Content .. 2515 2516 2517 2518 ..

Opel Frontera UBS. Manual - part 2517

7A–26

AUTOMATIC TRANSMISSION (4L30–E)

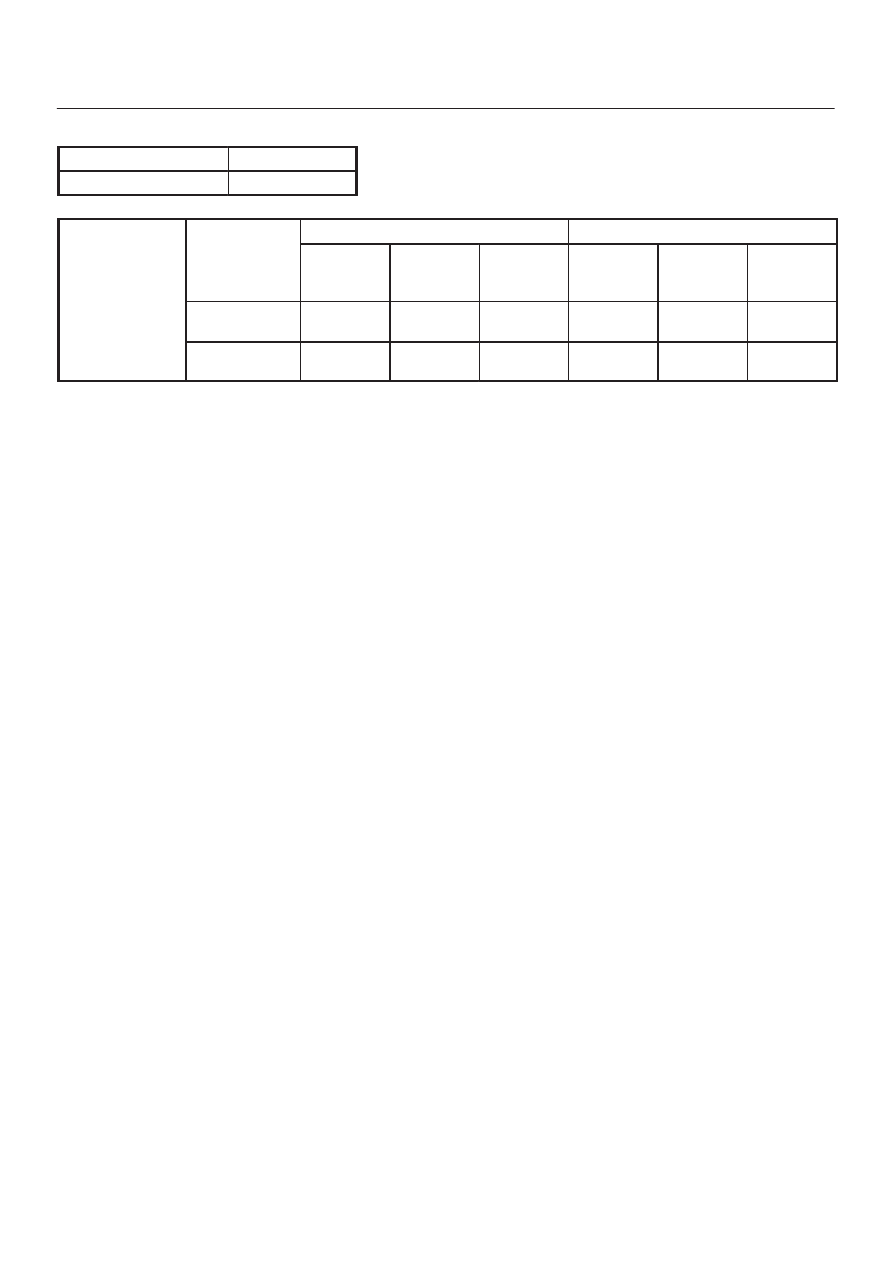

Lockup Speed Chart

Transfer gear ratio

High: 1.000

Rear axle ratio

4.100

ECCC Apply

ECCC Release

D range Throttle

i

6%

Mode

2nd

Km/h

(mph)

3rd

Km/h

(mph)

4th

Km/h

(mph)

2nd

Km/h

(mph)

3rd

Km/h

(mph)

4th

Km/h

(mph)

opening 6%

Normal

57

∼

63

(35

∼

39)

42

∼

48

(26

∼

30)

43

∼

49

(27

∼

31)

52

∼

58

(32

∼

36)

32

∼

38

(20

∼

24)

41

∼

47

(25

∼

29)

Power

57

∼

63

(35

∼

39)

67

∼

73

(42

∼

45)

57

∼

63

(35

∼

39)

52

∼

58

(32

∼

36)

32

∼

38

(20

∼

24)

49

∼

55

(30

∼

34)