Content .. 1949 1950 1951 1952 ..

Opel Frontera UBS. Manual - part 1951

DIFFERENTIAL (REAR 244mm) 4A2B–27

2. Adjust the backlash between the side gear and

the pinion gear.

Backlash: 0.15 – 0.20 mm (0.006 – 0.008 in)

Thickness of thrust washers available

mm

0.80

0.90

1.00

1.10

1.20

1.30

in

0.031

0.035

0.039

0.043

0.047

0.051

425RY00008

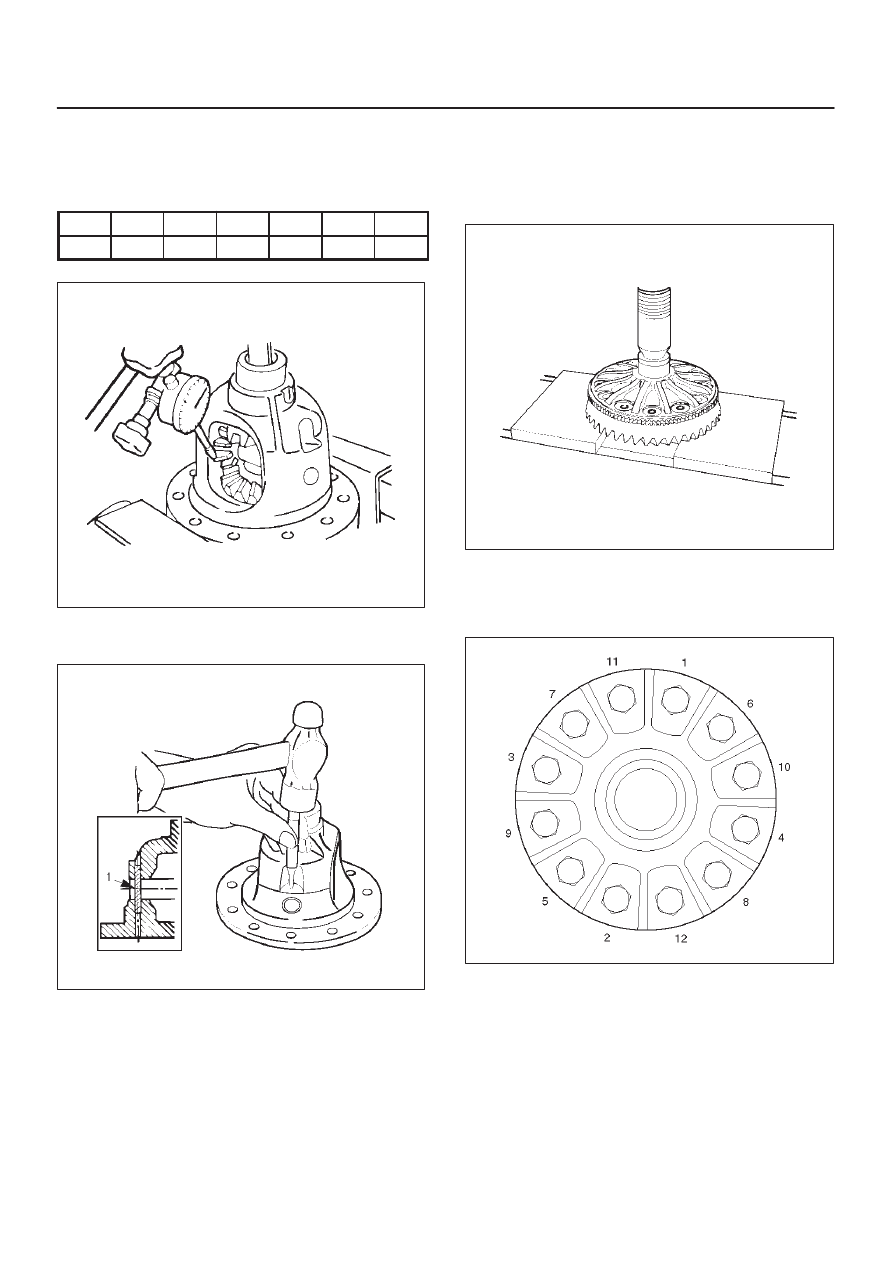

4. Install lock pin.

D

Install the lock pin using small drift.

425RY00009

5. Install exciter ring (If equipped with rear wheel

antilock).

D

Press the exciter ring on the differential cage using

the ring gear as a pilot.

NOTE: Discard used exciter ring and install new one.

425RS052

6. Tighten the bolts in diagonal sequence as illustrated.

Torque: 127N·m (13.0kg·m/94 lb ft)

NOTE: Discard used bolts and install new ones.

425RW033