Content .. 2249 2250 2251 2252 ..

Opel Frontera UBS. Manual - part 2251

6E–40

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

D

Updates the Fail Record each time the diagnostic

test fails

IMPORTANT:

Only four Fail Records can be stored.

Each Fail Record is for a different DTC. It is possible that

there will not be Fail Records for every DTC if multiple

DTCs are set.

Special Cases of Type B Diagnostic Tests

Unique to the misfire diagnostic, the Diagnostic Executive

has the capability of alerting the vehicle operator to

potentially damaging levels of misfire. If a misfire

condition exists that could potentially damage the

catalytic converter as a result of high misfire levels, the

Diagnostic Executive will command the MIL to “flash” at a

rate of once per second during those the time that the

catalyst damaging misfire condition is present.

Fuel trim and misfire are special cases of

Type B

diagnostics. Each time a fuel trim or misfire malfunction is

detected, engine load, engine speed, and engine coolant

temperature are recorded.

When the ignition is turned off, the last reported set of

conditions remain stored. During subsequent ignition

cycles, the stored conditions are used as reference for

similar conditions. If a malfunction occurs during two

consecutive trips, the Diagnostic Executive treats the

failure as a normal

Type B diagnostic, and does not use

the stored conditions. However, if a malfunction occurs

on two non-consecutive trips, the stored conditions are

compared with the current conditions. The MIL will then

illuminate under the following conditions:

D

When the engine load conditions are within 10% of

the previous test that failed.

D

Engine speed is within 375 rpm, of the previous test

that failed.

D

Engine coolant temperature is in the same range as

the previous test that failed.

Storing and Erasing Freeze Frame Data and Failure

Records

Government regulations require that engine operating

conditions be captured whenever the MIL is illuminated.

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Freeze Frame data can only be overwritten with data

associated with a misfire or fuel trim malfunction. Data

from these faults take precedence over data associated

with any other fault. The Freeze Frame data will not be

erased unless the associated history DTC is cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

D

Air Fuel Ratio

D

Air Flow Rate

D

Fuel Trim

D

Engine Speed

D

Engine Load

D

Engine Coolant Temperature

D

Vehicle Speed

D

TP Angle

D

AP Angle

D

MAP/BARO

D

Injector Base Pulse Width

D

Loop Status

Intermittent Malfunction Indicator Lamp

In the case of an “intermittent” fault, the MIL (“Check

Engine” lamp) may illuminate and then (after three trips)

go “OFF”. However, the corresponding diagnostic trouble

code will be stored in memory. When unexpected

diagnostic trouble codes appear, check for an intermittent

malfunction.

A diagnostic trouble code may reset. Consult the

“Diagnostic Aids” associated with the diagnostic trouble

code. A physical inspection of the applicable sub-system

most often will resolve the problem.

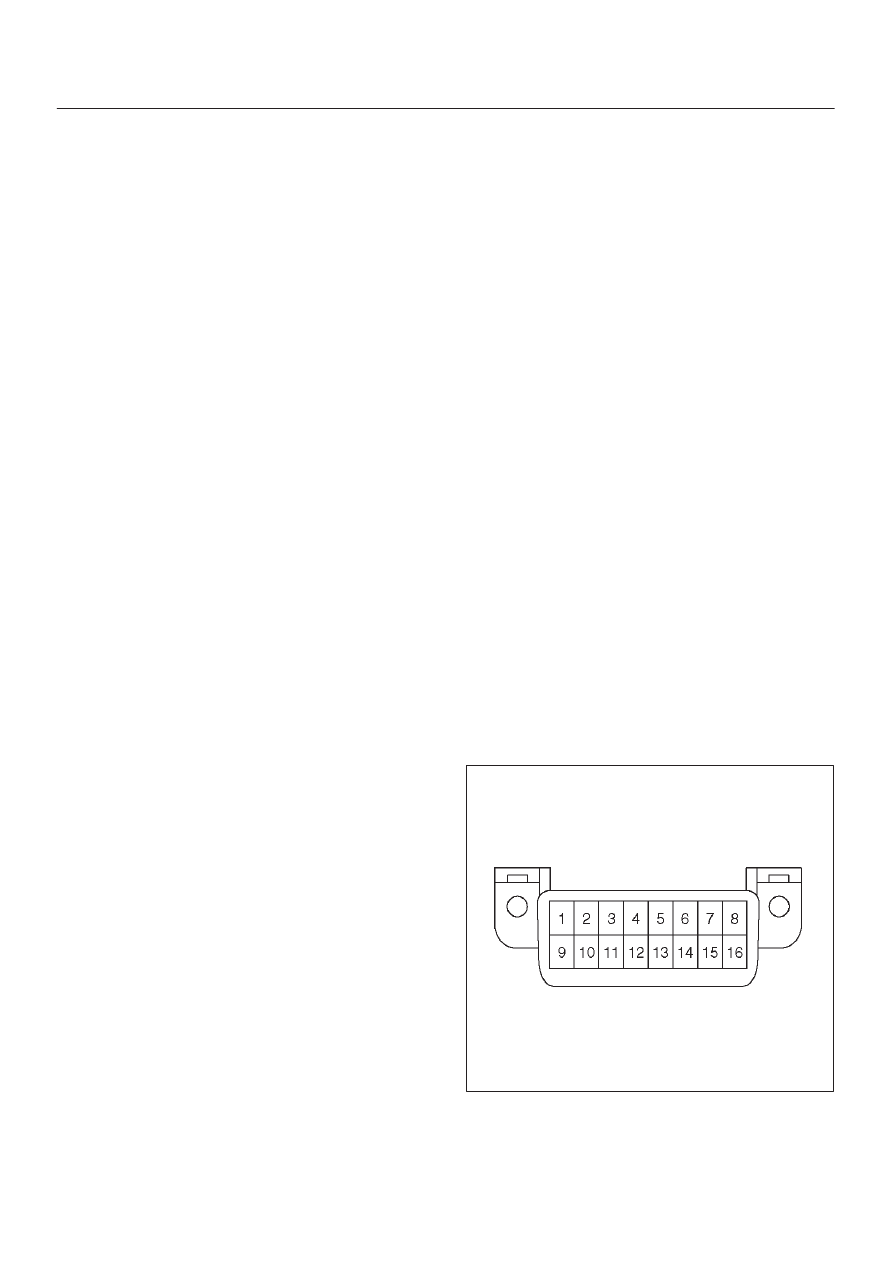

Data Link Connector (DLC)

The provision for communication with the control module

is the Data Link Connector (DLC). It is located at the

lower left of the instrument panel behind a small square

cover. The DLC is used to connect to the Tech 2 Scan

Tool. Some common uses of the Tech 2 are listed below:

D

Identifying stored Diagnostic Trouble Codes (DTCs).

D

Clearing DTCs.

D

Performing output control tests.

D

Reading serial data.

TS24064