Opel Frontera UBS. Manual - part 248

6A–59

ENGINE MECHANICAL

Limit: 39.47 mm (1.5539 in)

Exhaust

Standard: 39.30 mm (1.5472 in)

Limit: 39.45 mm (1.5531 in)

014RW047

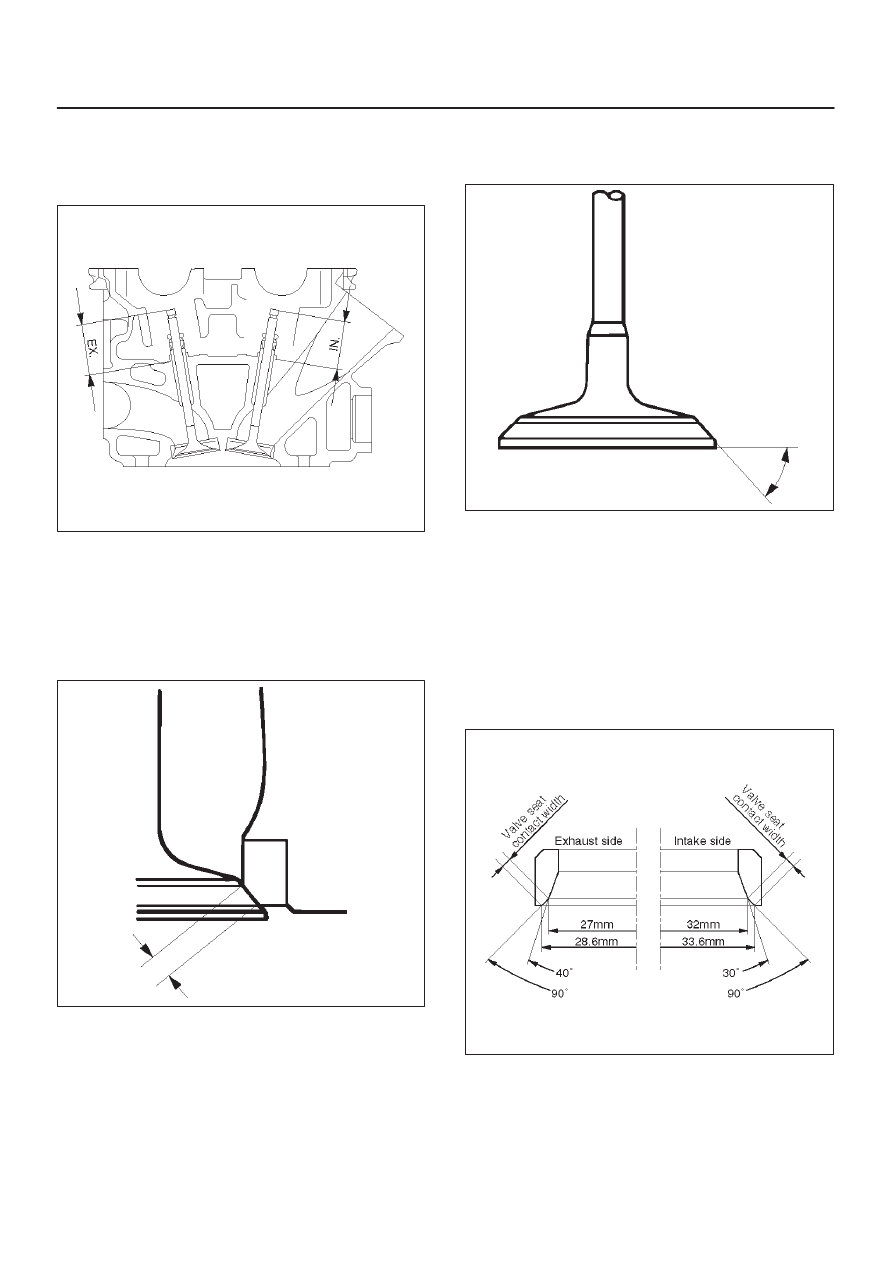

2. Measure the valve seat contact width. Make the

necessary corrections if the seat contact surface is

damaged or rough or if the contact width wear

exceeds the limit.

Valve seat contact width

Standard: 1.1 mm (0.0433 in)

Limit: 1.7 mm (0.0669 in)

014RS011

Contact Surface Angle on Valve Seat on

Valve

1. Measure contact surface angle on valve seat.

2. If the measured value exceeds the limit, replace

valve, valve guide and valve seat as a set.

Valve contact surface angle: 45

°

014RS012

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert

surface.

2. Use a valve cutter to minimize scratches and other

rough areas. This will bring the contact width back to

the standard value. Remove only the scratches and

rough areas. Do not cut away too much. Take care not

to cut away unblemished areas of the valve seat

surface.

Valve seat angle degree: 90

°

014RW059

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while lapping it to fit the valve seat

insert.