Content .. 2331 2332 2333 2334 ..

Opel Frontera UBS. Manual - part 2333

6E–368

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

If connections and wiring are OK and DTC P1154

continues to set, replace the Bank 2 HO2S 1.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. A condition that affects other heated oxygen sensors

indicates probable contamination. To avoid

damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.

5. This step checks for conditions which may cause the

heated oxygen sensor to appear faulty. Correct any

of the described conditions if present.

8. To avoid damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.

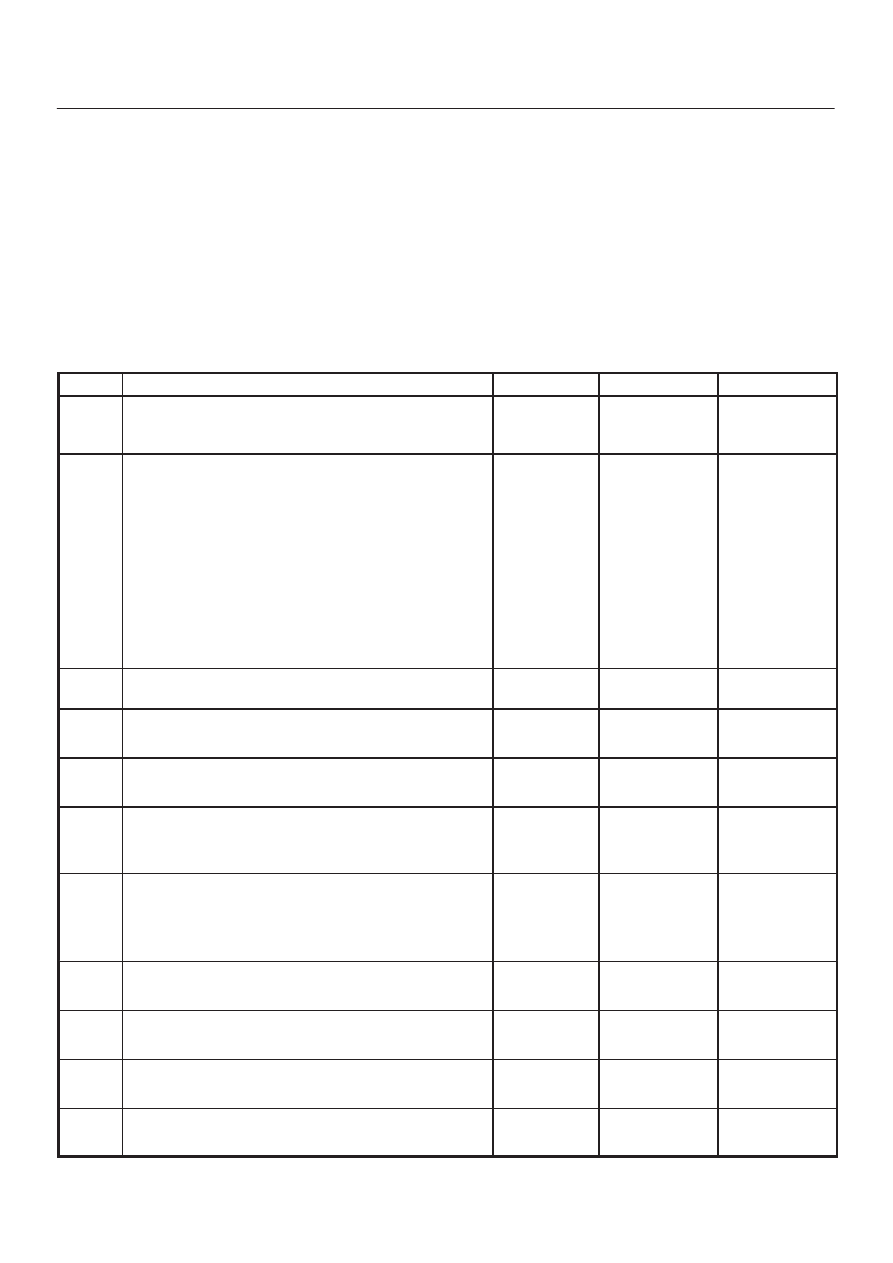

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

IMPORTANT: If any other DTCs are set (except P1133

and/or P1134), refer to those DTCs before proceeding

with this diagnostic chart.

1. Idle the engine at operating temperature.

2. Operate the vehicle within parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

3. Using a Tech 2, monitor “DTC” info for DTC P1154

until the DTC P1154 test runs.

Note the test result.

Does Tech 2 indicate DTC failed this ignition?

—

Go to

Step 3

Check the

Procedure

Refer to

Diagnostic

Aids

3

Did the Tech 2 also indicate P1133, and/or P1134 test

failed?

—

Go to

Step 17

Go to

Step 4

4

Check for leaks at the exhaust pipe joints.

Are the joints leaking?

—

Go to

Step 5

Go to

Step 6

5

Tighten the U-bolt nuts at the leaking joints.

Is your action complete?

—

Go to

Step 2

—

6

Check for gaskets that are damaged or improperly

installed.

Are there damaged or misaligned gaskets?

—

Go to

Step 7

Go to

Step 8

7

1. Replace the damaged gaskets.

2. Align the connections.

3. Tighten the connections.

Is your action complete?

—

Go to

Step 2

—

8

Check for loose exhaust flange connections.

Are the flange connections loose?

—

Go to

Step 9

Go to

Step 10

9

Tighten the stud nuts or bolts to specifications.

Is your action complete?

—

Go to

Step 2

—

10

Check for burned or corroded exhaust pipes.

Are the exhaust pipes burned or corroded?

—

Go to

Step 11

Go to

Step 12

11

Replace the exhaust pipes, as required.

Is your action complete?

—

Go to

Step 2

—