Opel Frontera UBS. Manual - part 464

6D – 12 ENGINE ELECTRICAL

2) Inspect the brush springs for wear, damage or other

abnormal conditions.

Standard: 28 – 35 N (2.9 – 3.6 kg/6.4 – 7.9 lb)

Magnetic switch

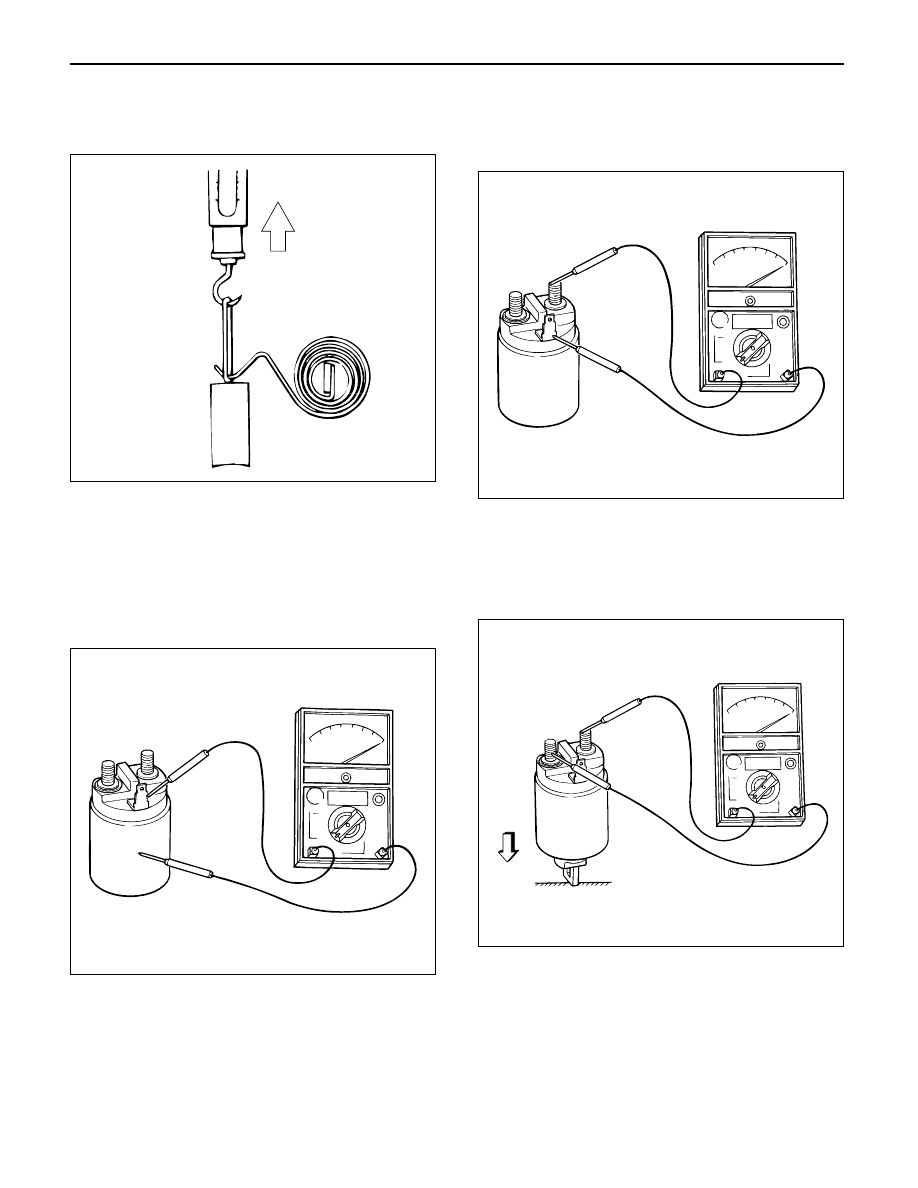

1) Continuity of shunt coil

Check for continuity between terminals S and coil

case.

Replace, if there is not continuity (i.e., coil is

disconnected.)

2) Continuity of series coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

3) Continuity of contacts

With the plunger faced downward, push down the

magnetic switch. In this state, check for continuity

between terminals B and M. Replace, if there is no

continuity (i.e., contacts are faulty).

065RW052

065RW017

065RW018

065RW016