Opel Frontera UBS. Manual - part 435

6A – 30 ENGINE MECHANICAL

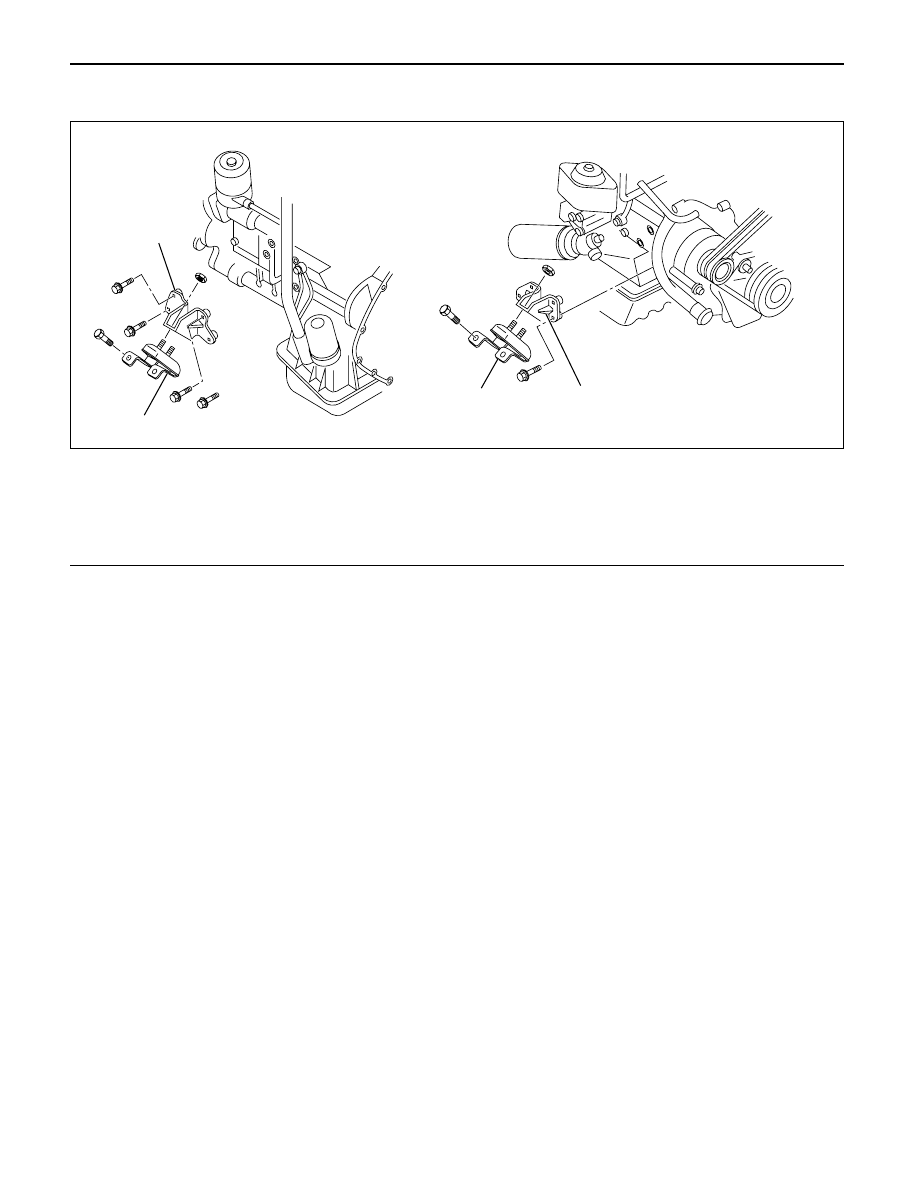

ENGINE MOUNT (RH)

REMOVAL

1. Disconnect battery ground cable

2. Hang the engine assembly.

3. Rubber engine mount.

1) Remove bolts from chassis frame bracket.

2) Remove nuts from rubber engine mount and

engine mounting bracket.

4. Remove bolt which is fixed between engine and

mounting bracket then remove the engine mounting

bracket.

INSTALLATION

•

Tighten the fixing bolts to the specified torque.

1. Engine mounting bracket to cylinder block.

Torque : 40 N·m (4 kg·m/29 lb ft) (for M10)

127 N·m (13 kg·m/94 lb ft) (for M14)

2. Rubber engine mount to chassis frame and engine

mounting bracket.

Torque :40 N·m (4 kg·m/29 lb ft)

4

3

1

2

022RW018

Legend

(1)

Rubber Engine Mount (LH)

(2)

Engine Mounting Bracket (LH)

(3)

Rubber Engine Mount (RH)

(4)

Engine Mounting Bracket (RH)