Opel Frontera UE. Manual - part 998

7A–16

AUTOMATIC TRANSMISSION (4L30–E)

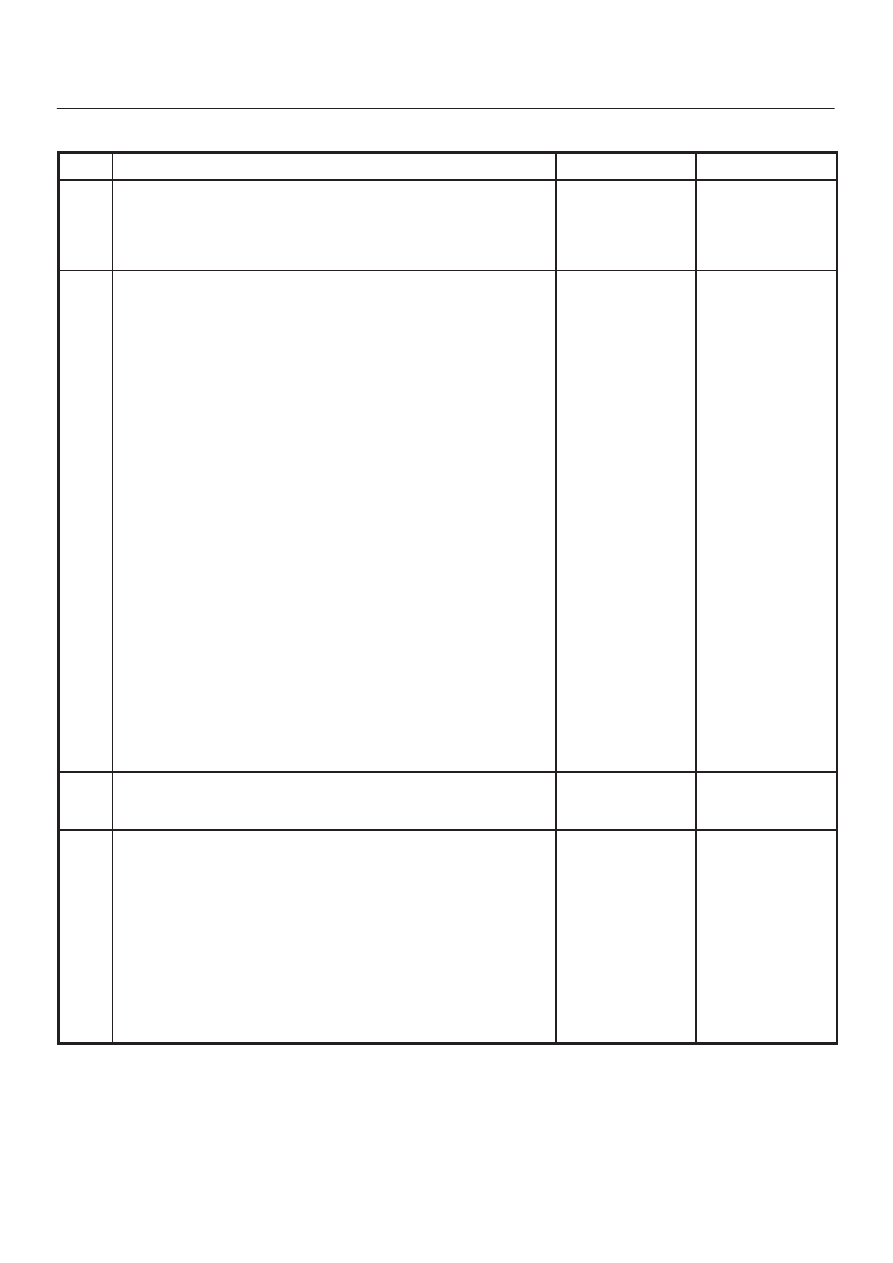

Chart 6: Diagnostic Trouble Code (DTC) P0730

Step

Action

Yes

No

1

Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes

of High Line

Pressure in this

section.

2

1. 1st and 2nd gear missing or 3rd and 4th gear missing.

Check appropriate shift valve. If OK replace solenoid.

2. No engine brake in any range (All ranges in Drive and Reverse

are OK)

Check for suspected conditions modifying delays to clutch

apply:

– Overrun clutch seal damaged.

– Excessive overrun clutch piston travel.

– Defective 3–4 accumulator piston.

– Causes of internal leaks.

– Causes of burned clutch plates.

3. 1st and 4th gear missing or 2nd and 3rd gear missing.

Shift solenoid A stuck. Replace shift solenoid A.

4. DTC P0730 is set in D range 1st gear above 3500 rpm.

Go to Step 3.

5. DTC P0730 is set in D range 3rd gear between 55-80 mph.

NOTE: Perform this test within safe and legal limits.

Check for suspected conditions modifying delays to clutch

apply:

– 4th clutch seal damaged.

– Excessive 4th clutch piston travel.

– Defective 3–4 accumulator piston.

– Causes of internal leaks.

– Causes of burned clutch plates.

Was the problem found?

Repair or replace

—

3

Check 3rd gear in “D” in winter mode.

Does vehicle move?

Shift solenoid A

stuck. Replace

shift solenoid A.

Go to Step 4

4

Check for suspected conditions modifying delays to clutch apply:

– 2nd clutch seal damaged.

– Excessive 2nd clutch piston travel.

– Defective accumulator piston.

– Causes of internal leaks.

– Check ball missing or out of location in 2nd clutch.

– Seals cut, damaged or missing.

– Gaskets defective.

– Causes of burned clutch plates.

Was the problem found?

Repair or replace

—