Opel Frontera UE. Manual - part 750

ENGINE MECHANICAL (X22SE 2.2L)

6A–9

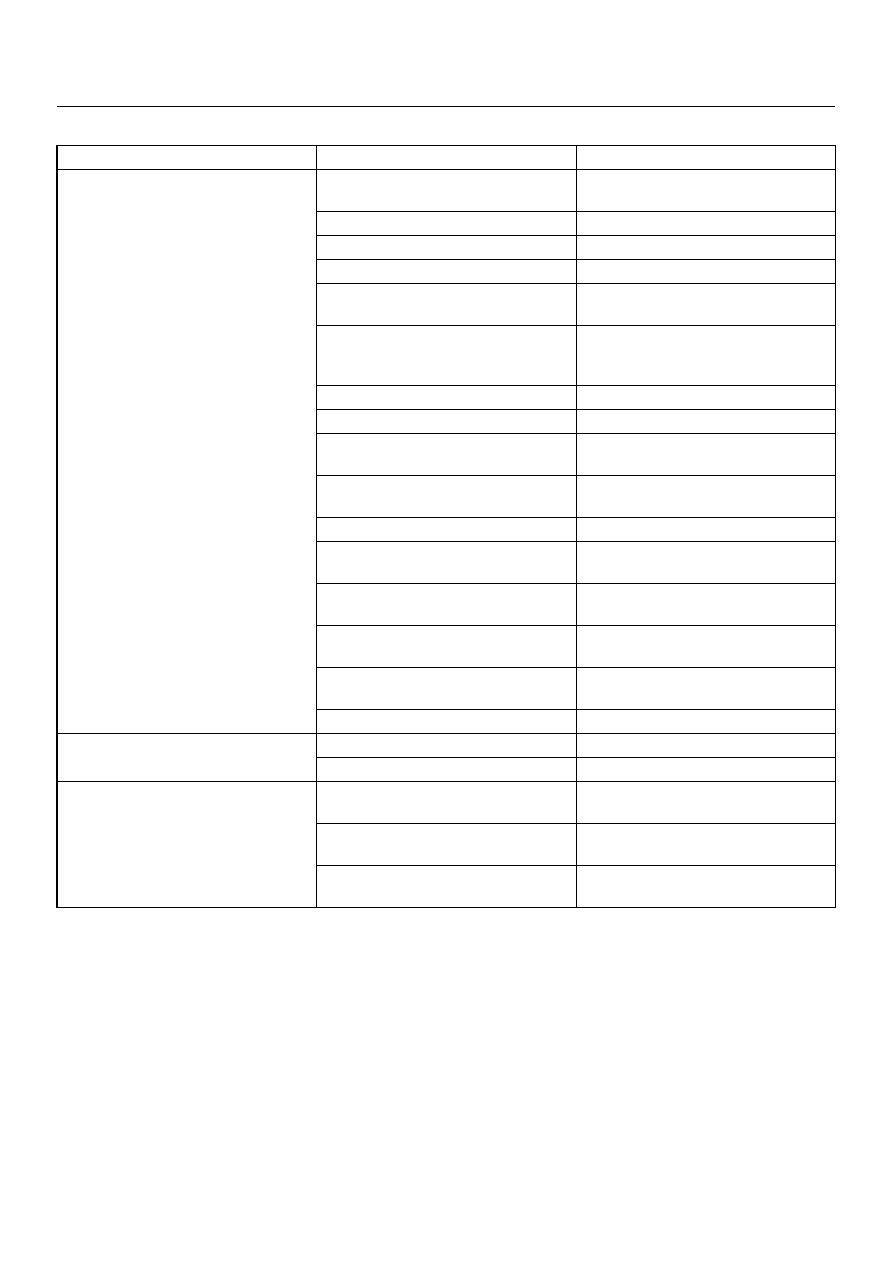

Engine Lacks Power

Condition

Possible cause

Correction

Trouble in fuel system

Fuel Pressure Control Valve not

working normally

Replace

Fuel injector clogged

Clean or replace

Fuel pipe clogged

Clean

Fuel filter clogged or fouled

Replace

Fuel pump drive circuit not working

normally

Correct or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuit

Clean or replace

Water in fuel system

Clean

Inferior quality fuel in fuel system

Use fuel of specified octane rating

Engine Control Module supplied

poor voltage

Correct circuit

Throttle Position Sensor cable

disconnected or broken

Correct or replace

Throttle Position Sensor defective

Replace

Manifold Absolute Pressure Sensor

not working normally

Replace

Intake Air Temperature Sensor not

working normally

Replace

Engine Coolant Temperature Sensor

circuit open or shorted

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Engine Control Module defective

Replace

Trouble in intake or exhaust system

Air Cleaner Filter clogged

Replace filter element

Air duct kinked or flattened

Correct or replace

Ignition failure

————

Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequate

Install spark plugs of adequate heat

range

Electronic Ignition System with

module

Replace