Content .. 1330 1331 1332 1333 ..

Opel Frontera UBS. Manual - part 1332

6A – 78 ENGINE MECHANICAL

2) Apply liquid gasket (TB1207B or equivalent)

between the cylinder block and the crankcase

fitting surfaces.

3) Install the timing gear case to the cylinder body.

4) Tighten the timing gear case bolt together with

the timing gear case gasket to the specified

torque.

Torque: 20 N·m (2.0 kg·m/14.5 lb·ft)

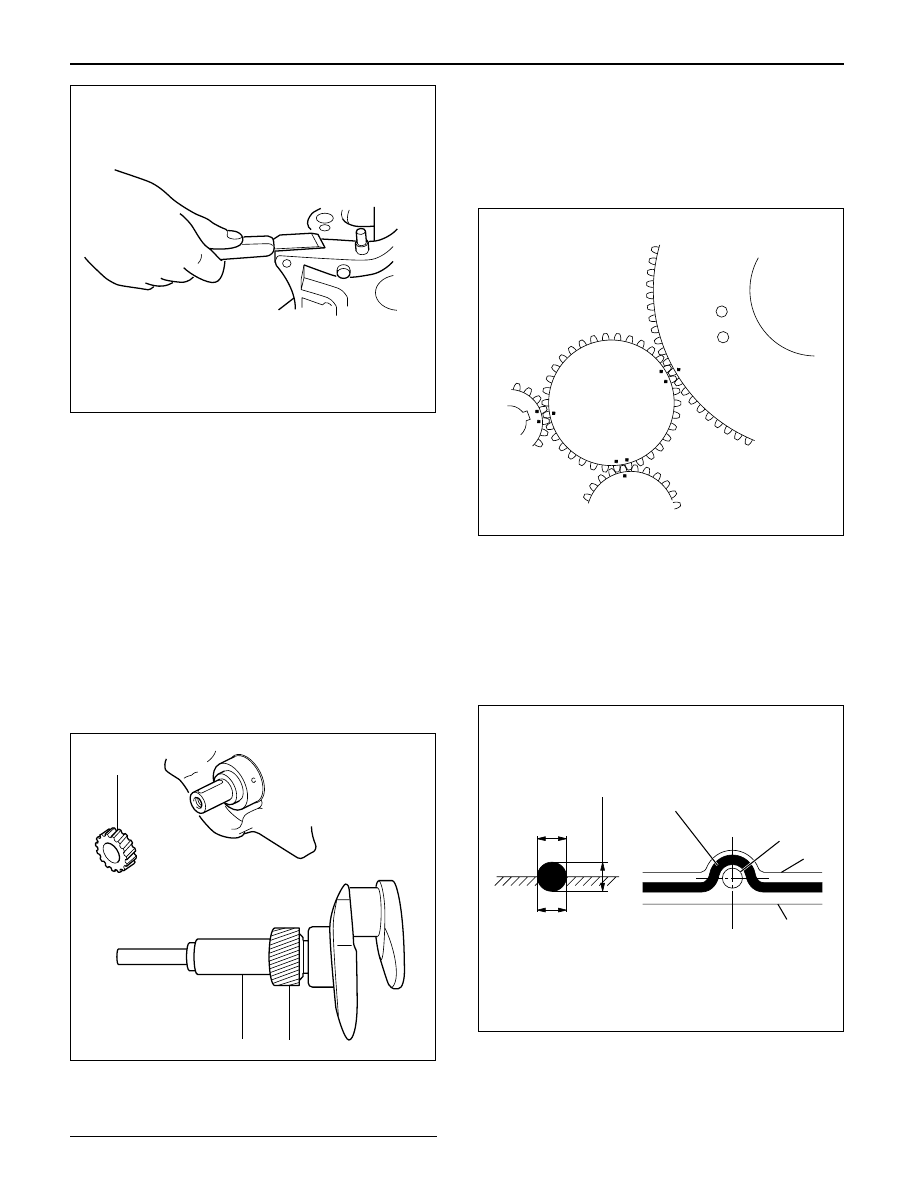

12. Crankshaft Gear

1) Set key to crankshaft key groove.

2) The timing mark on the crankshaft gear must be

facing outward.

3) Use the crankshaft gear installer to install the

crankshaft gear.

Crankshaft installer: 9-8522-0021-0

Legend

(1) Crankshaft Gear Installer

(2) Crankshaft Gear

13. Installation of the Timing Gear

1) Align teeth on the scissors gear and lock them

before install timing gear.

2) Align timing marks on each timing gear and

assemble them.

3) Refer to timing gear detail in this manual.

14. Timing Gear Case Cover

1) Remove lock bolt from idle gear A and remove

lock pin from idle gear C.

2) Install oil pump gear oil seal before assembling

timing gear case cover.

3) Clean fitting surface and apply liquid gasket

(TB1207C or equivalent) to fitting surface.

4) Tighten bolts to specified torque.

Torque: 20 N·m (2.0 kg·m/14.5 lb ft)

1

2

2

012RW066

2

2~2.5mm

2~2.5mm

Apply liquid gasket around inside

of the bolt hole

Bolt hole

Inside

Outside

F06HX00001

012RW024

012RW064