Content .. 1312 1313 1314 1315 ..

Opel Frontera UBS. Manual - part 1314

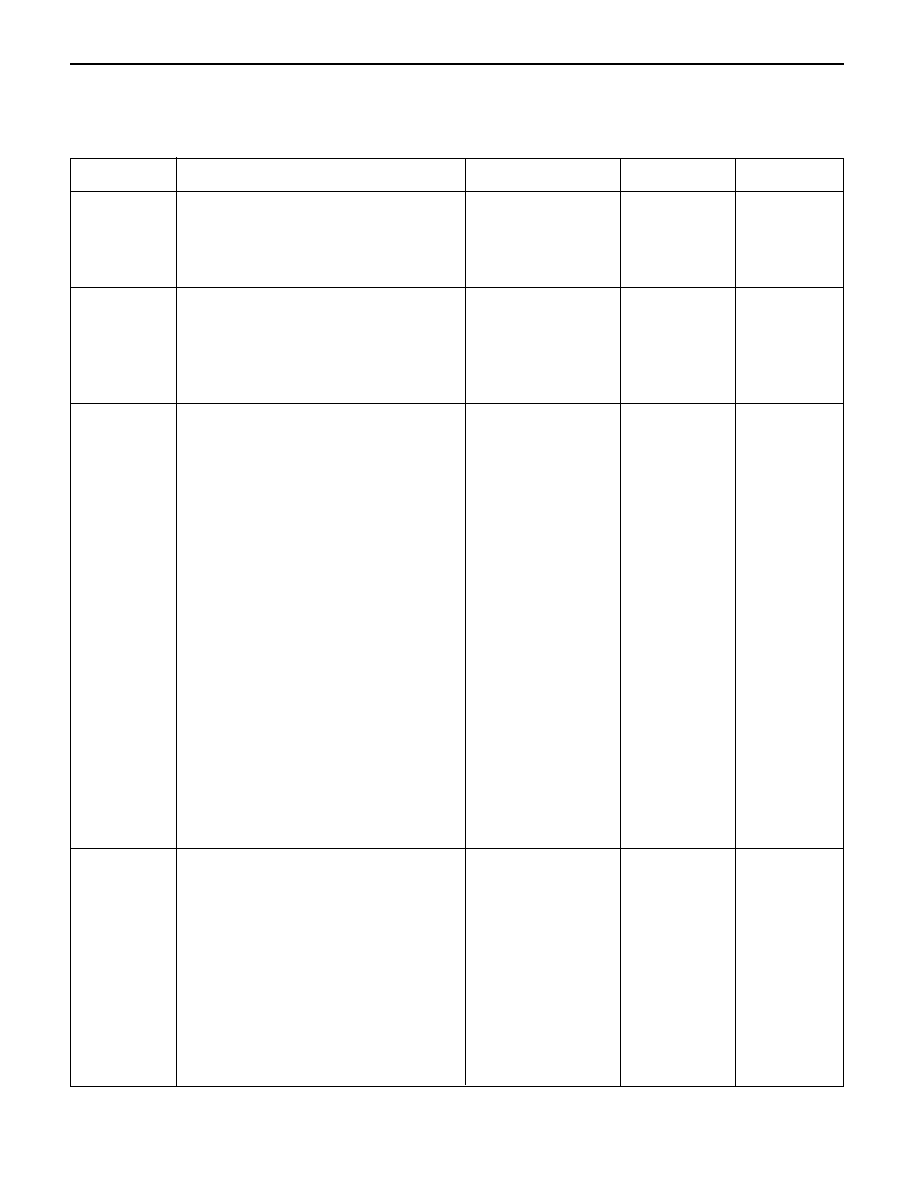

6A – 6 ENGINE MECHANICAL

SERVICE STANDARD

Engine

mm (in)

Parts

Items

Service standard

Service limit

Remarks

Cylinder Head

Valve Spring

Valve and

Valve guide

Camshaft

0.075 (0.0030) or less

95.0 (3.740)

45.7 (1.8)

—

241 (54.2)

6.959 – 6.977

(0.27 – 0.272)

6.692 – 6.970

(0.271 – 0.272)

0.023 – 0.056

(0.0009 – 0.0022)

0.03 – 0.063

(0.0011 – 0.0024)

8.0 (0.312)

1.1 (0.0433)

1.2 (0.0472)

1.2 (0.0472)

45°

2.1 (0.0827)

2.1 (0.0827)

0.08 (0.00314)

46.67 (1.8374)

46.77 (1.8413)

29.939 – 29.960

(1.167 – 1.168)

0.02 (0.0008) or less

0.40 – 0.082

(0.0016 – 0.0032)

0.50 (0.0197)

—

44.8 (1.765)

1.6 (0.063)

210 (47.22)

6.92 (0.270)

6.90 (0.269)

0.19 (0.0074)

0.20 (0.0079)

—

1.6 (0.0630)

1.1 (0.0433)

1.1 (0.0433)

—

2.6 (0.1024)

2.6 (0.1024)

2.0 (0.00797)

46.57 (1.8335)

46.67 (1.8374)

29.84 (1.1748)

0.10 (0.0039)

0.12 (0.0047)

Cannot be

reground

Cylinder head lower surface for flatness

Cylinder head height

Free height

Squareness

Spring tension (when assembled)

N(lb)

Diameter of Valve stem

IN

EX

Valve and valve guide clearance

IN

EX

Valve guide upper end height

(Measured from the Cylinder head upper

face)

Valve guide margin

Valve thickness

IN

EX

Valve seat contact surface angle

Valve seat contact width

IN

EX

End play

Cam lobe height

IN

EX

Journal diameter

Runout

Camshaft oil clearance