Opel Frontera UE. Manual - part 195

6E1–78

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

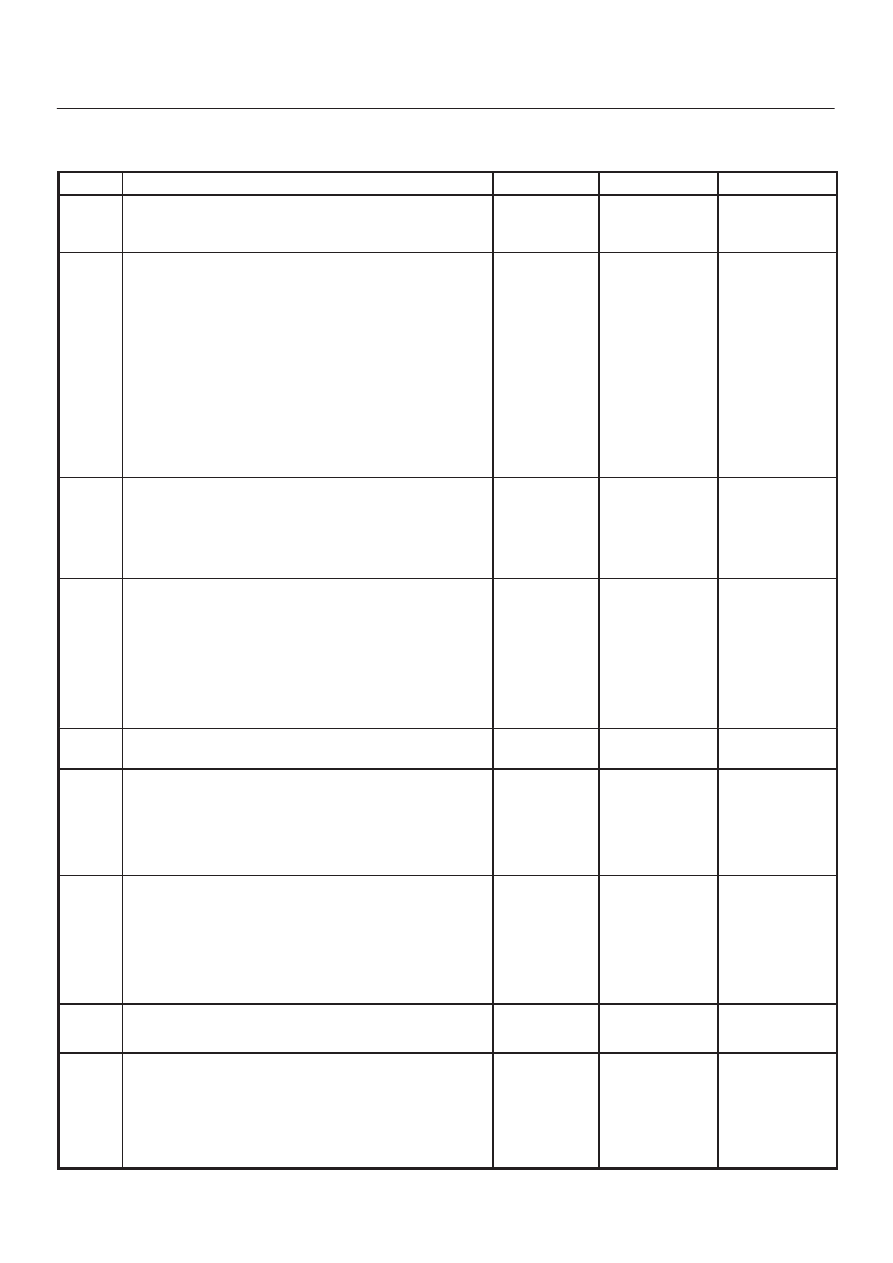

Fuel System Diagnosis

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

1. Turn the ignition OFF.

2. Turn the air conditioning system OFF.

3. Relieve fuel system pressure and install the fuel

pressure gauge.

4. Turn the ignition ON.

NOTE: The fuel pump will run for approximately 2

seconds. Use the Tech 2 to command the fuel pump

ON.

5. Observe the fuel pressure indicated by the fuel

pressure gauge with the fuel pump running.

Is the fuel pressure within the specified limits?

283–376 kPa

(41–55 psi)

Go to Step 3

Go to Step 17

3

NOTE: The fuel pressure will drop when the fuel pump

stops running, then it should stabilize and remain

constant.

Does the fuel pressure indicated by the fuel pressure

gauge remain constant?

—

Go to Step 4

Go to Step 12

4

1. When the vehicle is at normal operating

temperature, turn the ignition ON to build fuel

pressure and observe the measurement on the

gauge.

2. Start the engine and observe the fuel pressure

gauge.

Did the reading drop by the amount specified after the

engine was started?

21–105 kPa

(3–15 psi)

Go to Step 5

Go to Step 9

5

Is fuel pressure dropping off during acceleration,

cruise, or hard cornering?

—

Go to Step 6

Check for

improper fuel

6

Visually and physically inspect the following items for a

restriction:

D

The in–pipe fuel filter.

D

The fuel feed line.

Was a restrication found?

—

Verify repair

Go to Step 7

7

Remove the fuel tank and visually and physically

inspect the following items:

D

The fuel pump strainer for a restriction.

D

The fuel line for a leak.

D

Verify that the correct fuel pump is in the vehicle.

Was a problem found in any of these areas?

—

Verify repair

Go to Step 8

8

Replace the fuel pump.

Is the action complete?

—

Verify repair

—

9

1. Disconnect the vacuum hose from the fuel pressure

regulator.

2. With the engine idling, apply 12–14 inches of

vacuum to the fuel pressure regulator.

Does the fuel pressure indicated by the fuel pressure

gauge drop by the amount specified?

21–105 kPa

(3–15 psi)

Go to Step 10

Go to Step 11