Content .. 2432 2433 2434 2435 ..

Opel Frontera UBS. Manual - part 2434

6E–50

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

(Cont'd)

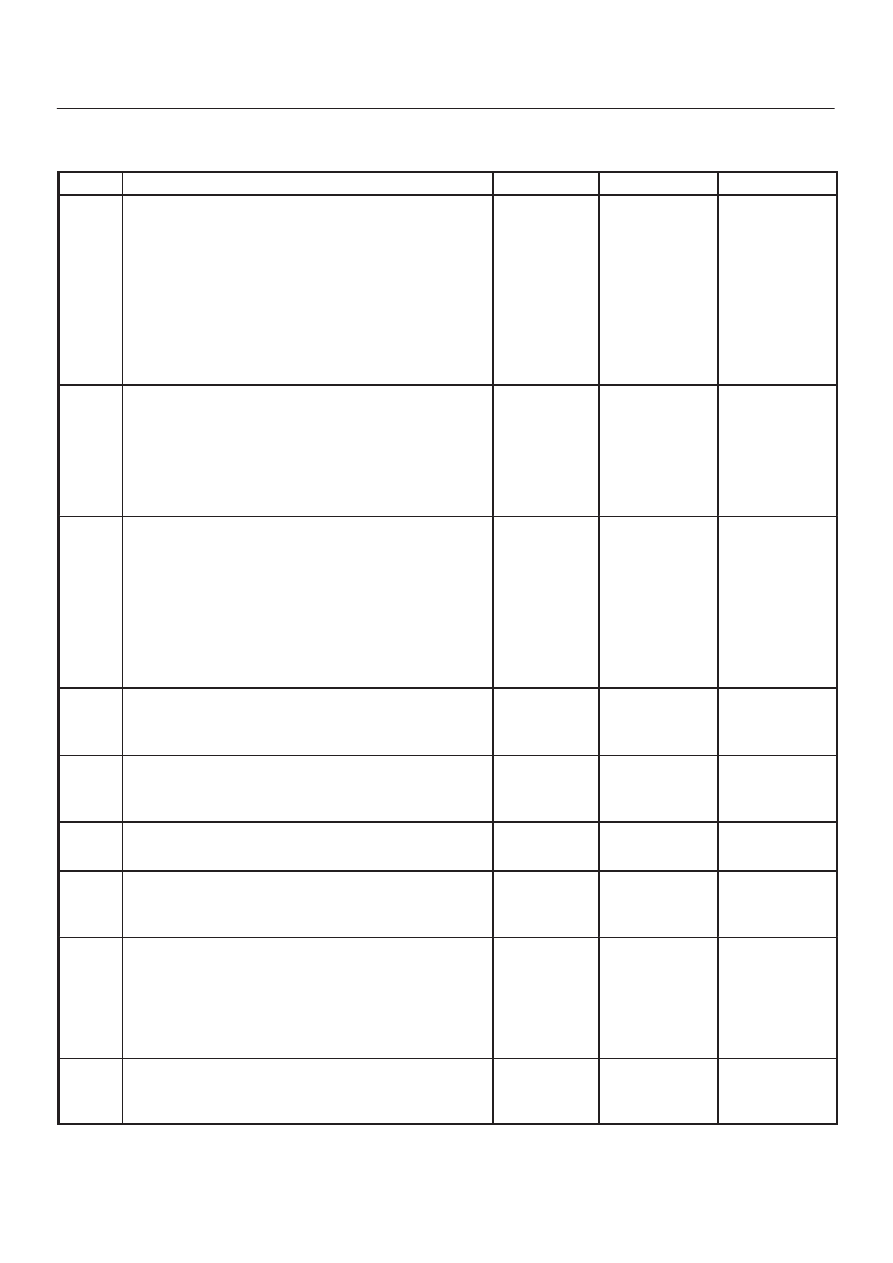

Step

No

Yes

Value(s)

Action

10

Refer to

Engine Mechanical Diagnosis to diagnose the

following conditions:

D

Faulty camshaft drive belts

D

Leaking or sticky valves or rings

D

Excessive valve deposits

D

Weak valve springs

D

Incorrect valve timing

D

Leaking head gasket

Is the action complete?

—

Verify repair

Go to

Step 11

11

Observe the “Engine Speed” data display on the Tech 2

while cranking the engine.

Is the engine RPM indicated? (If the Tech 2 is normally

powered from the cigarette lighter socket, and if the

Tech 2 display goes blank while cranking the engine, it

will be necessary to power the Tech 2 directly from the

vehicle battery.)

—

Go to

Step 12

Go to

Step 17

12

1. At the ECM (female) side of the connector

mentioned in step, connect a test light between the

ignition + terminal and one of the injector driver

circuits at the same connector.

2. Ignition “ON.”

3. Observe the test light, and repeat the test for each

injector driver circuit by oscilloscope.

Did the test light stay on when checking any of the 4

injector driver circuits?

—

Go to

Step 13

Go to

Step 15

13

1. Ignition “OFF,” disconnect the ECM.

2. Ignition “ON,” observe the test light.

Is the test light “ON?”

—

Go to

Step 14

Go to

Step 16

14

Locate and repair the short to ground in the injector

driver circuit.

Is the action complete?

—

Verify repair

—

15

Check for an open injector driver circuit.

Was a problem found?

—

Verify repair

Go to

Step 16

16

Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—

Verify repair

—

17

1. Raise the vehicle and disconnect the CKP sensor

harness.

2. Ignition “ON.”

3. With a test light to ground, probe the harness

ignition feed terminal.

Did the light illuminate?

—

Go to

Step 19

Go to

Step 18

18

Check the ignition feed wire between the sensor and

the ECM for a short to ground or open circuit.

Is the action complete?

—

Verify repair

—