Content .. 1177 1178 1179 1180 ..

Opel Frontera UBS. Manual - part 1179

6E–82

ENGINE DRIVEABILITY AND EMISSIONS

Engine Cranks But Will Not Run

(Cont'd)

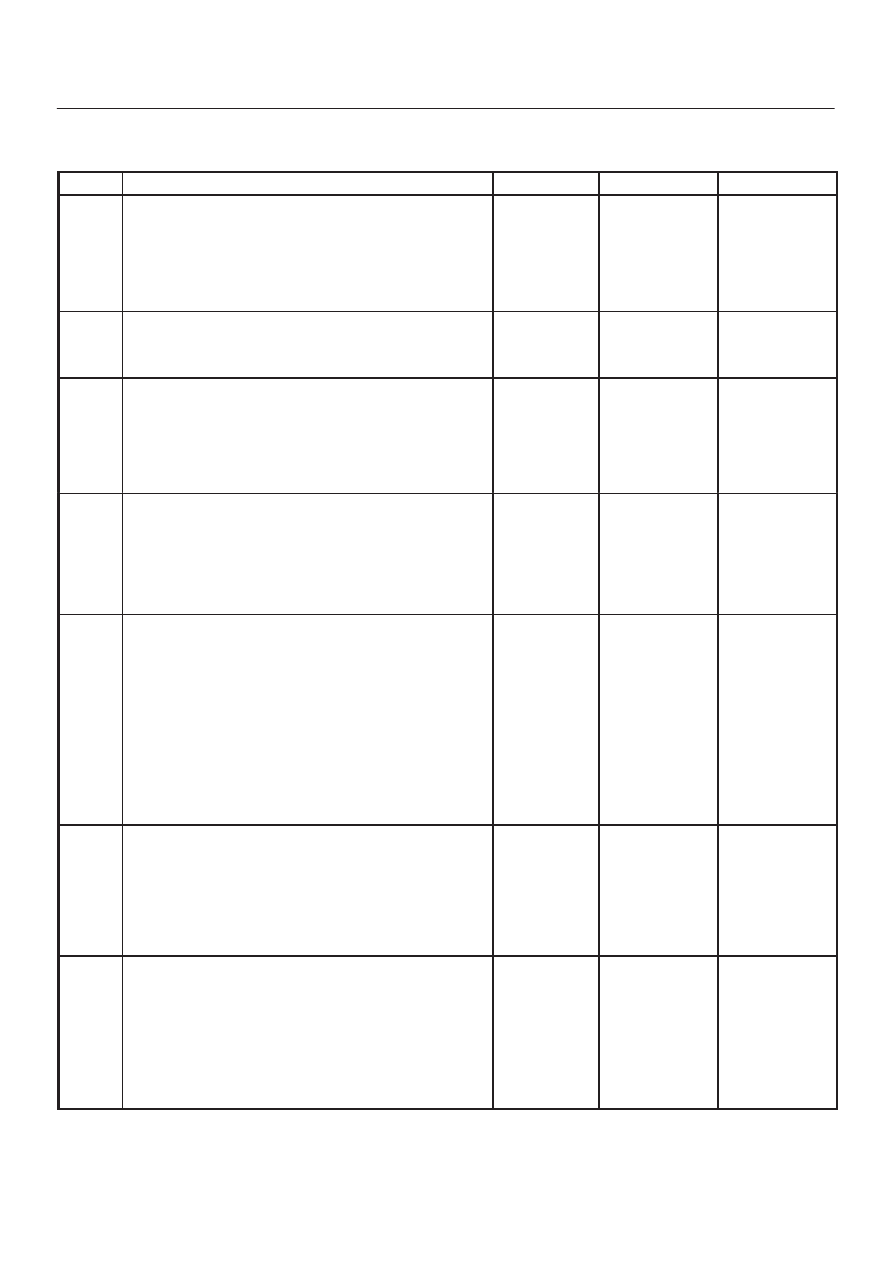

Step

No

Yes

Value(s)

Action

13

1. Remove any ignition coil and install a spark tester at

the spark plug end of the coil.

2. Observe the tester while the engine is cranking.

Was a crisp, blue spark observed? Only one or two

sparks followed by no result is considered the same as

“No Spark.”

—

Go to

Step 15

Go to

Step 14

14

Replace the ignition coil, and return to Step 13 to test

the remaining coils.

Is the action complete?

—

Verify repair

—

15

Repeat Step 13 for each coil. Remove only one coil at a

time, and reinstall each coil on its spark plug after

testing, but do not refasten coils with screws at this

time.

After all coils have passed the spark test, does the

engine start?

—

Refasten all

coils with

their screws

Go to

Step 16

16

1. Remove the spark plugs from all cylinders.

2. Visually inspect the spark plug electrodes.

3. Replace any spark plugs with loose or missing

electrodes or cracked insulators.

Did your inspection reveal any spark plugs exhibiting

excessive fouling?

—

Correct the

fouling

condition

Go to

Step 17

17

Refer to

Engine Mechanical Diagnosis to diagnose the

following conditions:

D

Faulty or incorrect camshaft drive belts

D

Leaking or sticky valves or rings

D

Excessive valve deposits

D

Loose or worn rocker arms

D

Weak valve springs

D

Incorrect valve timing

D

Leaking head gasket

Is the action complete?

—

Verify repair

Go to

Step 19

18

Observe the “Engine Speed” data display on the scan

tool while cranking the engine.

Is the engine RPM indicated? (If the scan tool is

normally powered from the cigarette lighter socket, and

if the scan tool display goes blank while cranking the

engine, it will be necessary to power the scan tool

directly from the vehicle battery.)

—

Go to

Step 19

Go to

Step 28

19

1. Disconnect the 7-pin gray connector at the rear of

the air filter beneath the point where the air duct

attaches to the MAF sensor.

2. Ignition “ON.”

3. Using a test light connected to ground, probe the

ignition terminal at the PCM (female) side of the

7-pin connector.

Is the test light “ON?”

—

Go to

Step 20

Go to

Step 26