Defect

STEP

ACTION

VALUE(S)

YES

NO

1. Turn the starter switch off.

2. Disconnect the actuator connector C–37.

3. Connect the battery positive terminal with the actuator side

connector terminal 3 and the battery negative terminal with

terminal 4.

Does the control plate move by hand?

Connect the battery positive terminal with the actuator side

connector terminal 1 and 3, and the battery negative terminal

with terminal 2 and 4.

Does the control plate move to full open side?

Connect the battery positive terminal with the actuator side

connector terminal 2 and 3, and the battery negative terminal

with terminal 1 and 4.

Does the control plate move to full close side?

Is there continuity between harness side connector C–37

terminal 1 and connector B–9 terminal 7, connector C–37

terminal 2 and connector B–9 terminal 15?

–

–

–

–

Replace

the

actuator

Go to

step 3

Go to

step 4

Replace

the control

unit

Go to

step 2

Replace

the

actuator

Replace

the

actuator

Repair or

replace

harness

1

2

3

4