Opel Frontera UBS. Manual - part 336

6E–250

ENGINE DRIVEABILITY AND EMISSIONS

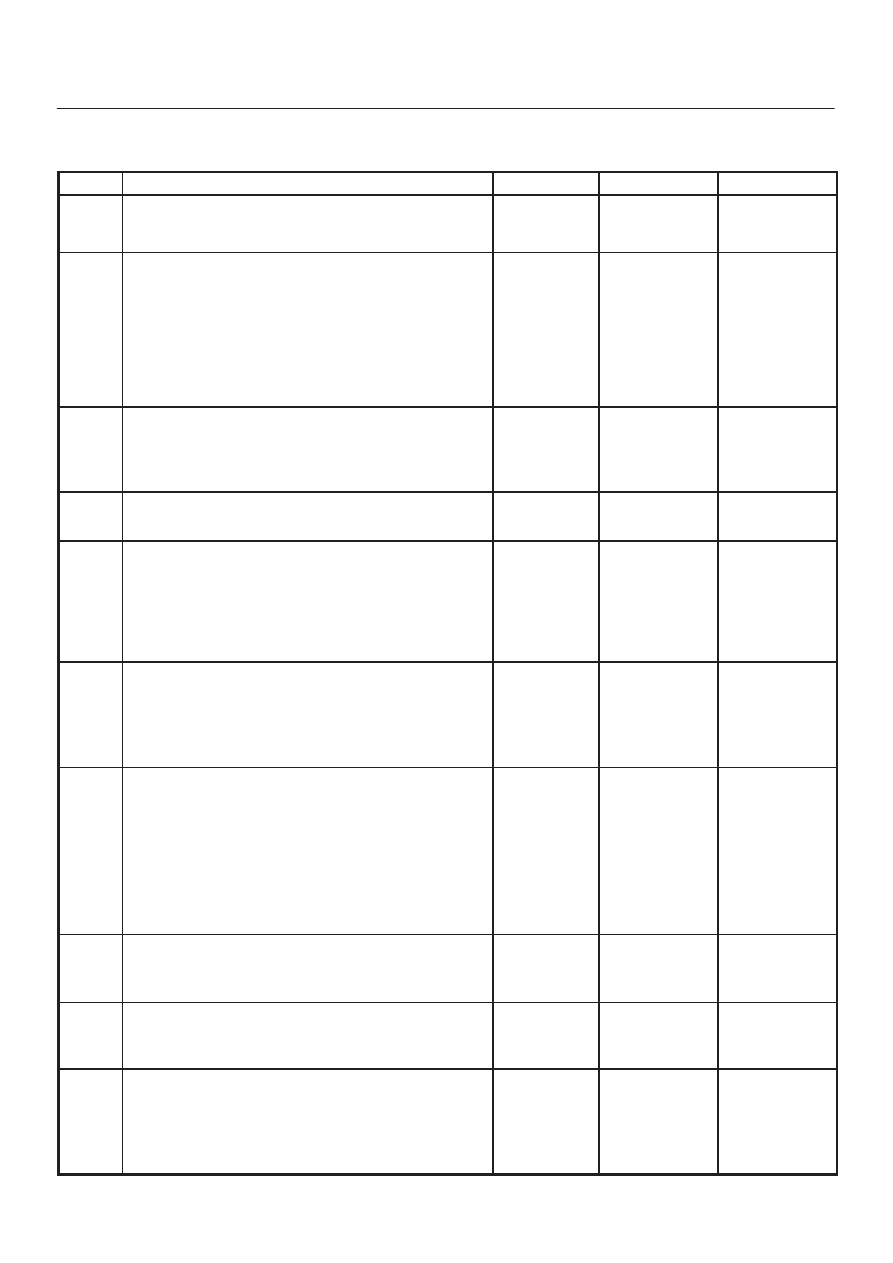

DTC P1404 – EGR Closed Stuck

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC inf. for DTC P1404

until the DTC P1404 test runs. Note the result.

Does the Tech 2 indicates DTC P1404 failed this

ignition?

—

Go to

Step 3

Refer to

Diagnostic

Aids

3

1. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—

Go to

Step 4

Go to

Step 5

4

Repair the damaged pin or terminal.

Is the action complete?

—

Verify repair

—

5

1. Remove EGR valve from Engine.

2. Inspect EGR valve whether there is any excessive

carbon deposit on EGR shaft.

3. Inspect any foreign material inside of EGR valve.

Was excessive carbon deposit on EGR valve shaft

or/and foreign material in EGR valve ?

—

Go to

Step 6

Go to

Step 7

6

1. Clean up EGR valve shaft and inside of EGR valve.

2. Remove foreign material from EGR valve.

3. Visually inspect damage of pintle and seat whether

there is bent, leakage may occur.

Was there any severe damage which affects function?

3–6 ohms

Go to

Step 8

Verify repair

Go to

Step 7

7

1. Reconnect.

2. Ignition “OFF”.

3. Install the Tech 2.

4. Run the engine at idle.

5. On the Tech 2, select F3:Misc. Test F5:EGR.

6. Use the “UP” arrow to increase the EGR from 0% to

40%.

Did EGR work properly?

—

—

Go to

Step 8

8

1. Reset the learned zero EGR valve position.

2. Repeat step 7.

Did EGR work properly?

—

Verify repair

Go to

Step 9

9

Replace the EGR valve.

Replace the EGR valve. Does DTC P1404 still fail

“specific DTC” test on the Tech 2?

—

Go to

Step 10

Verify repair

10

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?

—

Verify repair

—