Opel Frontera UE. Manual - part 896

6D2–2

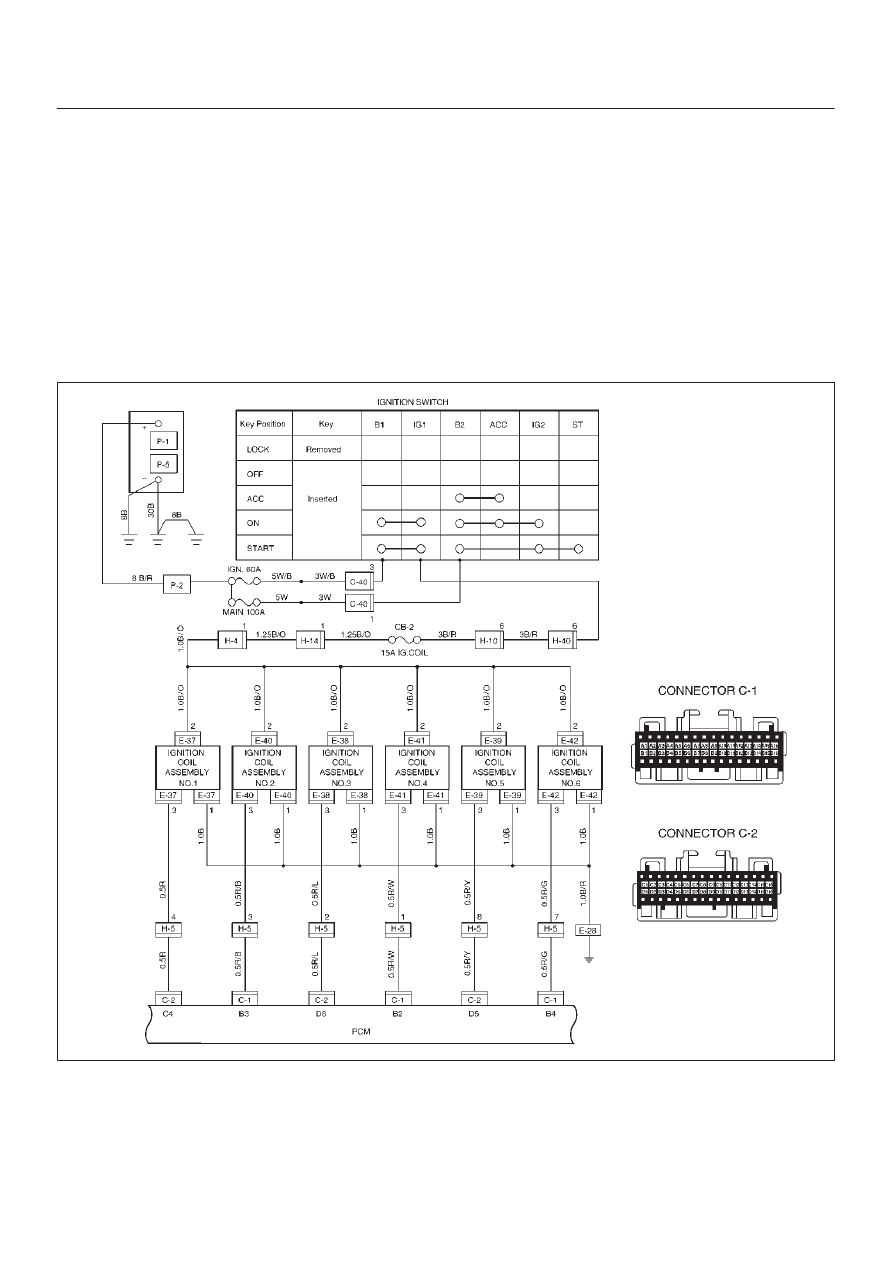

IGNITION SYSTEM (6VD1 3.2L)

General Description

Ignition is done by the electronic ignition (El) that directly

fires the spark plugs from ignition coils through spark plug

wires without using a distributor. A pair of ignition coils for

the cylinders having different phases by 360

°

(No.1 and

No.4,No.2 and No.5,No.3 and No.6) are fired

simultaneously.

Since the cylinder on exhaust stroke requires less energy

to fire its ignition plug, energy from the ignition coils can be

utilized to fire the mating cylinder on compression stroke.

After additional 360

°

rotation, respective cylinder strokes

are reversed.

The EI consists of six ignition coils,ignition control

module, crank angle sensor, powertrain control module

(PCM) and other components.

The ignition coils are connected with the PCM by means

of a 32 pin connector.

The ignition control module turns on/off the primary circuit

of ignition coils, and also it controls the ignition timing at

the engine speed below 538 rpm.

A notch in the timing disc on the crankshaft activates the

crank angle sensor which then sends information such as

firing order and starting timing of each ignition coil to the

PCM.

Further, the El employs ignition control (IC) to control

similar to a distributor system.

By receiving signals such as crank position,engine

speed, water temperature and Manifold Absolute

Pressure (MAP), the PCM controls the ignition timing.

D06RX096

Diagnosis

Refer to Section Drivability and Emissions for the

diagnosis to electronic ignition system (El system).