Content .. 2922 2923 2924 2925 ..

Opel Frontera UBS. Manual - part 2924

SUPPLEMENTAL RESTRAINT SYSTEM

9J–49

10. Install glove box cover.

11. Install glove box assembly with lid.

12. Install ECM and SDM cover.

13. Install rear console assembly and connect harness

connector.

14. Install front console assembly.

15. Install gear control knob.

16. Enable the SRS (Refer to “Enabling the SRS” in this

section).

Pretensioner Seat Belt (If so equipped)

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND THE PRETENSIONER SEAT BELT OR THE

PRETENSIONER SEAT BELT WIRING, FOLLOW THE

PROCEDURES LISTED BELOW TO TEMPORARILY

DISABLE THE PRETENSIONER SEAT BELT.

FAILURE TO FOLLOW PROCEDURES COULD

RESULT IN POSSIBLE THE PRETENSIONER SEAT

BELT DEPLOYMENT, PERSONAL INJURY OR

OTHERWISE UNNEEDED THE PRETENSIONER

SEAT BELT REPAIR.

AS A PRECAUTION, WEAR GLOVES AND SAFETY

GLASSES WHEN PERFORMING THE

PRETENSIONER SEAT BELT. WHEN DEPLOY A LIVE

PRETENSIONER SEAT BELT AT OUTSIDE THE

VEHICLE, DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT WILL IMMEDIATELY DEPLOY WHEN A POWER

SOURCE IS CONNECTED TO IT. CONNECTING THE

DEPLOYMENT HARNESS SHOULED ALWAYS BE

THE FINAL STEP IN THE PRETENSIONER SEAT

BELT DEPLOYMENT PROCEDURE. FAILURE TO

FOLLOW PROCEDURES IN THE ORDER LISTED

COULD RESULT IN PERSONAL INJURY.

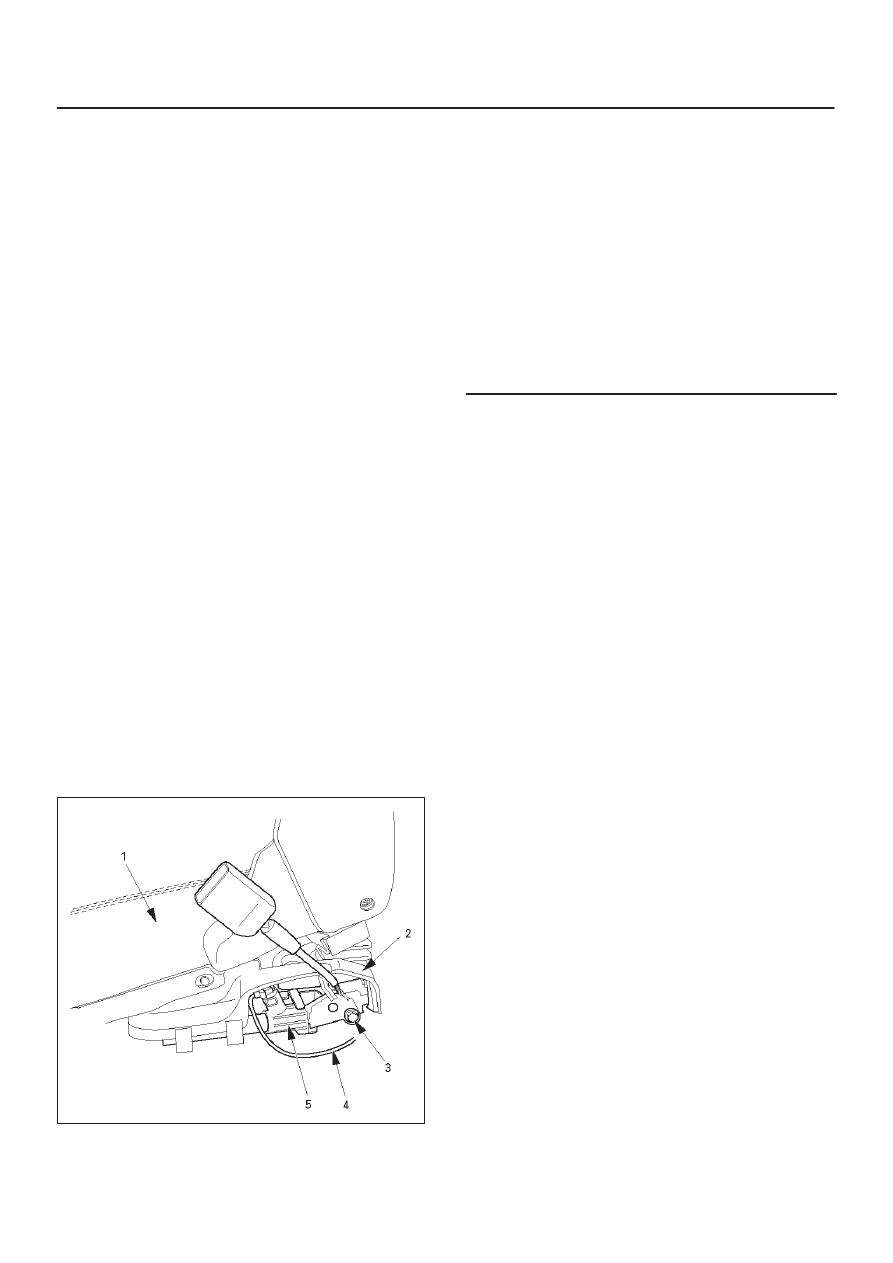

Parts Location

760RW028

Legend

(1) Seat

(2) Pretensioner Cover

(3) Bolt

(4) Pretensioner Harness

(5) Pretensioner

Removal

1. Turn ignition switch to “LOCK”, remove key.

2. Remove the foot rest located behind the seat.

3. Remove the cover on seat slide.

4. Disconnect the 2-pin connector at the base of the

seat.

5. Remove four fixing bolts the seat slide and remove

seat.

6. Remove the pretensioner seat belt cover.

7. Remove the pretensioner seat belt assembly.

Installation

1. Install the pretensioner seat belt assembly.

2. Install the pretensioner seat belt cover.

3. Install the seat on seat slide and four fixing bolts.

4. Connect the yellow 2-pin connector at the base of the

seat.

5. Install the cover on seat slide.

6. Install the foot rest located behind the seat.