Content .. 1348 1349 1350 1351 ..

Opel Frontera UBS. Manual - part 1350

6D – 20 ENGINE ELECTRICAL

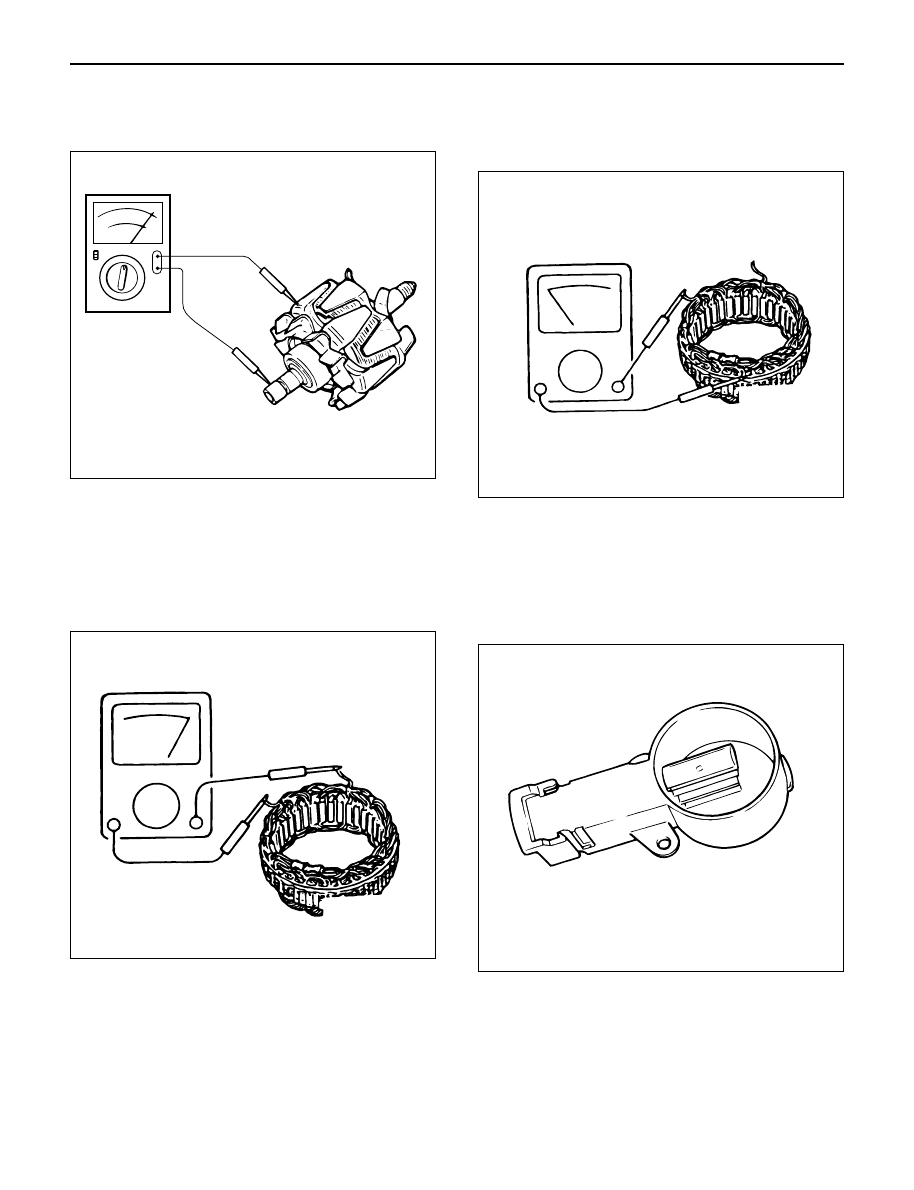

4. Check for continuity between slip ring and rotor

core.

In case of continuity, replace the rotor assembly.

Stator Coil

1. Check for continuity across the stator coils. If no

continuity exists, replace the coils.

Resistance value at 20°C

Standard: Approx 0.07

Ω

2. Check for continuity across one of the stator coils

and stator core. If a continuity exists, replace the

coil.

Standard: More than 1M

Ω

Brush

Measure the brush length.

If more than limit, replace the brush.

Standard: 18.0 mm (0.709 in)

Limit: 5.5 mm (0.217 in)

+

−

066RS017

066RS035

066RW024

066RS034