Content .. 2523 2524 2525 2526 ..

Opel Frontera UBS. Manual - part 2525

7A–58

AUTOMATIC TRANSMISSION (4L30–E)

D

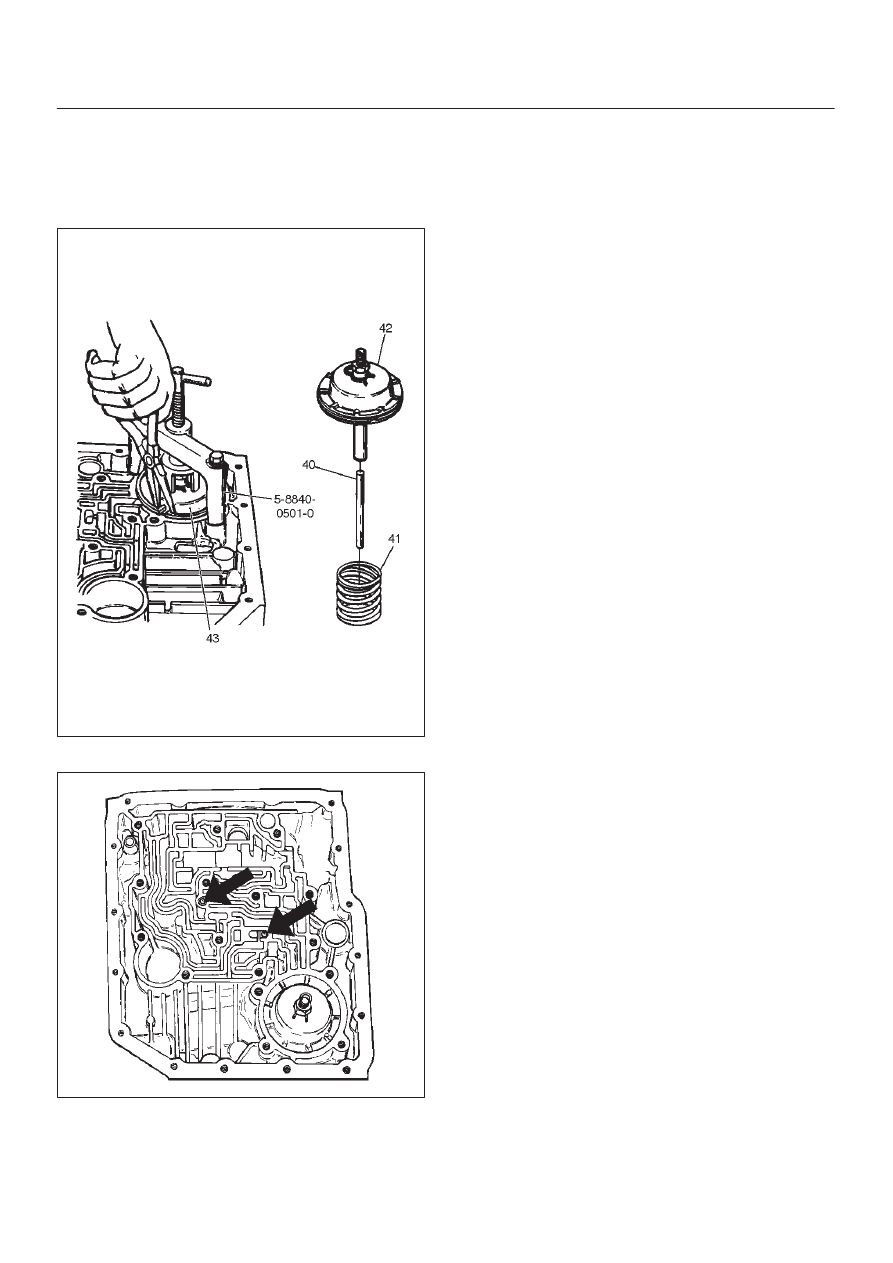

Adjust the brake band by tightening the servo

adjusting screw to 4.5 N·m torque. Be certain the

lock nut is loose, then back–off the screw five turns

exactly. Hold piston sleeve with wrench and tighten

lock nut to 18.5 N·m torque. Be certain the adjusting

screw does not turn.

242RW008

46. Install two check balls (44).

244RW002

47. Inspect main case electrical connector and seal,

replace if necessary.

D

Install electrical 7 way connector/main case and

wiring harness.

48. Install two 5–8840–0022–0 (J–25025–B) guide pins

into main case.

D

Install main case valve body complete assembly

(45) and manual valve link.

NOTE: Valve must be extended as the short end of

manual valve link is connected to the range selector lever.

Long end of link goes into valve.

D

Install seven 13 mm screws.

Torque: 20 N

•

m (2.0 kg·m/15 Ib ft)

D

Remove two guide pins.

49. Install servo cover gasket, cover (46) and four 13 mm

screws.

Torque: 25 N

•

m (2.6 kg·m/18 Ib ft)

50. Connect wiring harness (47) to band control, shift

solenoids, and main case 7 way connector.

51. Install manual detent roller and spring assembly (48)

with clip.

D

Install two 13 mm screws.

Torque: 20 N

•

m (2.0 kg·m/15 Ib ft)

52. Install oil filter (49), and three 13 mm screws.

Torque: 20 N

•

m (2.0 kg·m/15 Ib ft)

53. Install oil pan gasket, magnet, main oil pan (50), and

sixteen 10 mm screws.

Torque: 11 N

•

m (1.1 kg·m/96 Ib in)

54. Inspect adapter case electrical connector and seal.

Replace if necessary.

D

Install electrical five pin connector and harness

assembly (52) in bottom of adapter case.

55. Install gasket, transfer plate, and gasket.

D

Install adapter case valve body (51) and seven 13

mm screws.

Torque: 20 N

•

m (2.0 kg·m/15 Ib ft)

56. Connect wiring harness harness assembly (52) to

converter clutch PWM solenoid, force motor, and 4

way connector.

57. Install oil pan gasket, adapter case oil pan (53), and

twelve 10 mm screws.

Torque: 11 N

•

m (1.1 kg·m/96 Ib in)

D

Rotate transmission, with bottom pan facing down.

58. Install mode switch (54), two 10 mm screws, selector

lever nut, and cover.

10 mm screw

Torque: 13 N

•

m (1.3 kg·m/113 Ib in)

Nut

Torque: 23 N

•

m (2.3 kg·m/17 Ib ft)

D

Adjust using setting tool, refer to Mode Switch in

this section.