Content .. 2143 2144 2145 2146 ..

Opel Frontera UBS. Manual - part 2145

6E–153

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0152 – HO2S Circuit High Voltage Bank 2 Sensor 1

(Cont'd)

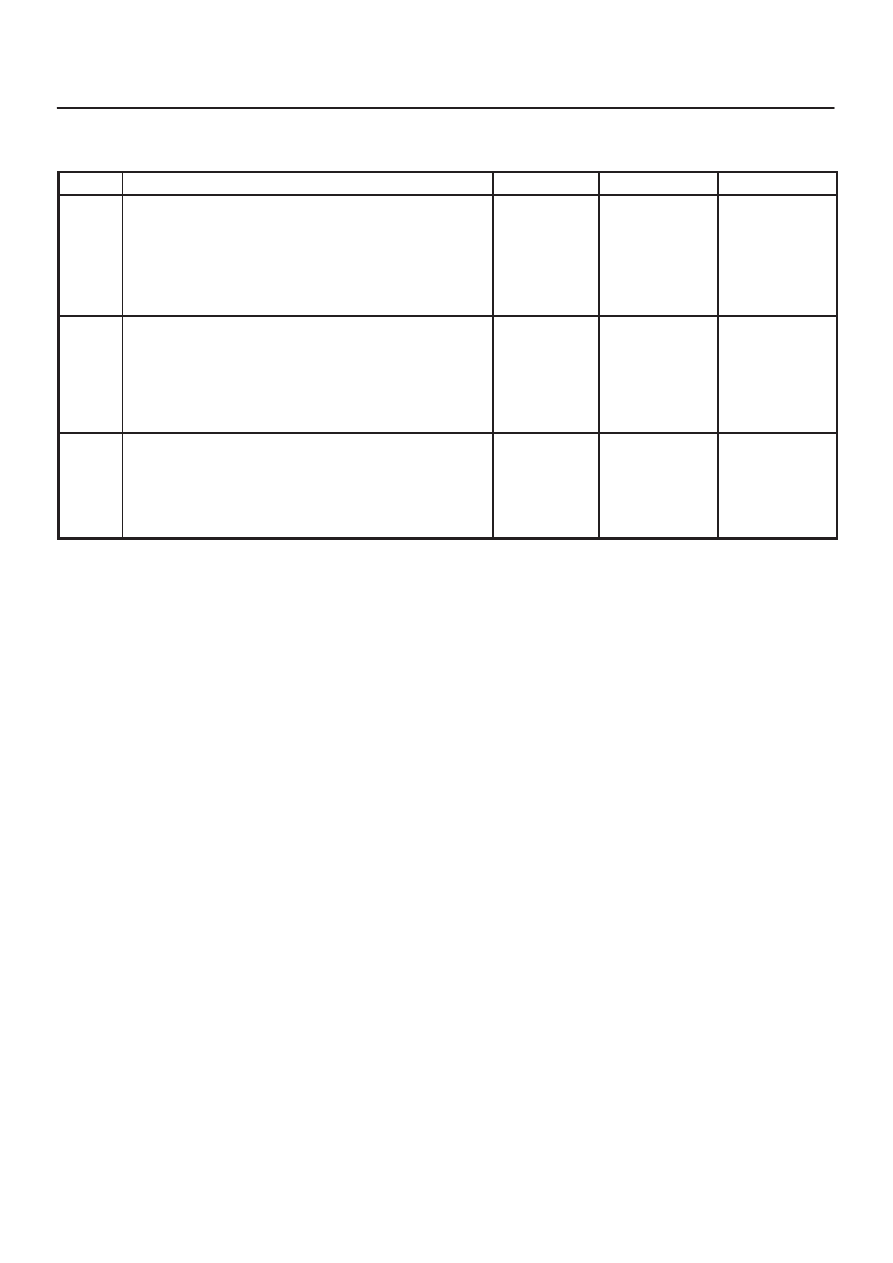

Step

No

Yes

Value(s)

Action

6

1. Ignition “ON,” engine“OFF.”

2. At Bank 2 HO2S 1 connector (PCM side) jumper

both the HO2S high and low signal circuits (PCM

side) to ground.

3. Using Tech 2, monitor Bank 2 HO2S 1 voltage.

Is Bank 2 HO2S 1 voltage below the specified value?

10 mV

Go to

Step 7

Go to

Step 8

7

1. Disconnect the jumpers to ground from Bank 2

HO2S 1 PCM-side connector.

2. With the HO2S 1 connector disconnected, monitor

Bank 2 HO2S 1 voltage.

Is the Bank 2 HO2S 1 voltage between the specified

values?

425-475 mV

Refer to

Diagnostic

Aids

Go to

Step 8

8

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?

—

Verify repair

—