Opel Frontera UE. Manual - part 627

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

1A–65

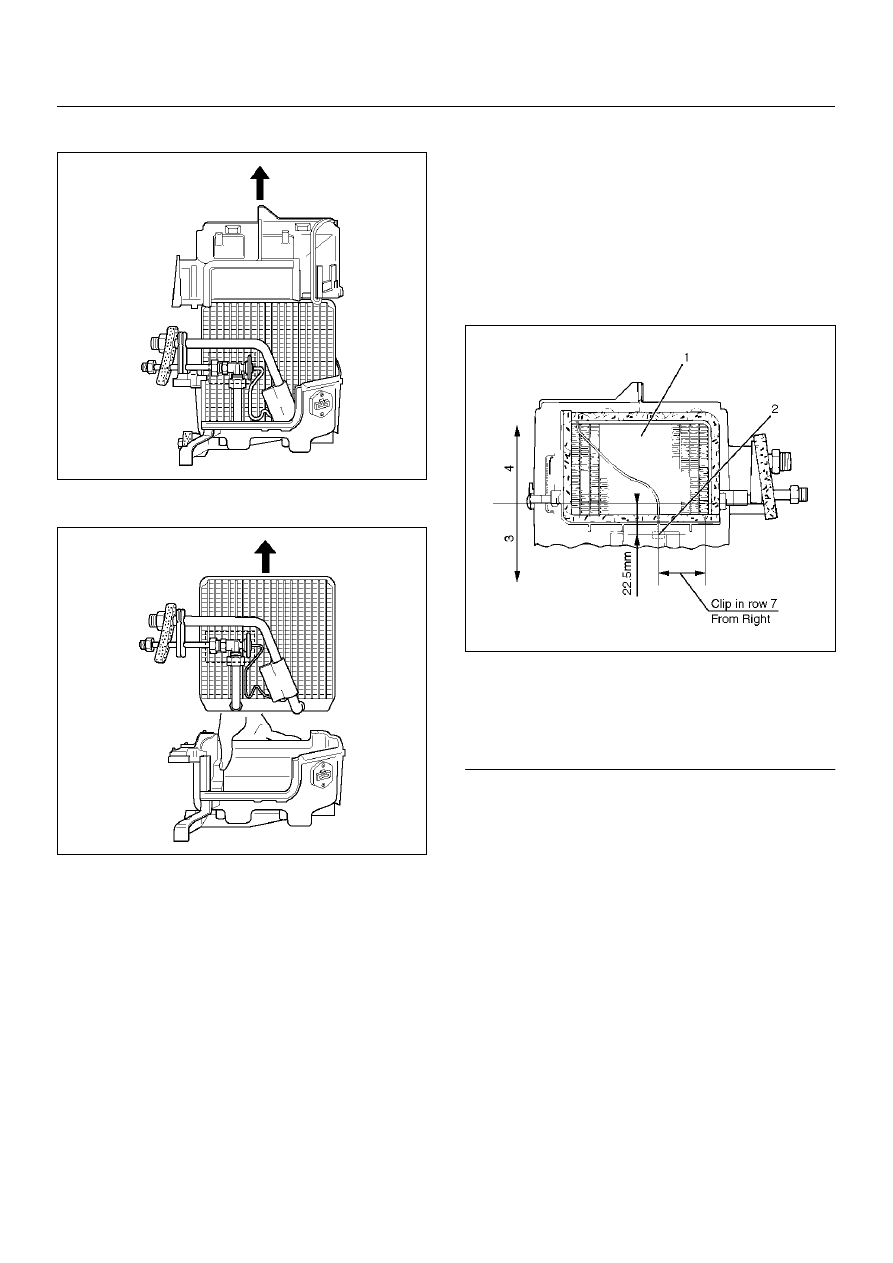

• Lift to remove the upper case.

874RY00027

8. Remove evaporator core.

874RY00028

9. Remove expansion valve.

• Tear off the insulator carefully.

• Remove the sensor fixing clip.

• Use a back-up wrench when disconnecting all

refrigerant pipes.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

1. The sensor is installed on the core with the clip.

2. The sensor must not interfere with the evaporator

core.

3. When installing the new evaporator core, install the

thermo sensor to the evaporator core specified

position with the clip in the illustration.

874RX014

EndOFCallout

4. O-rings cannot be reused. Always replace with new

ones.

5. Be sure to apply new compressor oil to the O-rings

when connecting lines.

6. Be sure to install the sensor and the insulator on the

place where they were before.

7. To install a new evaporator core, add 50cc (1.7 fl.

oz.) of new compressor oil to the new core.

8. Tighten the refrigerant lines to the specified torque.

Refer to Main Data and Specifications for Torque

Specifications in this section.

9. Apply an adhesive to the parting face of the lining

when assembling the evaporator assembly.

Legend

(1) Evaporator Core

(2) Thermo Sensor

(3) Lower Case

(4) Upper Case