Content .. 1011 1012 1013 1014 ..

Opel Frontera UBS. Manual - part 1013

4B1–30DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Front Axle Diagnosis

D

When the 4WD switch is operated from 4H to 2H,

indicator light does not go out.

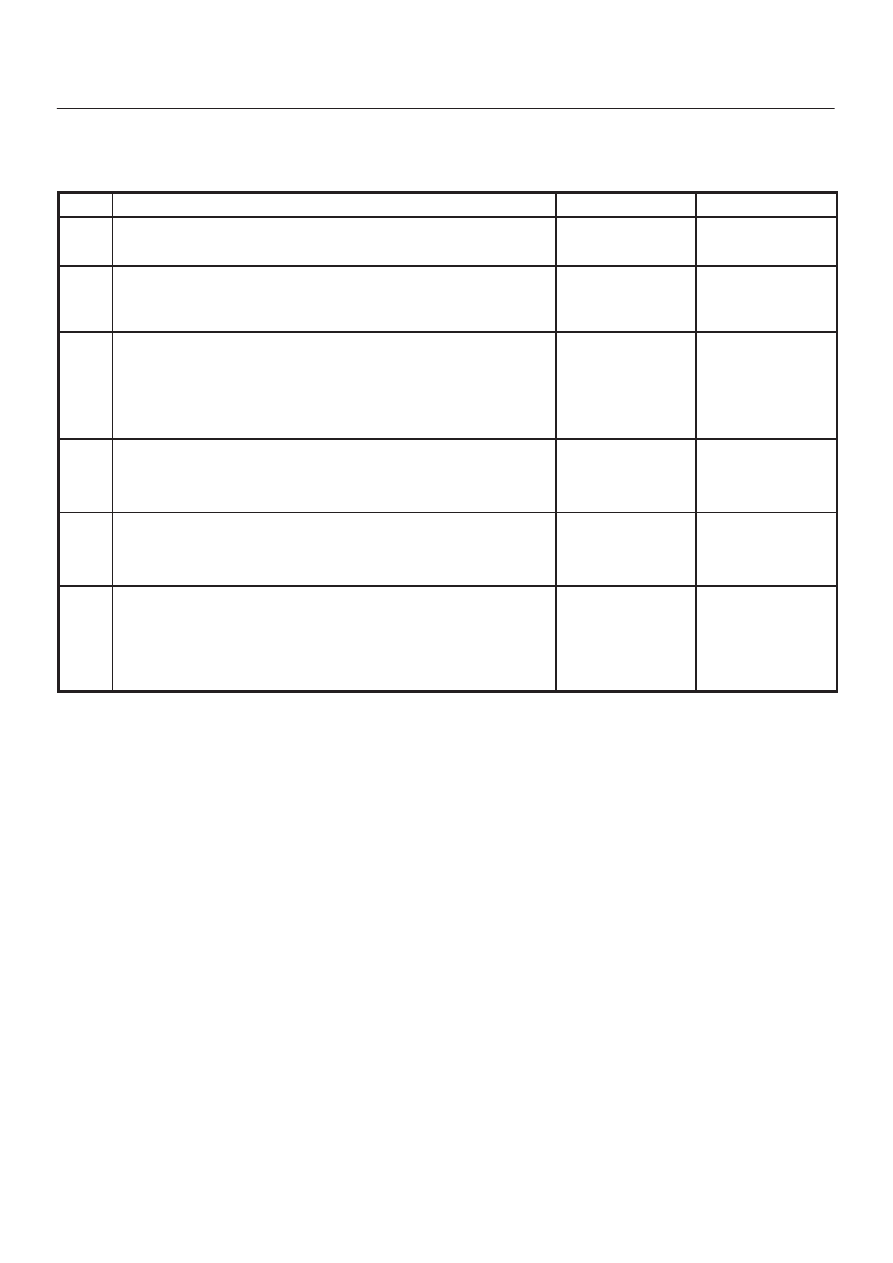

Step

Action

Yes

No

1

Drive slow 100 — 200m after a few minutes” idling.

Has indicator light gone out?

All right.

Go to Step 2

2

Jack up front tires.

Does the right side of front wheel rotate when the left side of front

wheel is rotated?

Go to Step 4

Go to Step 3

3

1. Check the actuator switch.

2. Check the circuit to indicator.

Was a problem found?

Trace this chart

from the start

after repair or

replace.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.

4

1. Check the VSV valve.

2. Check the circuit to VSV valve.

Was a problem found?

Trace this chart

from the start

after repair or

replace.

Go to Step 5

5

Is vacuum piping all right? (tank, hose, & pipe damage or trouble)

Go to Step 6

Trace this chart

from the start

after repair or

replace.

6

Does actuator work all right?

Trace this chart

from the start.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.