Opel Frontera UE. Manual - part 792

6E1–51

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

D

Damaged harness – Inspect the wiring harness for

damage; shorts to ground, shorts to battery voltage,

and open circuits. If the harness appears to be OK,

observe the A/C clutch while moving connnectors and

wiring harnesses related to the A/C. A sudden clutch

malfunction will indicate the source of the intermittent.

A/C Clutch Diagnosis

This chart should be used for diagnosing the electrical

portion of the A/C compressor clutch circuit. A Tech 2 will

be used in diagnosing the system. The Tech 2 has the

ability to read the A/C request input to the ECM. The Tech

2 can display when the ECM has commended the A/C

clutch ON. The Tech 2 should have the ability to override

the A/C request signal and energize the A/C compressor

relay.

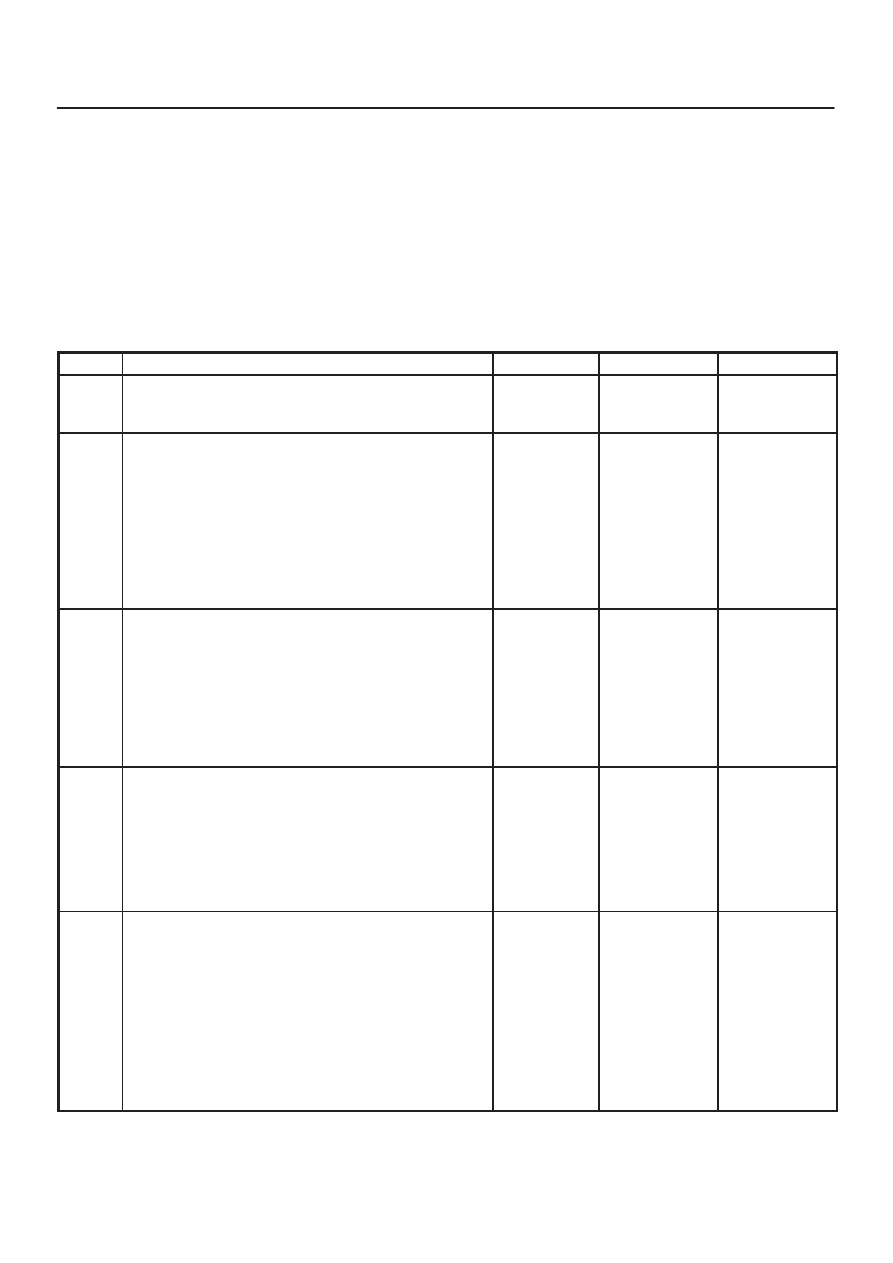

A/C Clutch Control Circuit Diagnosis

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

1. Ignition ON, engine OFF.

2. Review and record Tech 2 Failure Records data,

then clear the DTCs.

3. Operate the vehicle within the Failure Records

conditions as noted.

4. Using the Tech 2, monitor ”DTC” info for DTC

P1546.

Does the Tech 2 indicate DTC P1546 ”Ran and

Passed”?

—

Refer to

Diagnostic

Aids

Go to Step 3

3

1. Ignition OFF.

2. Remove the A/C Compressor Relay from the

Underhood Electrical Center.

3. Ignition ON, engine OFF.

4. Using a Digital Voltmeter (DVM), check for voltage

on the Fused pins of the A/C Compressor Clutch

Relat connector.

Does the DVM read the following value?

12 Volts

Go to Step 5

Go to Step 4

4

Check the suspect circuit(s) between the A/C

Compressor Clutch Relay connector and the Fuse for

the following conditions:

D

A short to ground

D

An open circuit

D

A short to voltage

Was the problem found?

—

Verify repair

—

5

1. Ignition OFF.

2. Disconnect the Engine Controlm Module (ECM)

connectors from the ECM.

3. Check the A/C Compressor Clutch Relay control

circuit between the ECM and Underhood Electrical

Center for the following conditions:

D

A short to ground

D

An open circuit

D

A short to voltage

Was the problem found?

—

Verify repair

Go to Step 6