Opel Frontera UBS. Manual - part 395

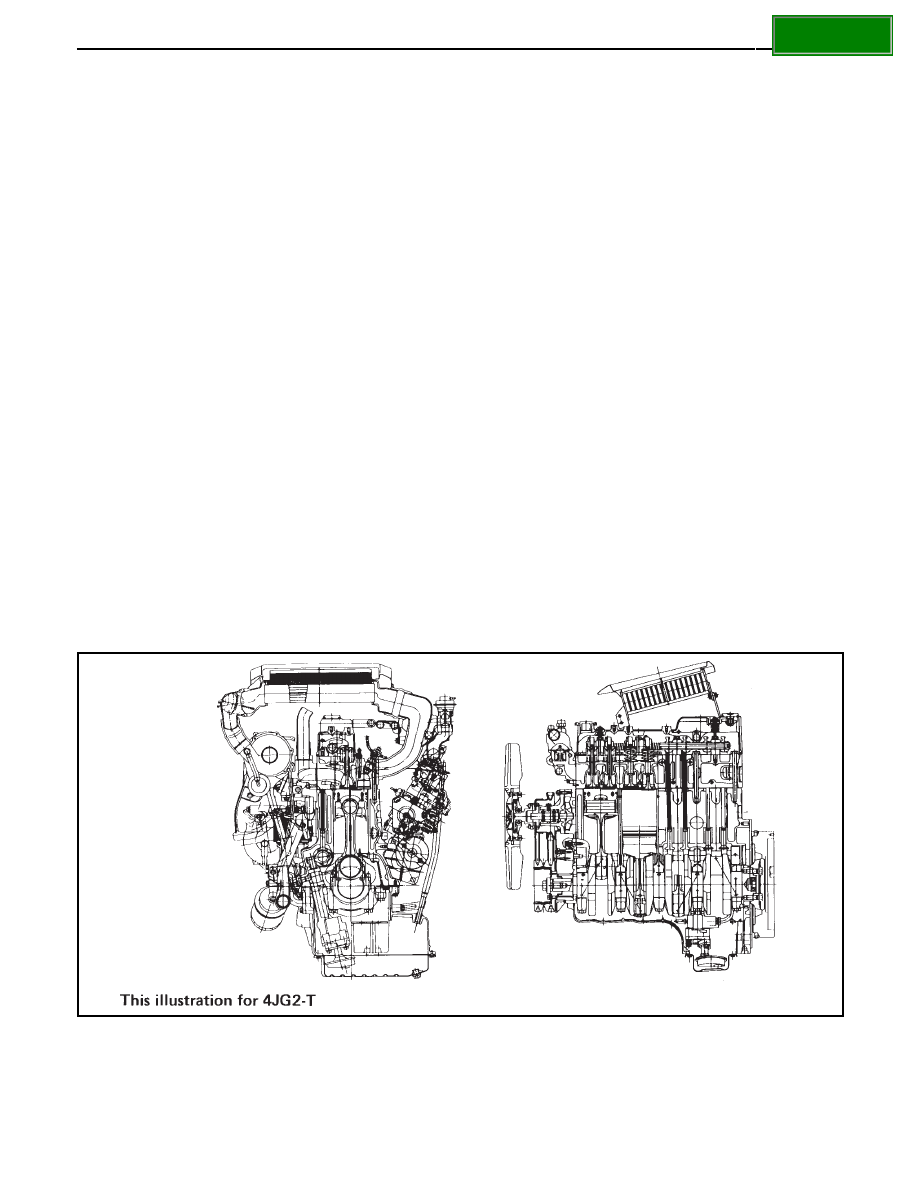

4JG2-NA/4JG2-TURBO ENGINE 6A2 – 1

SECTION 6A2

4JG2-NA/4JG2-TURBO ENGINE

CONTENTS

PAGE

General Description ..................................................................................................................... 6A2- 1

Engine Mount (RH) .................................................................................................................. 6A2- 3

Engine Mount (LH) .................................................................................................................. 6A2- 4

Intercooler (4JG2-T only) ........................................................................................................ 6A2- 5

Cylinder Head Cover ............................................................................................................... 6A2- 6

Inlet Manifold ........................................................................................................................... 6A2- 8

Exhaust Manifold .................................................................................................................... 6A2-10

Turbo Charger (4JG2-T only) .................................................................................................. 6A2-11

Timing Gear ............................................................................................................................. 6A2-15

Valve Stem Oil Seal and Valve Spring .................................................................................. 6A2-21

Rocker Arm Shaft Assembly .................................................................................................. 6A2-24

Cylinder Head .......................................................................................................................... 6A2-26

Crankcase ................................................................................................................................. 6A2-31

Oil Cooler.................................................................................................................................. 6A2-34

Oil Pump Assembly ................................................................................................................. 6A2-36

Piston, Piston Ring and Connecting Rod .............................................................................. 6A2-37

Crankshaft and Main Bearing ................................................................................................. 6A2-39

Front Oil Seal ........................................................................................................................... 6A2-45

Rear Oil Seal ............................................................................................................................ 6A2-46

Engine Assembly ..................................................................................................................... 6A2-48

GENERAL DESCRIPTION