Opel Frontera UE. Manual - part 270

6A–44

ENGINE MECHANICAL (6VD1 3.2L)

D

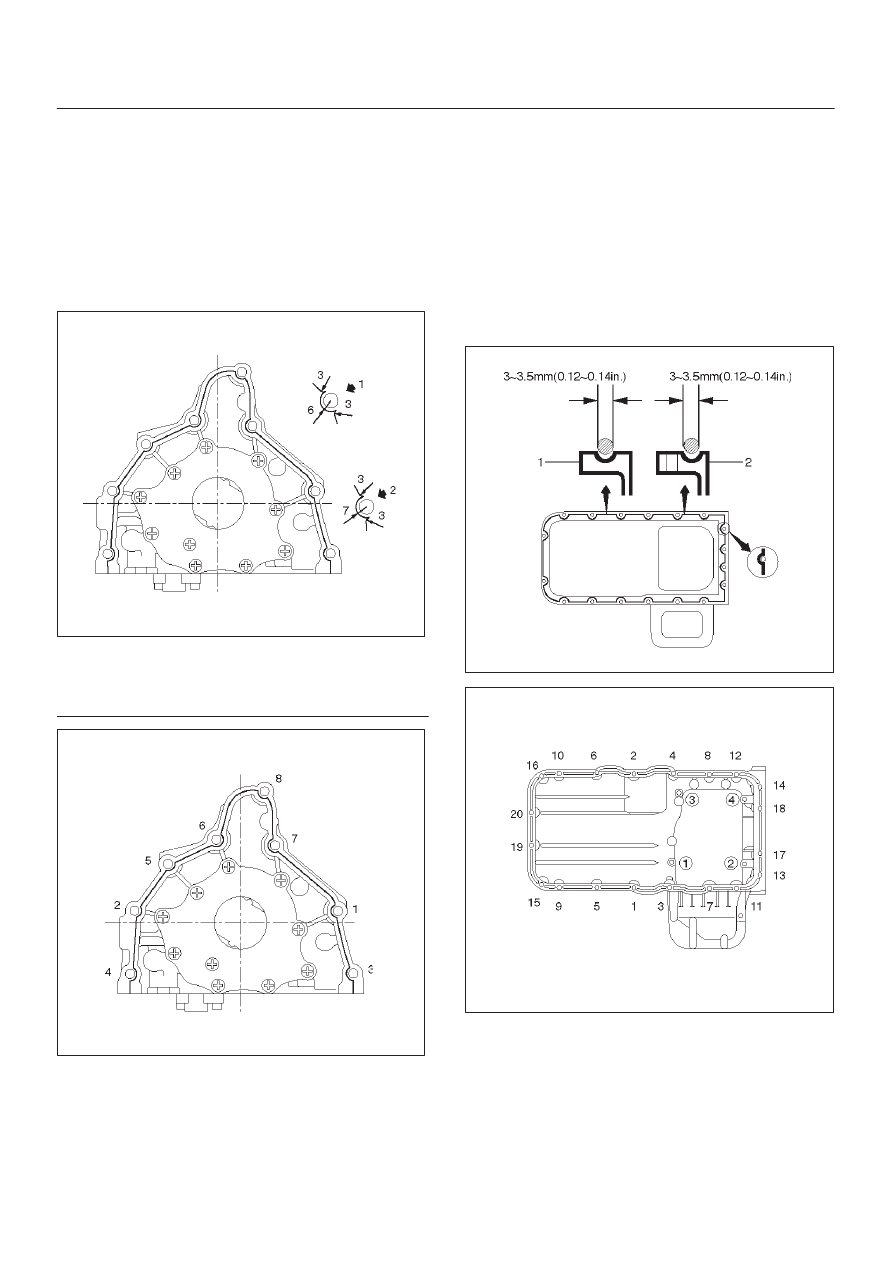

Apply sealant (TB1207B or equivalent) to the oil

pump mounting surface.

D

The oil pump assembly must be installed within 5

minutes after sealant application before the sealant

hardens.

D

Apply engine oil to oil seal lip.

D

Install oil pump in the cylinder block and tighten

fixing bolts to the specified torque.

Torque : 25 N·m (2.5 Kg·m/18 lb ft)

051RW002

Legend

(1) Around Bolt Holes

(2) Around Dowel Pin

051RW001

9. Install oil strainer with O-ring, tighten to the specified

torque.

Torque : 25 N·m (2.5 Kg·m/18 lb ft)

10. Install oil pipe with O-ring, tighten fixing bolts to the

specified torque.

Torque : 25 N·m (2.5 Kg·m/18 lb ft)

11. Install crankcase.

D

Remove oil on crankcase mounting surface and dry

the surface.

D

Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB1207C or equivalent) to the crankcase

mounting surface. The bead must be continuous.

D

The crankcase must be installed within 5 minutes

after sealant application before the sealant

hardens.

D

Tighten fixing bolts to the specified torque.

Torque : 10 N·m (1.0 Kg·m/89 lb in)

013RW010

013RW004

12. Install oil pan

D

Remove oil on oil pan mounting surface and dry the

surface.

D

Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB1207C or equivalent) to the oil pan

mounting surface. The bead must be continuous.

D

The oil pan must be installed within 5 minutes after

sealant application to prevent premature hardening

of sealant.