Opel Frontera UE. Manual - part 622

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

1A–45

Magnetic Clutch Does Not Run (Cont’s)

CAUTION: There are condition whitch air

conditioner system dose not operate except trouble

as follows.

1. The throttle is greater than 90%.

2. The ignition voltage is below 10.5 volts.

3. The engine speed is greater than 4500 RPM for 5

seconds or 5400 RPM.

4. The engine coolant temperature (ECT) is greater

than 125

°

C (257

°

F).

5. The intake air temperature (IAT) is less than 5

°

C

(41

°

F).

6. The power steering pressure switch signals a high

pressure condition.

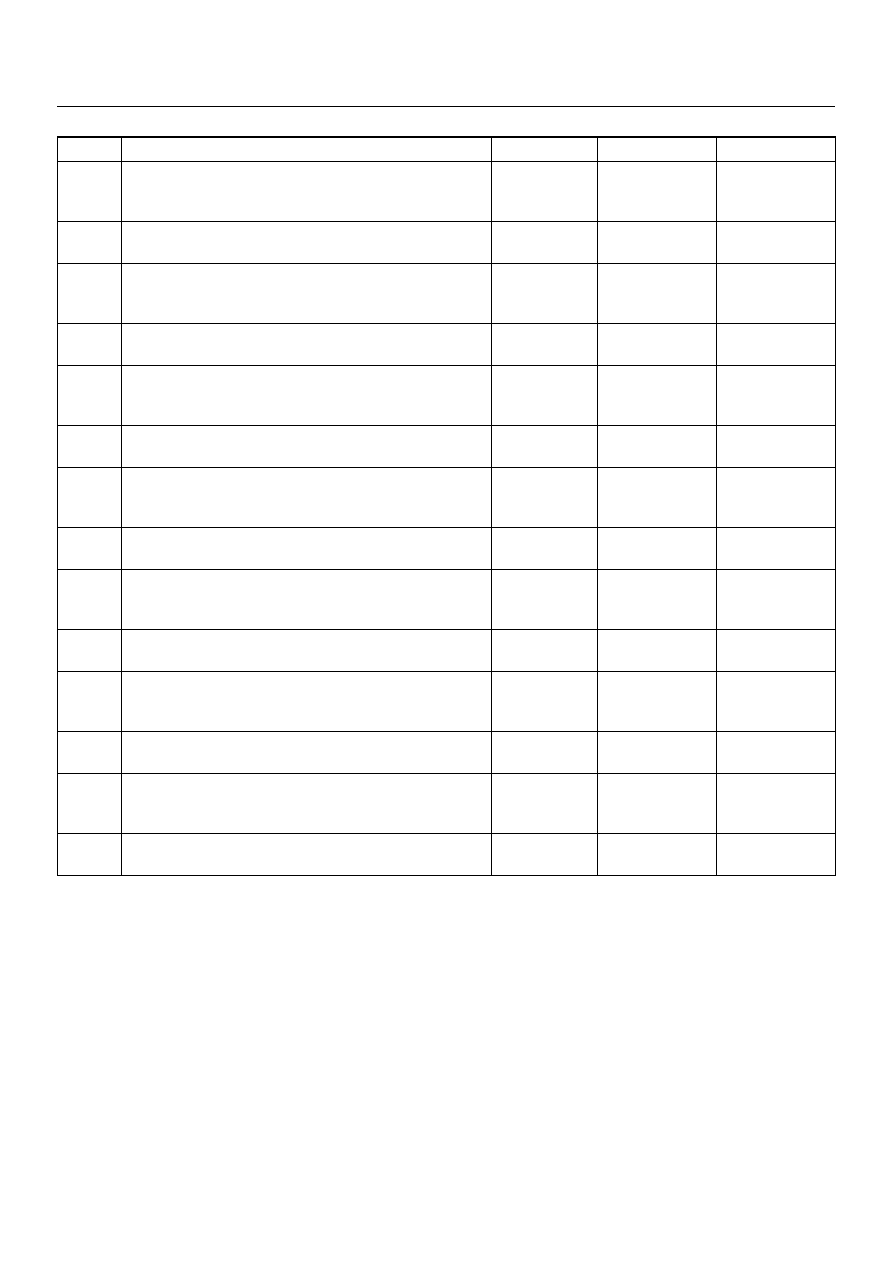

Step

Action

Value(s)

Yes

No

16

Repair an open circuit between terminal No.B4-3 and

No.I24-1.

Is the action complete?

—

Go to Step 15

—

17

Is there continuity between harness side connector

terminal No.I23-6 and No.B-2?

—

Go to Step 19

Go to Step 18

18

Repair an open circuit between terminal No.I23-6 and

No.B4-2.

Is the action complete?

—

Go to Step 17

—

19

Is there continuity between harness side connector

terminal No.I23-1 and ground (No.B-8)?

—

Go to Step 21

Go to Step 20

20

Repair an open circuit between terminal No.I23-1 and

No.B-8.

Is the action complete?

—

Go to Step 19

—

21

Is the battery voltage applied between harness side

connector terminal No.C11-1 and ground?

—

Go to Step 23

Go to Step 22

22

Repair an open circuit between terminal No.C11-1

and No.F-5 fuse.

Is the action complete?

—

Go to Step 21

—

23

Is the battery voltage applied between harness side

connector terminal No.X5-2 and ground?

—

Go to Step 25

Go to Step 24

24

Repair an open circuit between terminal No.X5-2 and

No.C11-2.

Is the action complete?

—

Go to Step 23

—

25

Is the battery voltage applied between harness side

connector terminal No.B4-1 and ground?

—

Go to Step 27

Go to Step 26

26

Repair an open circuit between terminal No.B4-1 and

No.X5-4.

Is the action complete?

—

Go to Step 25

—

27

Is there continuity between harness side connector

terminal No.X5-1 and No.C3-E15?

—

Go to Step 29

Go to Step 28

28

Repair an open circuit between terminal No.X5-1 and

No.C3-E15.

Is the action complete?

—

Verify repair

—

29

Replace the PCM.

Is the action complete?

—

Verify repair

—