Opel Frontera UBS. Manual - part 82

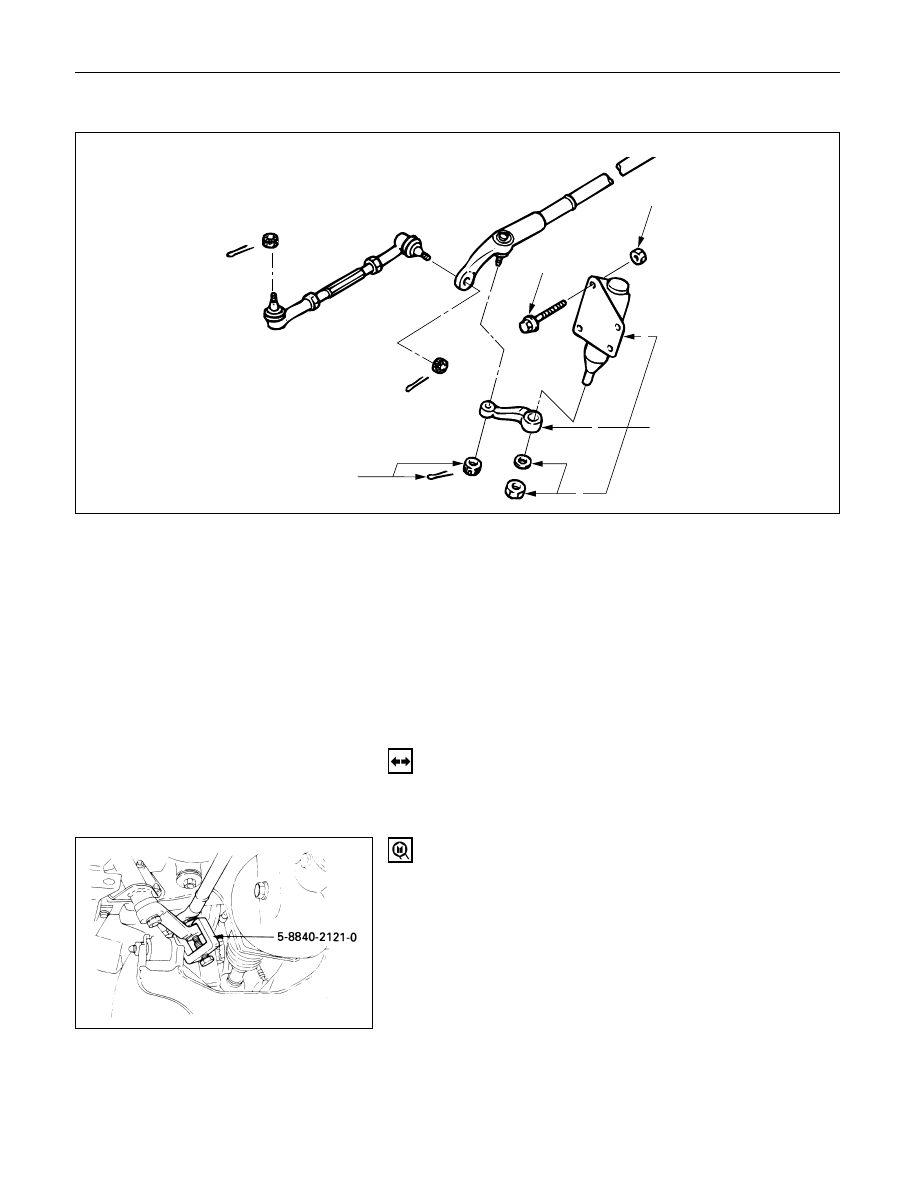

STEERING LINKAGE 2A – 49

RELAY LEVER

2

2

3

6

5

4

1

hese steps are based on the LHD model.

Removal Steps

1.

Nut and cotter pin

2.

Bolt and nut

3.

Relay lever and Bracket

4.

Nut and washer

5.

Relay lever

6.

Bracket

Installation Steps

6.

Bracket

5.

Relay lever

4.

Nut and washer

3.

Relay lever and bracket

2.

Bolt and nut

1.

Nut and cotter pin

REMOVAL

Preparation:

Raise the vehicle and support the frame with suitable

safety stands.

1. Nut and Cotter pin

Disconnect relay lever at the center track rod.

Remover: 5-8840-2121-0 (J-36831)

433RW005

These steps are based on the LHD model.