Content .. 2412 2413 2414 2415 ..

Opel Frontera UBS. Manual - part 2414

6C – 18 ENGINE FUEL

4. Remove lock bolt of idle gear A.

5. Install timing gear case cover.

Refer to “Timing gear” in this manual.

6. Install front plate.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

7. Install timing pulley of high pressure oil pump.

Torque: 10 N·m (1.0 kg·m/87 lb in)

8. Install timing belt and tighten timing belt tensioner

assembly.

Refer to “Cylinder head” in this manual.

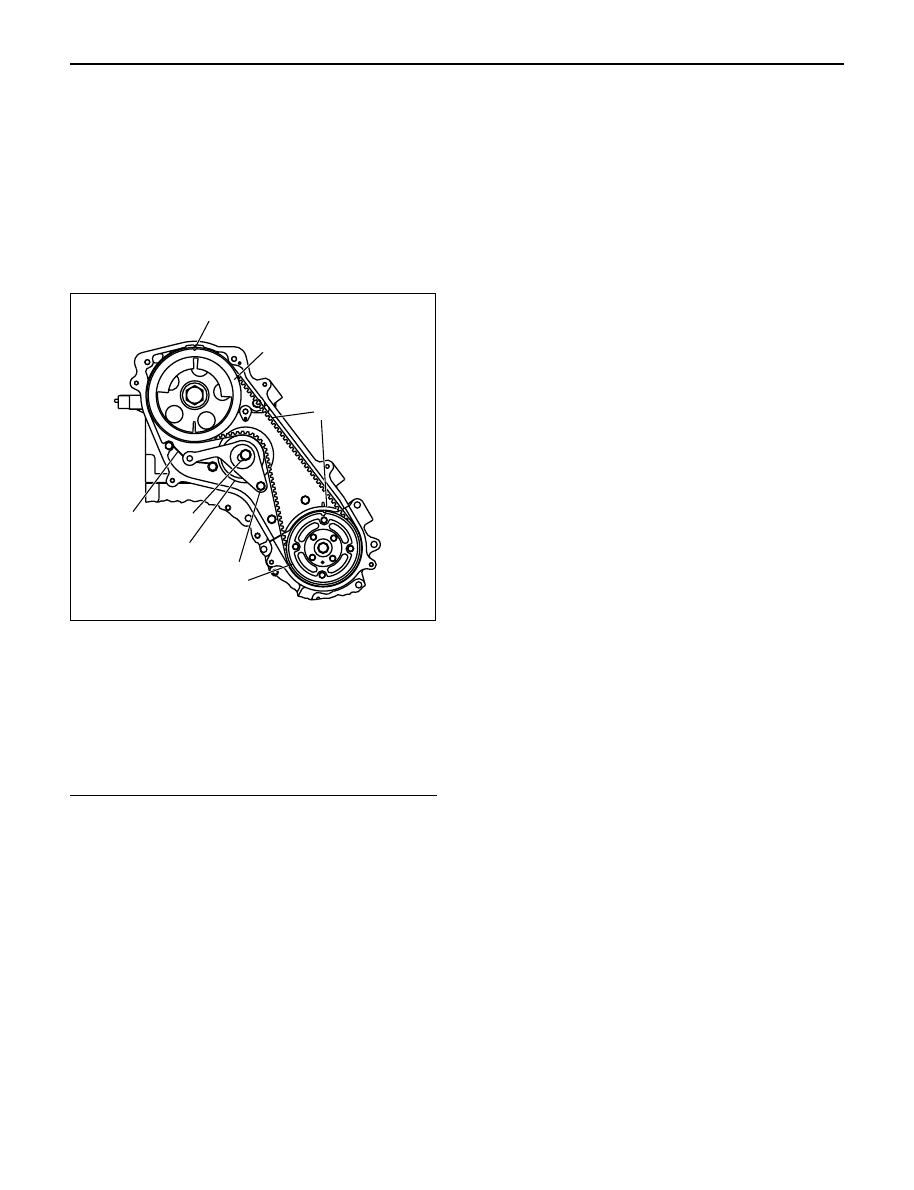

Legend

(1) Align Mark

(2) Camshaft Pulley

(3) Timing Belt

(4) High Pressure Oil Pump Pulley

(5) Tensioner Bolt B

(6) Tensioner Assembly

(7) Tensioner Bolt A

(8) Tensioner Spring

9. Install CMP sensor bracket.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

10. Connect CMP sensor cable.

11. Install timing belt cover.

Torque: 9 N·m (0.9 kg·m/78 lb in)

12. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

13. Immediately install high pressure oil pipe and

tighten to specified torque.

NOTE:

1) Use new O-ring.

2) Clean O-ring groove and fitting surface of parts.

3) Apply engine oil to O-ring.

Torque: 78 N·m (8.0 kg·m/58 lb ft)

14. Install the crankshaft damper pulley with specified

torque.

Torque: 216 N·m (22 kg·m/159 lb ft)

15. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

16. Install air cleaner cover and air duct.

1

2

3

8

6

7

4

5

F06R200006