Opel Frontera UE. Manual - part 925

6E2–86

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor (KS) System Check

(Engine Knock, Poor Performance, or Poor Economy)

D06RW035

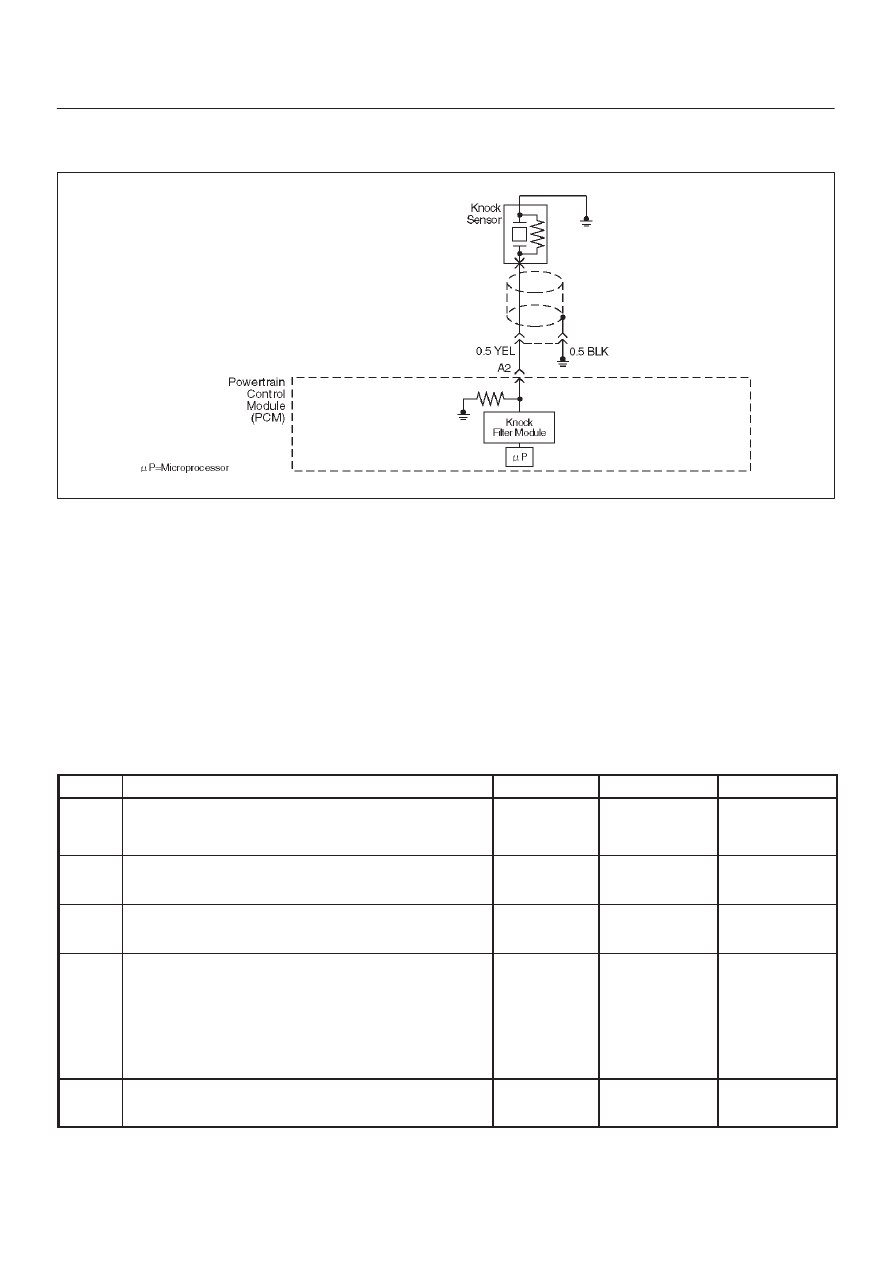

Circuit Description

The knock sensor (KS) sends an AC voltage signal to the

powertrain control module (PCM). As the KS detects

engine knock, the signal to the PCM changes in amplitude

and frequency. The PCM retards timing if the engine

speed is over 900 RPM.

Diagnostic Aids

If the KS system checks OK, but detonation is the

complaint, refer to

Diagnosis, Detonation/Spark Knock.

Test Description

The numbers below refer to the step numbers on the

Diagnostic Chart.

9. The change in signal speed depends on how hard

the tapping is done. Normally there is about 1.5 to

10 mV at PCM pin A2 with the engine off. Loud

tapping should be able to make the reading jump to

20-25 mV AC.

Knock Sensor (KS) System Check

(Engine Knock, Poor Performance, or Poor Economy)

Step

Action

Value(s)

Yes

No

1

Is DTC P0325 or P0327 set?

—

Go to

DTC

P0325 or

DTC P0327

Go to

Step 2

2

Run the engine at 1500 RPM.

Is there an internal engine knock?

—

Go to

Step 3

Go to

Step 4

3

Repair the mechanical problem.

Is the action complete?

—

Verify repair

—

4

1. Install the Tech 2.

2. Turn the ignition “ON.”

3. On the Tech 2 select F0: Data List.

4. Cycle through the list until “Knock Noise Channel” is

displayed.

Is knock retard at the specified value?

more than

0.1V

Go to

Step 5

Go to

Step 6

5

Replace the PCM.

Is the action complete?

—

Verify repair

—