Content .. 1509 1510 1511 1512 ..

Opel Frontera UE. Manual - part 1511

6E–259

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

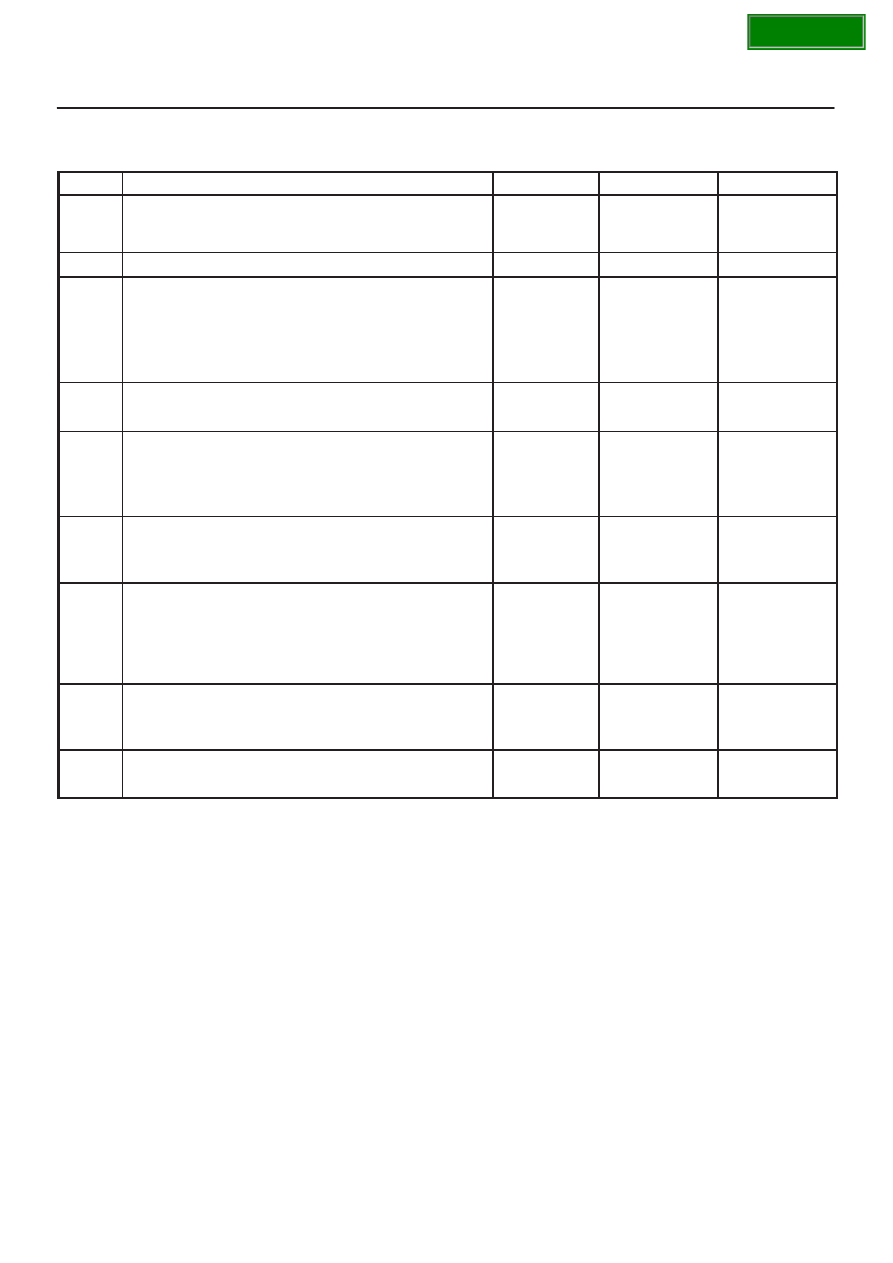

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

Does the speedometer work?

—

Go to

Step 10

Go to

Step 3

3

1. Disconnect the VSS connector.

2. Ignition “ON”.

3. Using a test light to battery +, probe the connector

ground wire.

Did the light illuminate?

—

Go to

Step 5

Go to

Step 4

4

Repair the sensor ground.

Is the action complete?

—

Verify repair

—

5

1. Ignition “ON”, sensor disconnected.

2. Using a DVM, measure at the VSS connector

between ground and voltage supply.

Was the measurement near the specified value?

Battery

voltage

Go to

Step 7

Go to

Step 6

6

Repair the open or short to ground which may have

blown the meter fuse.

Is the action complete?

—

Verify repair

—

7

1. Ignition “ON”, VSS disconnected.

2. Using a DVM, measure at the VSS connector

between ground and the wire from the

speedometer.

Was the measurement near the specified value?

7.5-8 V

Go to

Step 9

Go to

Step 8

8

Check for an open or short circuit between the

speedometer and the VSS.

Was an open or short circuit located?

—

Verify repair

Go to

Step 9

9

Replace the speedometer.

Is the action complete?

—

Verify repair

—