Opel Frontera UE. Manual - part 843

6E1–255

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

CUTS OUT, MISSES SYMPTOM

DEFINITION:

Steady pulsation or jerking that follows engine speed;

usually more pronounced as engine load increases.

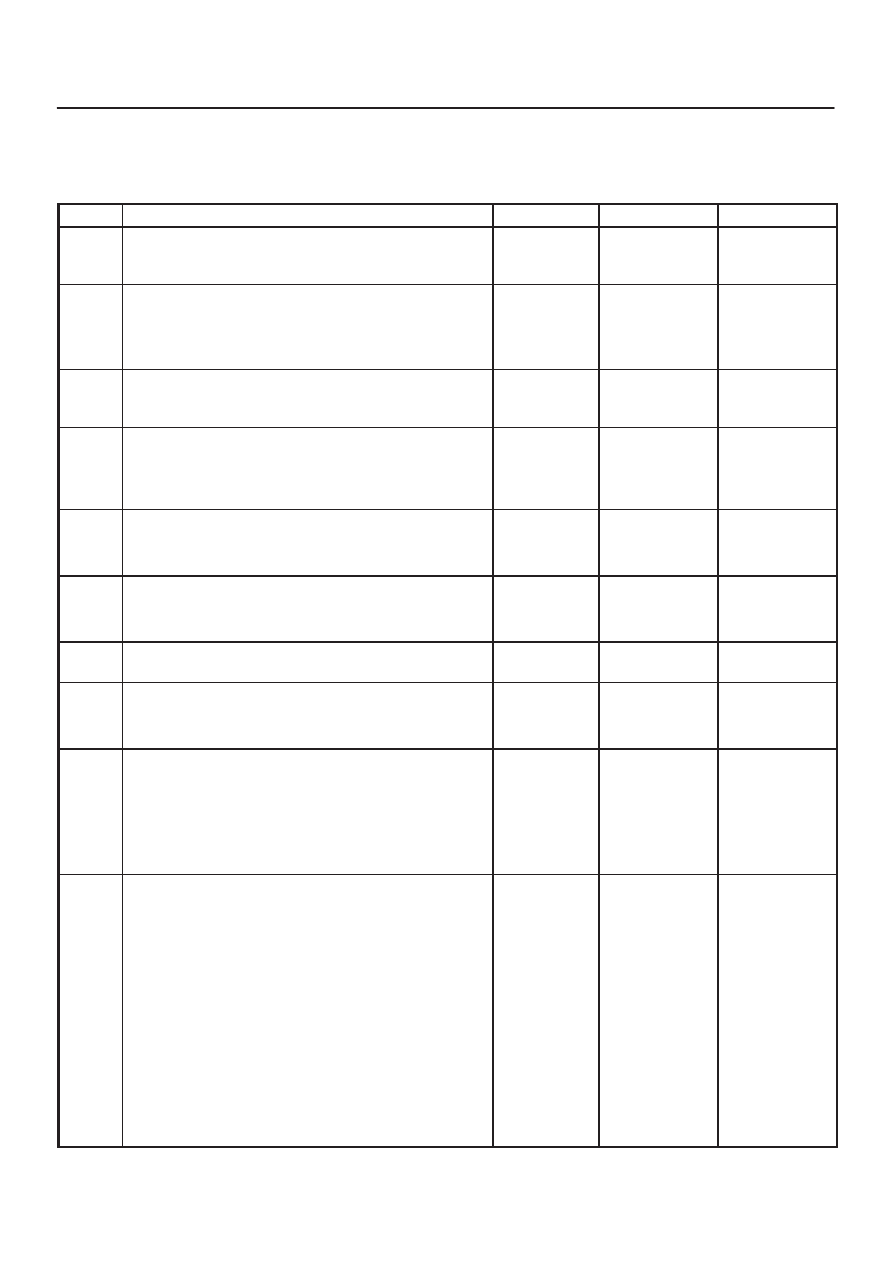

Step

Action

Value(s)

Yes

No

1

Was the On–Board Diagnostic (OBD) System Check

performed?

—

Go to Step 2

Go to OBD

System

Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to Step 3

3

Was a visual/physical check performed?

—

Go to Step 4

Go to Visual /

Physical

Check

4

Check the ECM grounds to verify that they are clean

and tight. Refer to the ECM wiring diagrams in

Electrical Diagnosis.

Was a problem found?

—

Verify repair

Go to Step 5

5

Monitor ”Long Term Fuel Trim” on the Tech 2.

Is the ”Long Term Fuel Trim” in the negative range (rich

condition)?

—

Go to Step 6

Go to Step 7

6

Check items that can cause the engine to run rich.

Refer to ”Diagnostic Aids” in DTC P0172.

Was a problem found?

—

Verify repair

Go to Step 9

7

Is the long term fuel trim significantly in the positive

range (lean condition)?

—

Go to Step 8

Go to Step 9

8

Check items that can cause the engine to run lean.

Refer to Diagnostic Aids in DTC P0171.

Was a problem found?

—

Verify repair

Go to Step 9

9

1. Check for incorrect idle speed. Ensure that the

following conditions are present:

D

Engine fully warm.

D

Accessories are OFF.

2. Using a Tech 2, monitor the IAC position.

Is the IAC position within the specified values?

Between 5

and 50

counts

Go to Step 11

Go to Step 10

10

1. Visually/physically inspect for the following

conditions:

D

Restricted air intake system. Check for a

restricted air filter element, or foreign objects

blocking the air intake system.

D

Check for objects blocking the IAC passage or

throttle bore, excessive deposits in the IAC

passage and on the IAC pintle, and excessive

deposits in the throttle bore and on the throttle

plate.

D

Check for a condition that causes a large

vacuum leak, such as an incorrectly installed

or faulty crankcase ventilation valve or brake

booster hose disconnected.

Was a problem found?

—

Verify repair

Go to Step 11