Opel Frontera UE. Manual - part 919

6E2–62

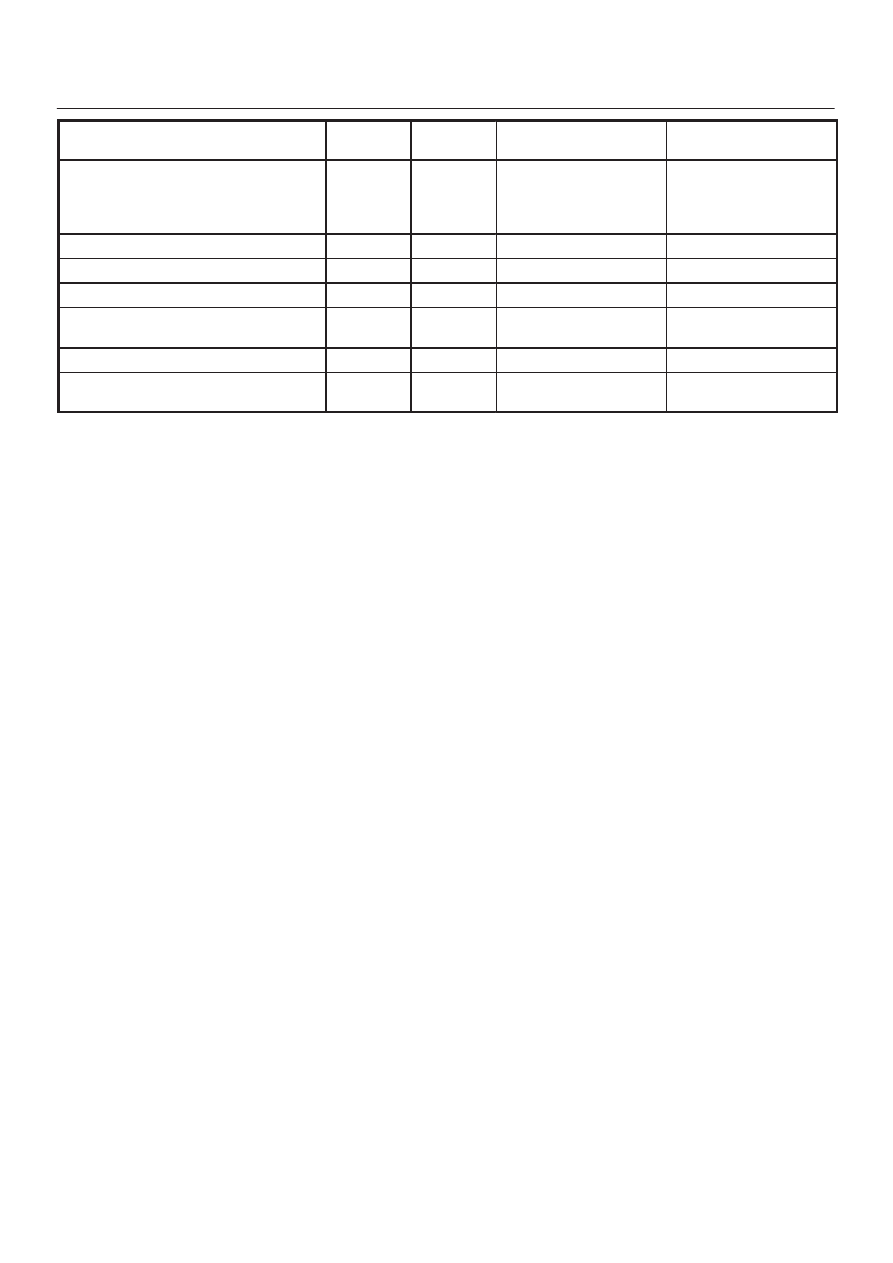

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Tech 2 Parameter

Typical Data Values

(2500 RPM)

Typical Data Values

(IDLE)

Units

Displayed

Data List

Fuel system Status

Engine

Closed

Loop

/Open

Loop

Closed Loop

Closed Loop

Power Enrichment

Engine

Yes/No

No

No

Engine Load

Engine

%

2.0 – 5.5

8.0 – 16.0

Time From Start

Engine

_:_:_

_:_:_

_:_:_

Deceleration Fuel Cutoff

Engine

Inactive/A

ctive

Inactive

Inactive

Malfunction Indicator Lamp

Engine

On/Off

Off

Off

VIM solenoid (Variable Intake

Manifold)

Engine

On/Off

On

On