Content .. 1623 1624 1625 1626 ..

Opel Frontera UE. Manual - part 1625

MANUAL TRANSMISSION

7B–49

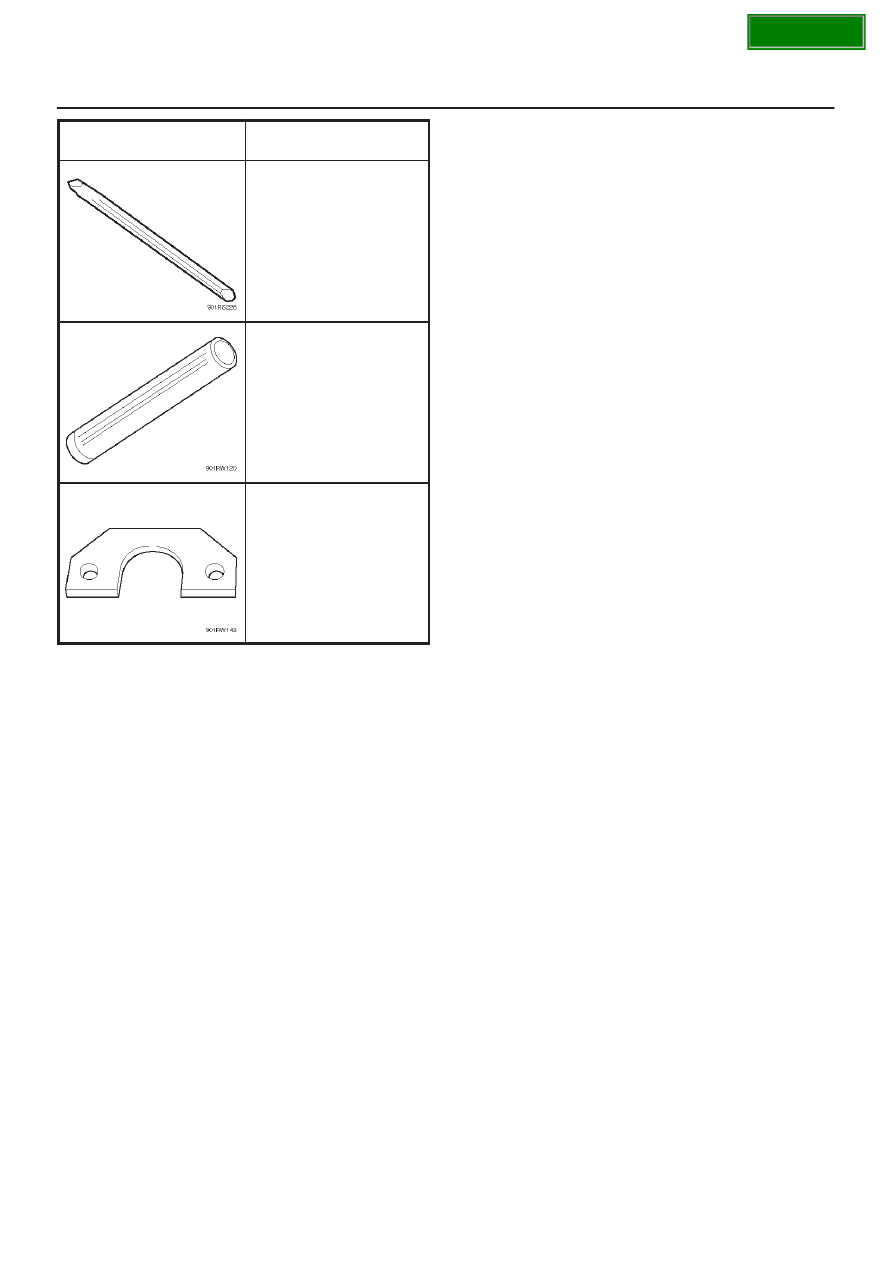

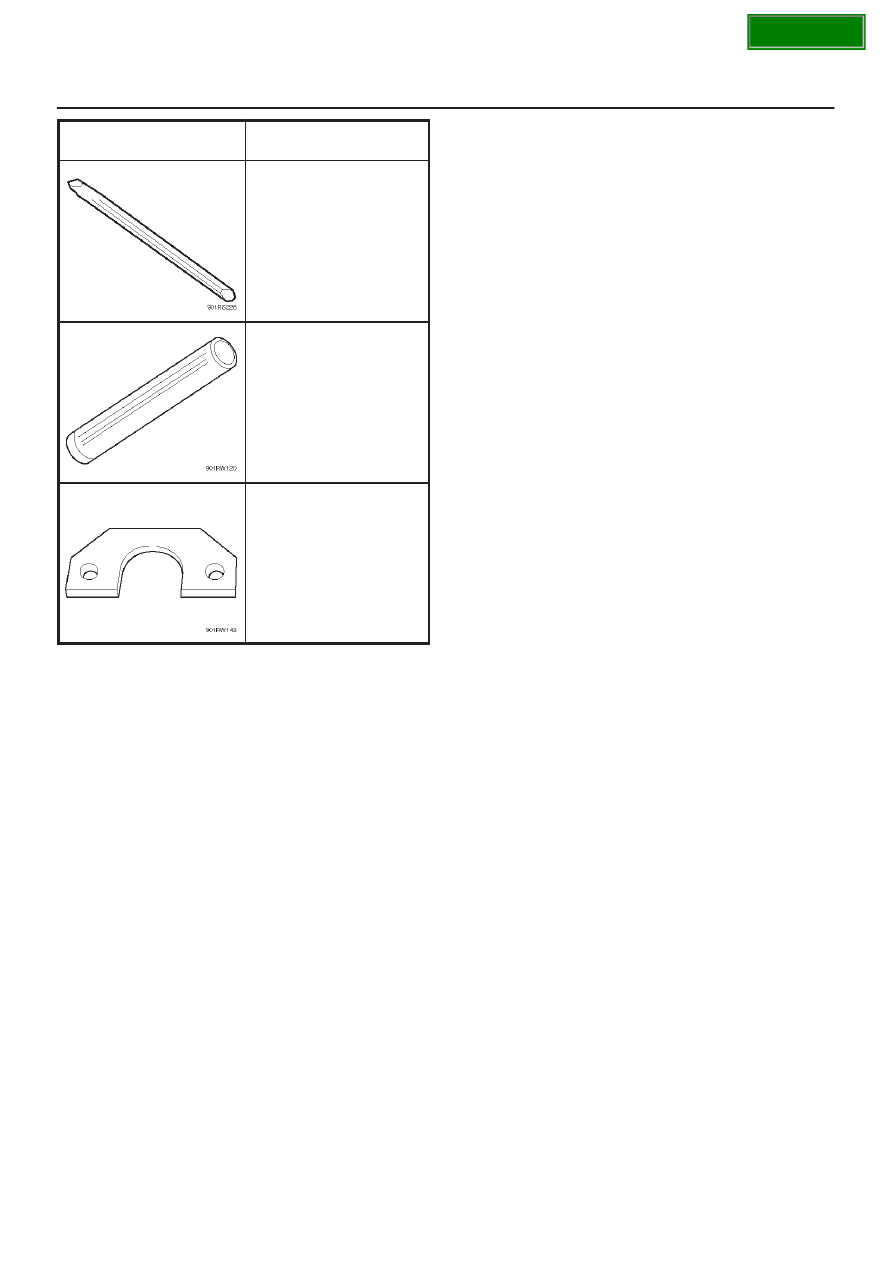

ILLUSTRATION

TOOL NO.

TOOL NAME

5–8840–2293–0

Punch; end nut

5–8840–2194–0

Counter shaft bearing

installer

5–8840–2155–0

Bearing remover

|

|

|

Content .. 1623 1624 1625 1626 ..

MANUAL TRANSMISSION 7B–49 ILLUSTRATION TOOL NO. TOOL NAME 5–8840–2293–0 Punch; end nut 5–8840–2194–0 Counter shaft bearing installer 5–8840–2155–0 Bearing remover |