Content .. 2603 2604 2605 2606 ..

Opel Frontera UBS. Manual - part 2605

TRANSMISSION CONTROL SYSTEM (4L30–E)

7A1–71

DTC P1850 Brake Band Apply Solenoid Malfunction (Cont’d)

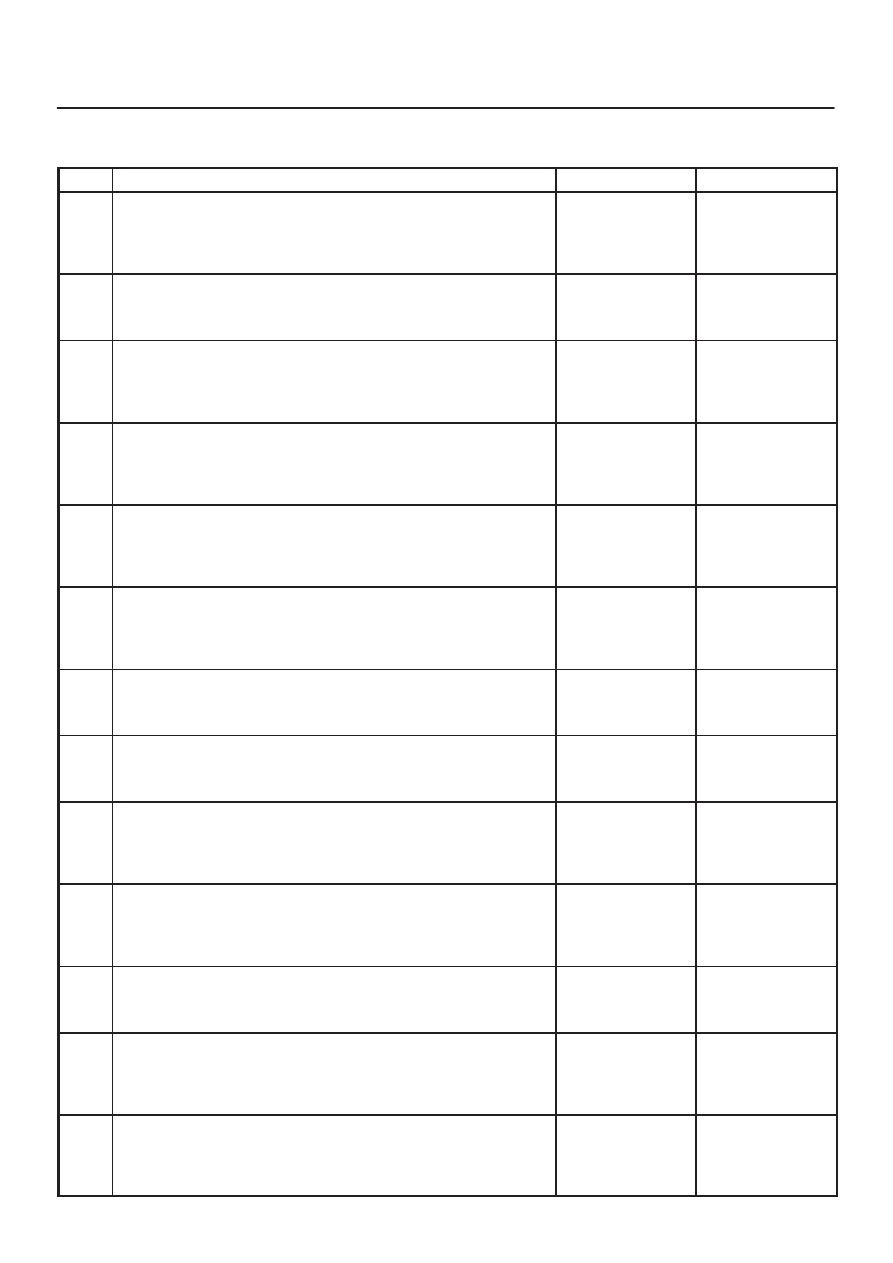

Step

No

Yes

Action

10

1. Disconnect the transmission main case connector M–7.

2. Using the J39200 DVOM, measure the resistance between

terminals M7–2(B) and M7–4(C).

Is the resistance within 10–12 ohms?

Go to Step 19

Go to Step 20

11

Using the J39200 DVOM, check continuity between PCM

terminal J1–A16 and ground.

Is there a continuity?

Go to Step 13

Go to Step 25

12

1. Disconnect the transmission 16–way connector H–53.

2. Using the J39200 DVOM, measure the resistance between

terminal H53–13 and H53–15.

Is the resistance within 10–12 ohms?

Go to Step 23

Go to Step 14

13

1. Disconnect the transmission 16–way connector H–53.

2. Using the J39200 DVOM, check continuity between terminal

H53–13 and ground.

Is there a continuity?

Go to Step 15

Go to Step 21

14

1. Disconnect the transmission main case connector M–7.

2. Using the J39200 DVOM, measure the resistance between

terminals M7–2(B) and M7–4(C).

Is the resistance within 10–12 ohms?

Go to Step 24

Go to Step 20

15

1. Disconnect the transmission main case connector M–7.

2. Using the J39200 DVOM, check continuity between the

terminal M7–2(B) and ground.

Is there a continuity?

Go to Step 17

Go to Step 22

16

The wiring harness between PCM terminal J3–E14 and

transmission 16–way connector terminal H53–15 is open.

Was a problem found and corrected?

Go to Step 26

—

17

The brake band apply solenoid is faulty, or the internal wiring

harness from the brake band apply solenoid is shorted to ground.

Was a problem found and corrected?

Go to Step 26

—

18

The wiring harness between the transmission 16–way connector

terminal H53–15 and the transmission main case connector

terminal M7–4(C) is shorted to ground.

Was a problem found and corrected?

Go to Step 26

—

19

The wiring harness between the transmission 16–way connector

terminal H53–15 and the transmission main case connector

terminal M7–4(C) is open.

Was a problem found and corrected?

Go to Step 26

—

20

The brake band apply solenoid is faulty, or the internal wiring

harness from the brake band apply solenoid is open.

Was a problem found and corrected?

Go to Step 26

—

21

The wiring harness between the PCM connector terminal J1–A16

and transmission 16–way connector terminal H53–13 is shorted

to ground.

Was a problem found and corrected?

Go to Step 26

—

22

The wiring harness between the transmission 16–way connector

terminal H53–13 and the transmission main case connector

terminal M7–2(B) is shorted to ground.

Was a problem found and corrected?

Go to Step 26

—