Opel Frontera UBS. Manual - part 273

6D3–24 STARTING AND CHARGING SYSTEM

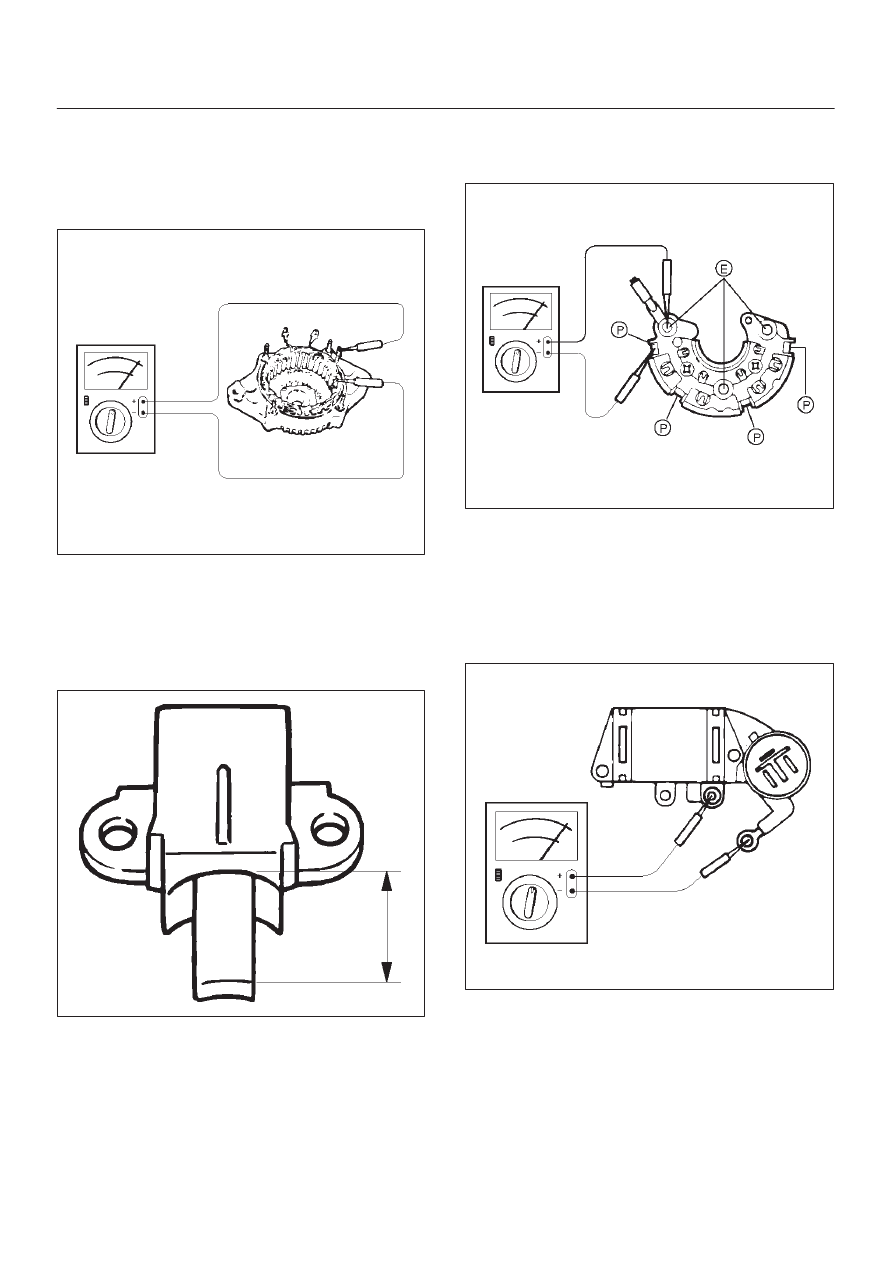

Stator Coil

1. Measure resistance between respective phases.

2. Measure insulation resistance between stator coil

and core with a mega–ohmmeter.

If less than standard, replace the coil.

066RS018

Brush

Measure the brush length.

If more than limit, replace the brush.

Standard: 10.mm (0.4134 in)

Limit: 8.4.mm (0.3307 in)

066RS019

Rectifier Assembly

Check for continuity across “P” and “E” in the

×

100W

range of multimeter.

066RW002

Change polarity, and make sure that there is continuity in

one direction, and not in the reverse direction. In case of

continuity in both directions, replace the rectifier

assembly.

IC Regulator Assembly

Check for continuity across “B” and “F” in the

×

100W

range of multimeter.

066RS021

Change polarity, and make sure that there is continuity in

one direction, and not in the reverse direction. In case of

continuity in both directions, replace the IC regulator

assembly.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points: