Content .. 1204 1205 1206 1207 ..

Opel Frontera UBS. Manual - part 1206

6E–190

ENGINE DRIVEABILITY AND EMISSIONS

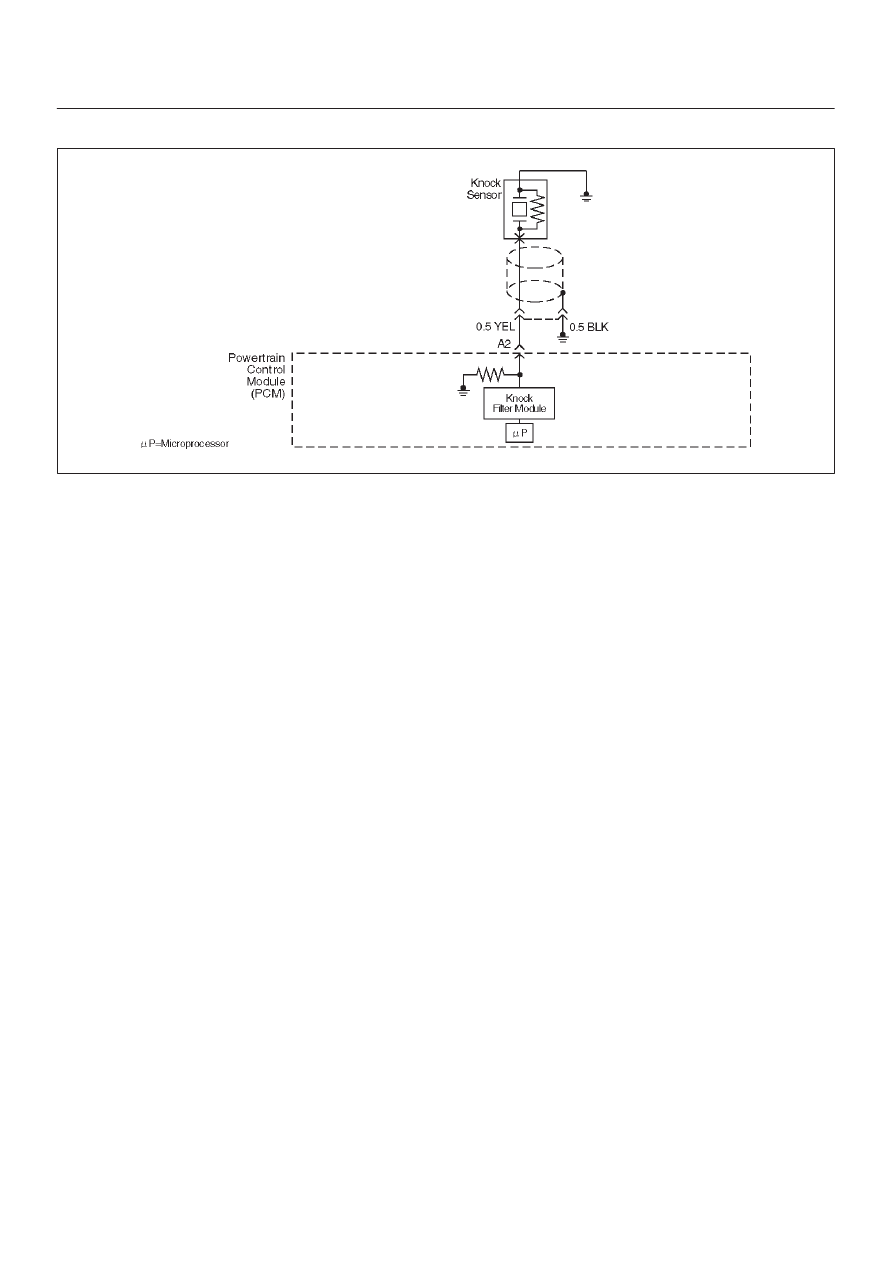

Diagnostic Trouble Code (DTC) P0327 KS Sensor Circuit

D06RW035

Circuit Description

The powertrain control module (PCM) uses the knock

sensor to detect engine detonation, allowing the PCM to

retard ignition control (IC) spark timing based on the

knock sensor (KS) signal being received. The knock

sensor produces an AC signal so that under a no knock

condition the signal on the KS circuit measures about

0.007 V AC. The signal amplitude and frequency are

dependent upon the amount of knock being experienced.

The PCM monitors the KS signal and can diagnose the

KS sensor and circuitry.

Conditions for Setting the DTC

D

Engine running for at least 10 seconds.

D

The TP sensor is greater than 5%.

D

The ECT sensor is greater than 60

°

C (140

°

F).

D

Engine speed is between 2000 and 4000 RPM.

D

The knock sensor signal voltage is less than 0.20 volts,

or greater than 4.8 volts.

D

All conditions are present for more than 15 seconds.

Action Taken When the DTC Sets

D

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

D

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

D

The PCM will use a calculated spark retard value to

minimize knock during conditions when knock is likely

to occur. The calculated value will vary based on

engine speed and load.

Conditions for Clearing the MIL/DTC

D

DTC P0327 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Ensures that the fault is present.

4. The knock sensor is attached to a short jumper

harness, so it can be tested without removing the

intake manifold. A 2-wire connector for the knock

sensor is accessible behind the left rear fuel injector.