Opel Frontera UBS. Manual - part 245

6A–47

ENGINE MECHANICAL

Rear Oil Seal

Removal

1. Remove transmission assembly.

D

Refer to removal procedure for Transmission

section in this manual.

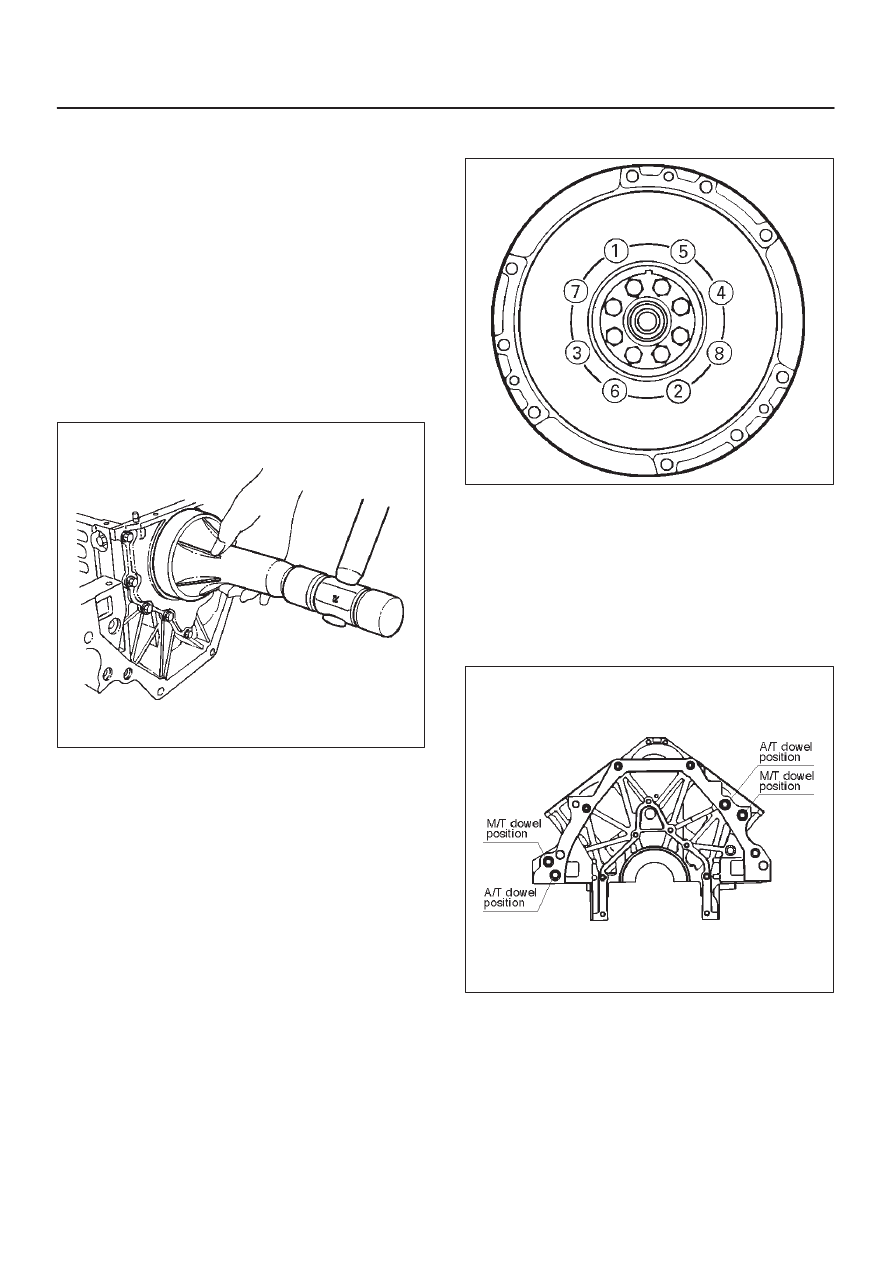

2. Remove flywheel.

3. Remove rear oil seal using a seal remover.

NOTE: Take care not to damage the crankshaft or oil seal

retainer when removing oil seal.

Installation

1. Apply engine oil to oil seal lip and install oil seal using

5–8840–2286–0.

015RS017

2. Install flywheel.

D

Clean tapped holes in the crankshaft.

D

Remove oil on the crankshaft and flywheel

mounting surface.

D

Tighten fixing bolts to the specified torque.

NOTE: Do not reuse the bolts and do not apply oil or

thread lock to the bolts.

Torque : 54 N·m (5.5 Kg·m/40 lb ft)

015RS018

3. Install transmission.

D

See Transmission section in this manual.

CAUTION: When assembling the engine and

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side. Take care that dowel positions are different

between the manual transmission and the automatic

transmission.

Otherwise, the transmission may be damaged.

012RS009