Opel Frontera UE. Manual - part 717

4D–40

TRANSFER CASE

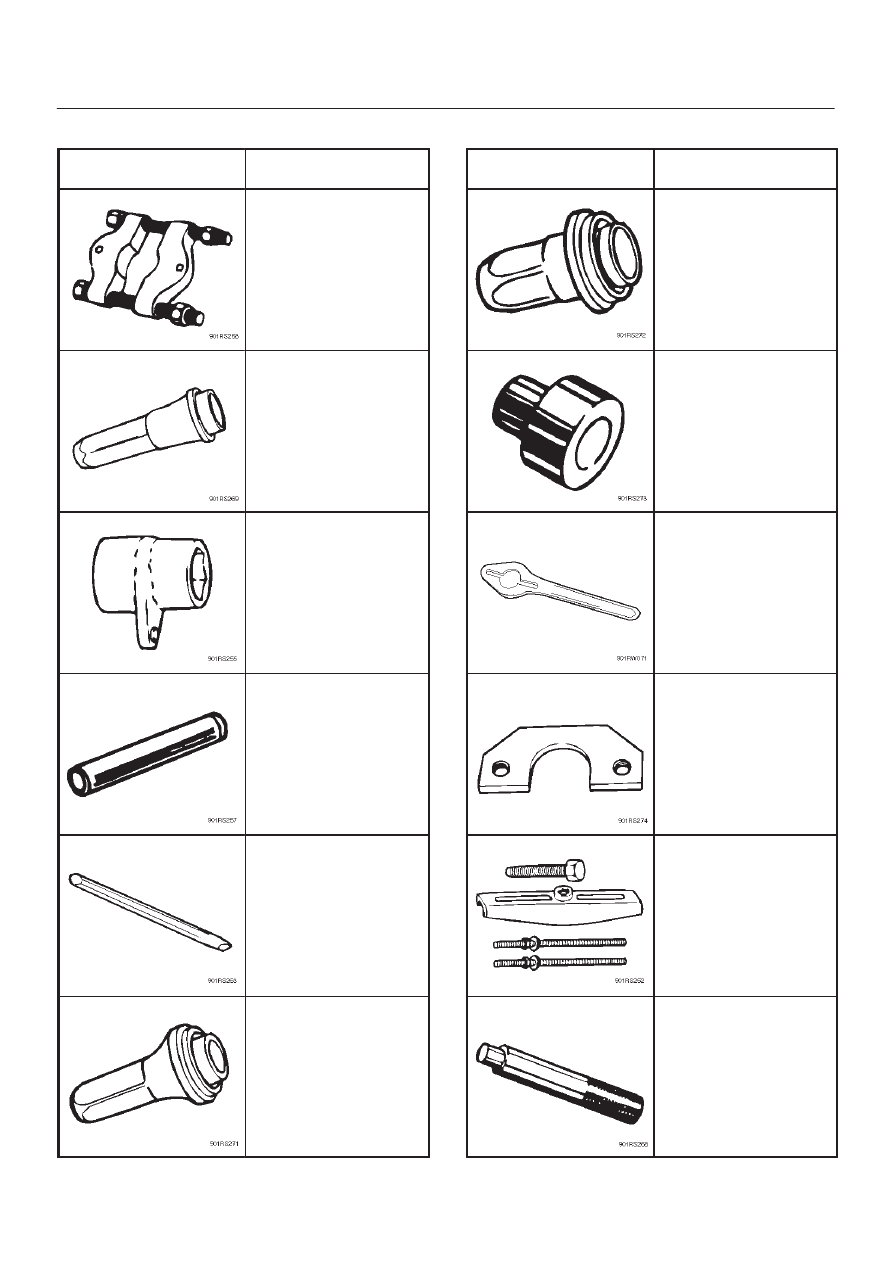

Special Tools

ILLUSTRATION

PART NO.

PART NAME

5–8840–0015–0

Bearing

remover/installer

5–8840–2279–0

Transfer case oil seal

installer

5–8840–2156–0

Mainshaft nut wrench

5–8840–2159–0

Rear output shaft and

bearing installer

5–8840–2293–0

Punch; end nut

5–8840–2281–0

Front output shaft oil

seal installer

ILLUSTRATION

PART NO.

PART NAME

5–8840–2292–0

Rear oil seal installer

5–8840–2192–1

Bearing installer adapter

5–8840–0133–0

Flange holder

5–8840–2155–0

Mainshaft end bearing

remover

5–8840–2027–0

Puller

5–8840–0007–0

Driver handle