Content .. 1296 1297 1298 1299 ..

Opel Frontera UBS. Manual - part 1298

FUEL SYSTEM 6C – 9

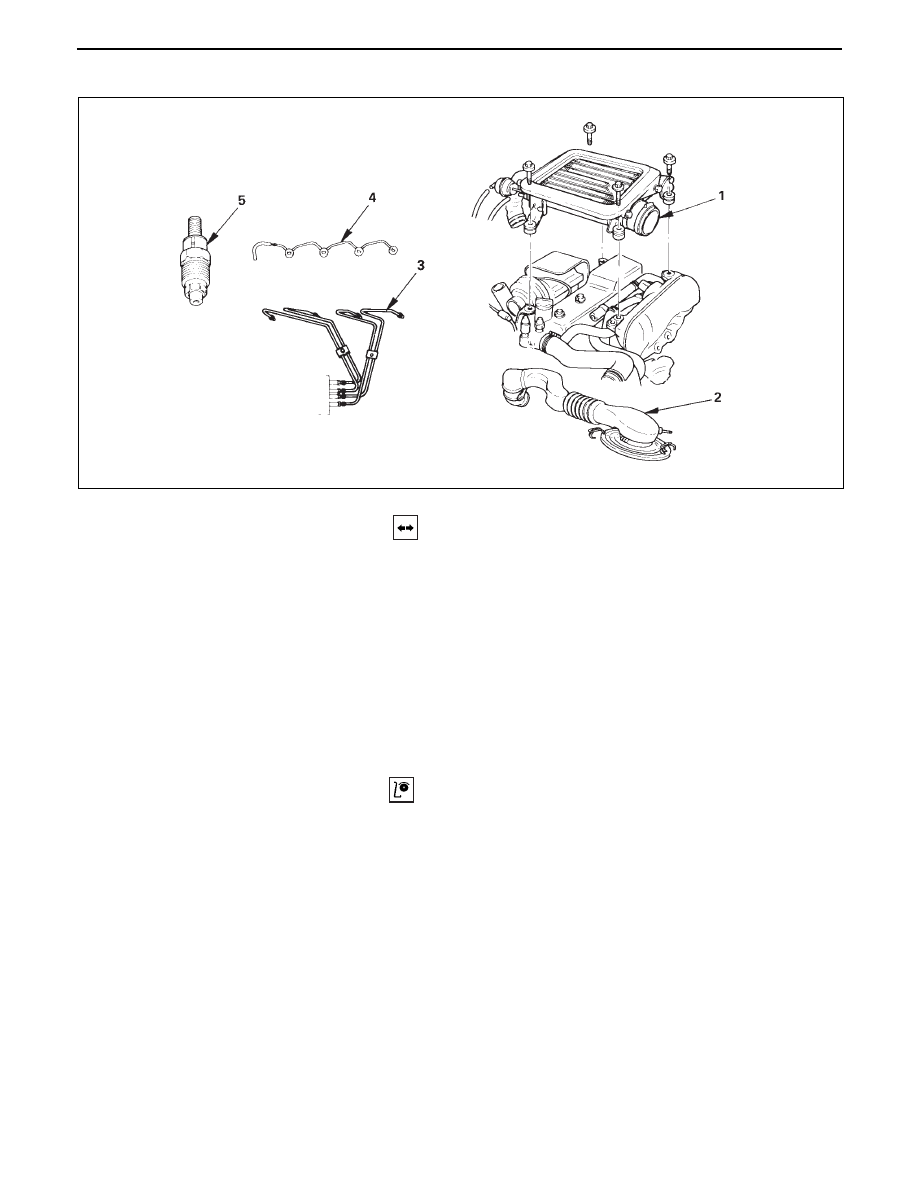

INJECTION NOZZLE

REMOVAL

Preparation:

•

Disconnect battery ground cable.

1.

Intercooler Assembly (4JG2-T Only)

•

(Refer to intercooler removal steps in section 6A2)

2.

Air Cleaner Cover & Air Duct

3.

Injection Pipe

•

Release injection pipe clip.

•

Loosen the flare nut on the injection pump side.

•

Loosen the flare nut on the injection nozzle side,

disconnect and put aside the pipe.

4.

Leak Off Pipe

5.

Injection Nozzle

INSPECTION

•

Set the nozzle in a nozzle tester.

Check there is no fuel leak in the nozzle seal when

a fuel pressure of 14710 kpa (150kg/cm

2

/2133 psi) is

applied.

If there is leak, replace.