Opel Frontera UBS. Manual - part 252

6A–75

ENGINE MECHANICAL

4. Piston and connecting rod assembly (8)

D

Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins.

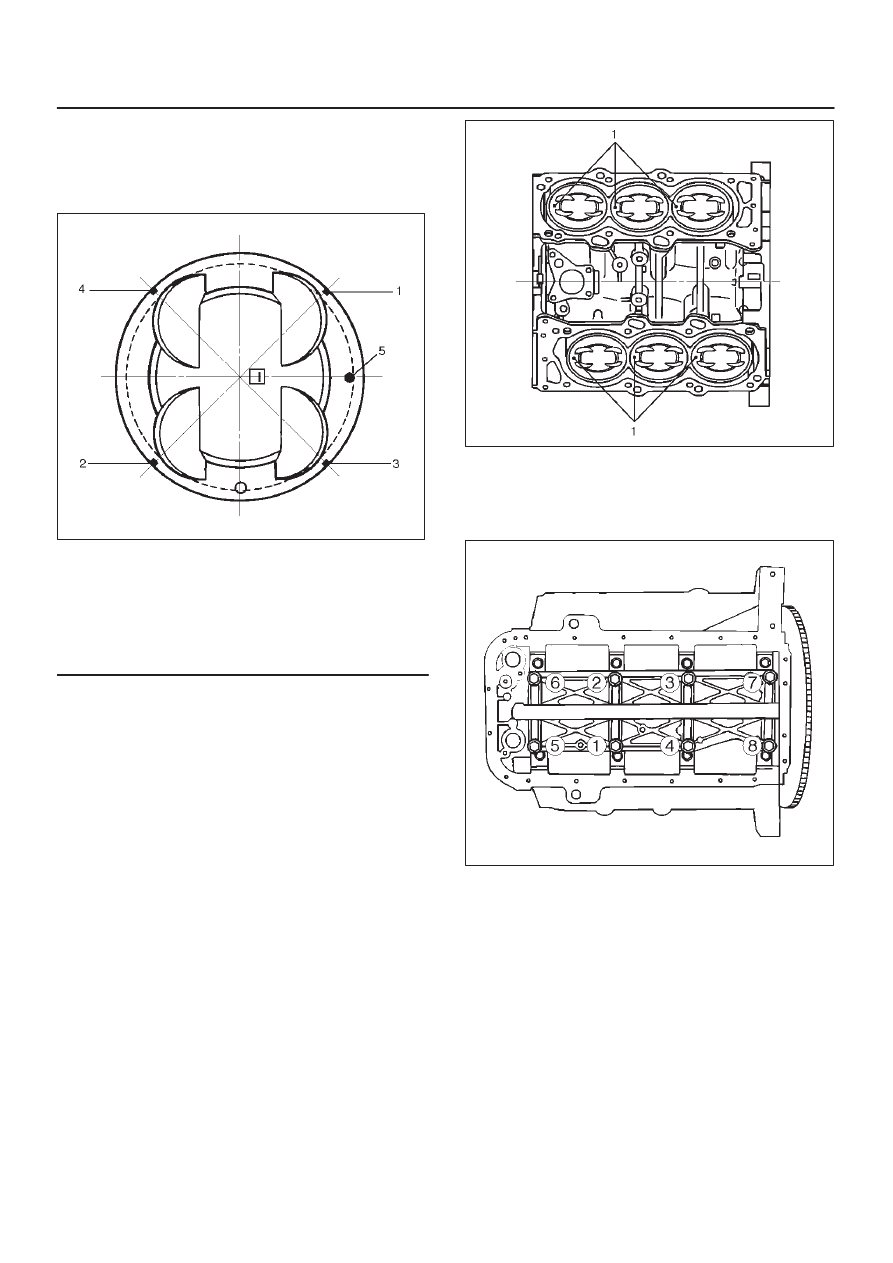

Check to see that the piston ring end gaps are

correctly positioned.

015RS019

Legend

(1) No.1 Compression Ring

(2) No.2 Compression Ring

(3) Oil Ring Side Rail Upper

(4) Oil Ring Side Rail Lower

(5) Piston Front Mark

D

Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor. The

front marks must be facing the front of the engine.

D

Match the numbered caps with the numbers on the

connecting rods. Align the punched marks on the

connecting rods and caps.

D

Apply engine oil to the threads and seating faces of

the nuts.

D

Tighten the nuts.

Torque: 54 N·m (5.5 Kg·m/40 lb ft)

After tightening the cap nuts, check to see that the

crankshaft rotates smoothly.

NOTE: Do not apply engine oil to the bearing back faces.

015RS020

5. Install oil gallery (7) and tighten the bolts in 2 steps, in

the order shown.

1st step: 29 N·m (3.0 Kg·m/22 lb ft)

2nd step: 55

°

∼

65

°

051RS009

6. Cylinder block side bolts (6)

D

Tighten all the bolts to the specified torque in the

order shown.

NOTE: Do not apply engine oil to the crank case side

bolts.

Torque: 39 N·m (4.0 Kg·m/29 lb ft)