Content .. 1419 1420 1421 1422 ..

Opel Frontera UBS. Manual - part 1421

7A–18

AUTOMATIC TRANSMISSION (4L30–E)

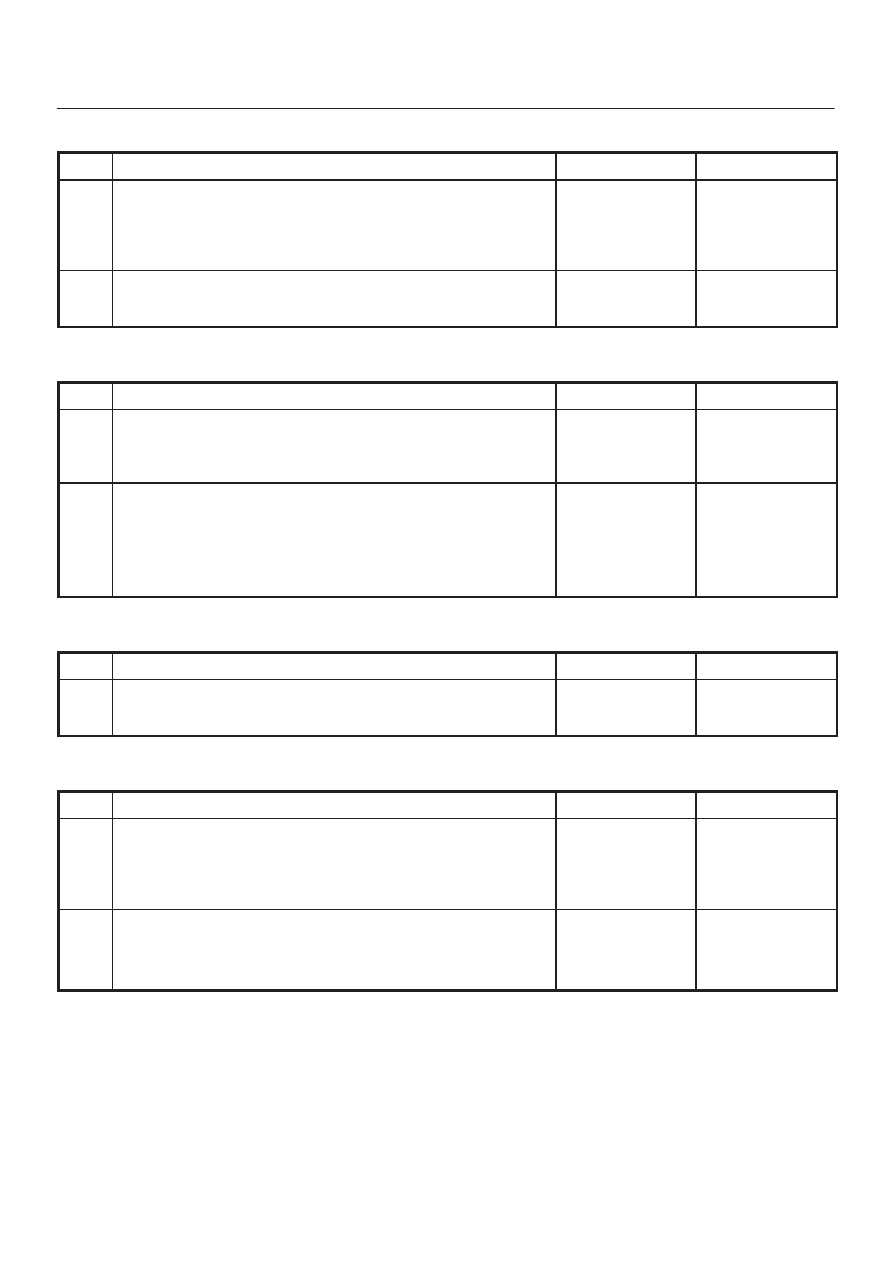

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2 Downshift

Step

Action

Yes

No

1

Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes

of High Line

Pressure in this

section

2

Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Chart 10: Intermittent 4TH TO 2ND Gear Downshift At Steady Speed

Step

Action

Yes

No

1

Check for consistent speed sensor reading with scan tool.

Was the reading correct?

Replace mode

switch for

intermittent

contact.

Go to Step 2

2

1. Check for wiring harness damage or short to ground. If OK, go

to (2).

2. Check transmission speed sensor connections. If OK, go to

(3).

3. Replace transmission speed sensor.

Was the replacement complete?

—

Replace speed

sensor.

Chart 11: Engine Flare At Shifting During Turning Only (Usually With Warm Engine)

Step

Action

Yes

No

1

Check for oil leaks at transmission.

Was the problem found?

Replace

transmission oil

filter and gasket

—

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

Step

Action

Yes

No

1

Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

2

1. Check for a stuck 1–2 accumulator valve (320).

2. Check for servo piston (106) leaks.

3. Check for a stuck band apply solenoid (323).

Was line pressure normal?

Repair or replace

—