Content .. 2425 2426 2427 2428 ..

Opel Frontera UBS. Manual - part 2427

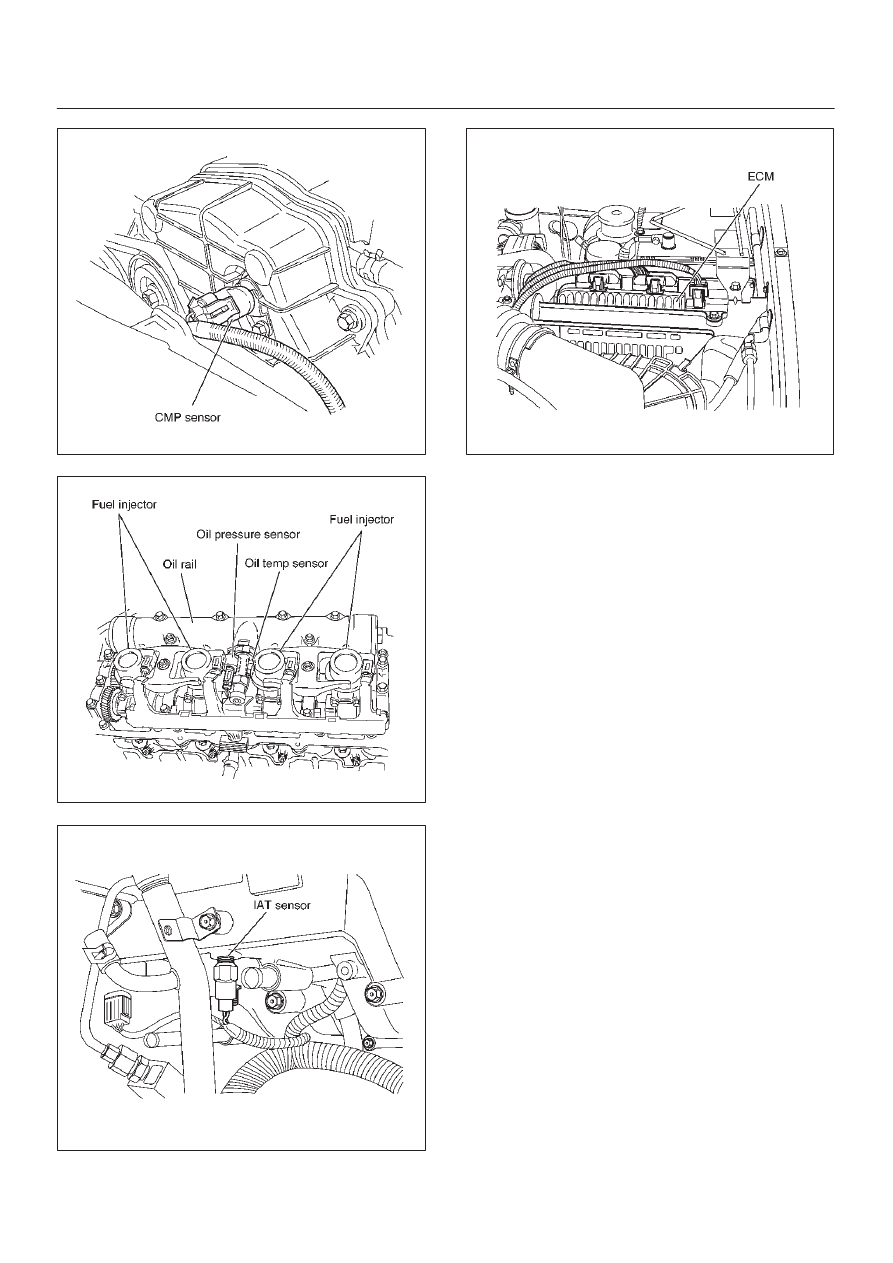

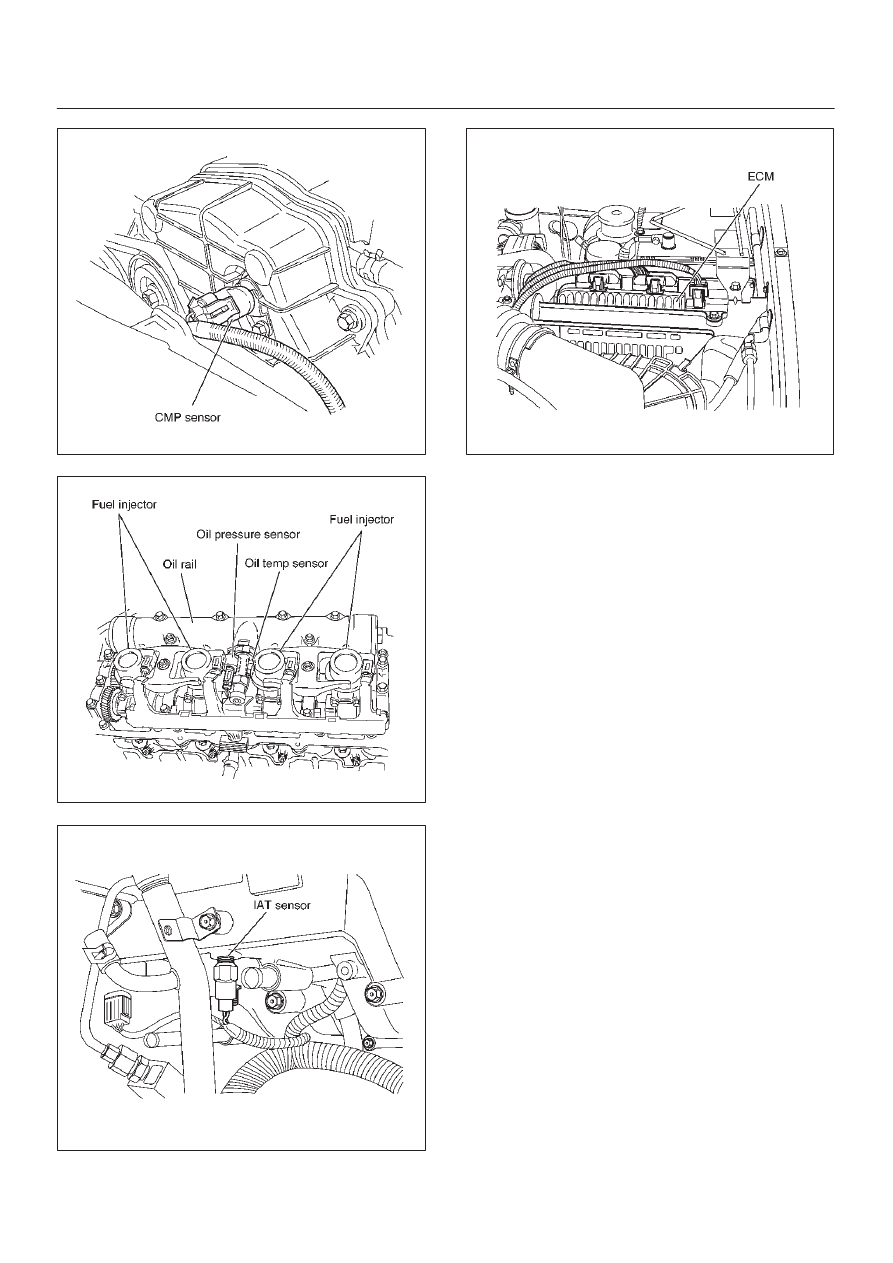

6E–22

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

035RW121

035RW122

035RW116

035RW107

|

|

|

Content .. 2425 2426 2427 2428 ..

6E–22 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS 035RW121 035RW122 035RW116 035RW107 |