Opel Frontera UE. Manual - part 965

6E2–246

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

intake manifold, leaks at the throttle body, faulty or

incorrectly installed PCV valve, leaks at the intake

manifold, etc.

D

Throttle body – Check for sticking throttle plate. Also

inspect the IAC passage for deposits or objects which

keep the IAC pintle from fully extending.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

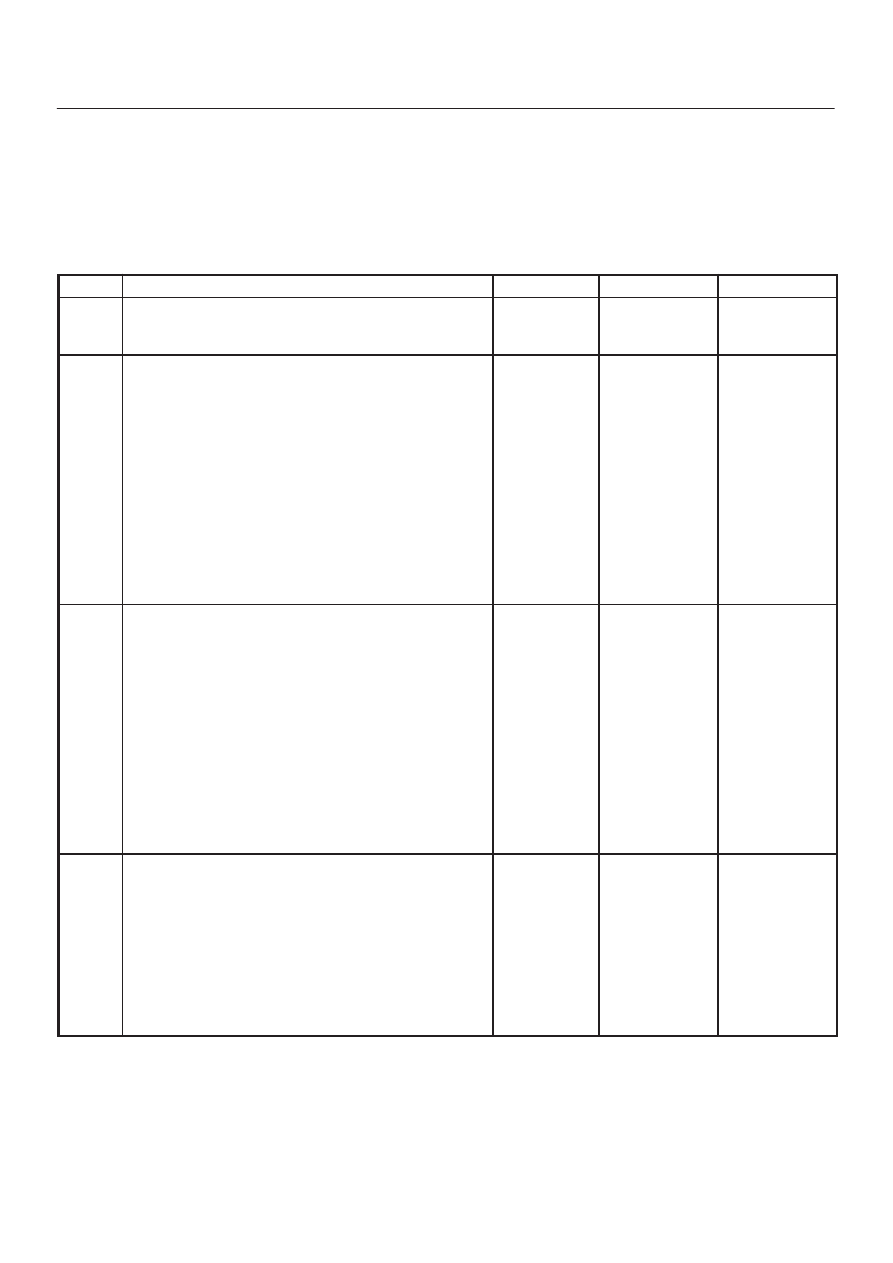

DTC P1509 –IAC System High RPM

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Start the engine.

2. Turn all accessories “OFF” (A/C, rear defroster,

etc.).

3. Using a Tech 2, command RPM up to 1500, down to

500, and then up to 1500 while monitoring “Engine

Speed” on the Tech 2.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does the “Engine Speed” remain within the specified

value of “Desired Idle” for each RPM command?

±

50 RPM

No trouble

found. Go to

Diagnostic

Aids

Go to

Step 3

3

1. Disconnect the IAC.

2. Install IAC Noid Light 5–8840–2312–0 or

equivalent.

3. With the engine running, command RPM up to

1500, down to 500, and then up to 1500 while

observing the noid light.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does each noid light cycle red and green (never

“OFF”)?

—

Go to

Step 5

Go to

Step 4

4

1. Check the following circuits for an open, short to

voltage, short ground, or poor connections at the

PCM:

D

IAC “A” Low.

D

IAC “A” High.

D

IAC “B” Low.

D

IAC “B” High.

2. If a problem its found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 8