Content .. 1412 1413 1414 1415 ..

Opel Frontera UE. Manual - part 1414

6A–33

ENGINE MECHANICAL (6VD1 3.2L)

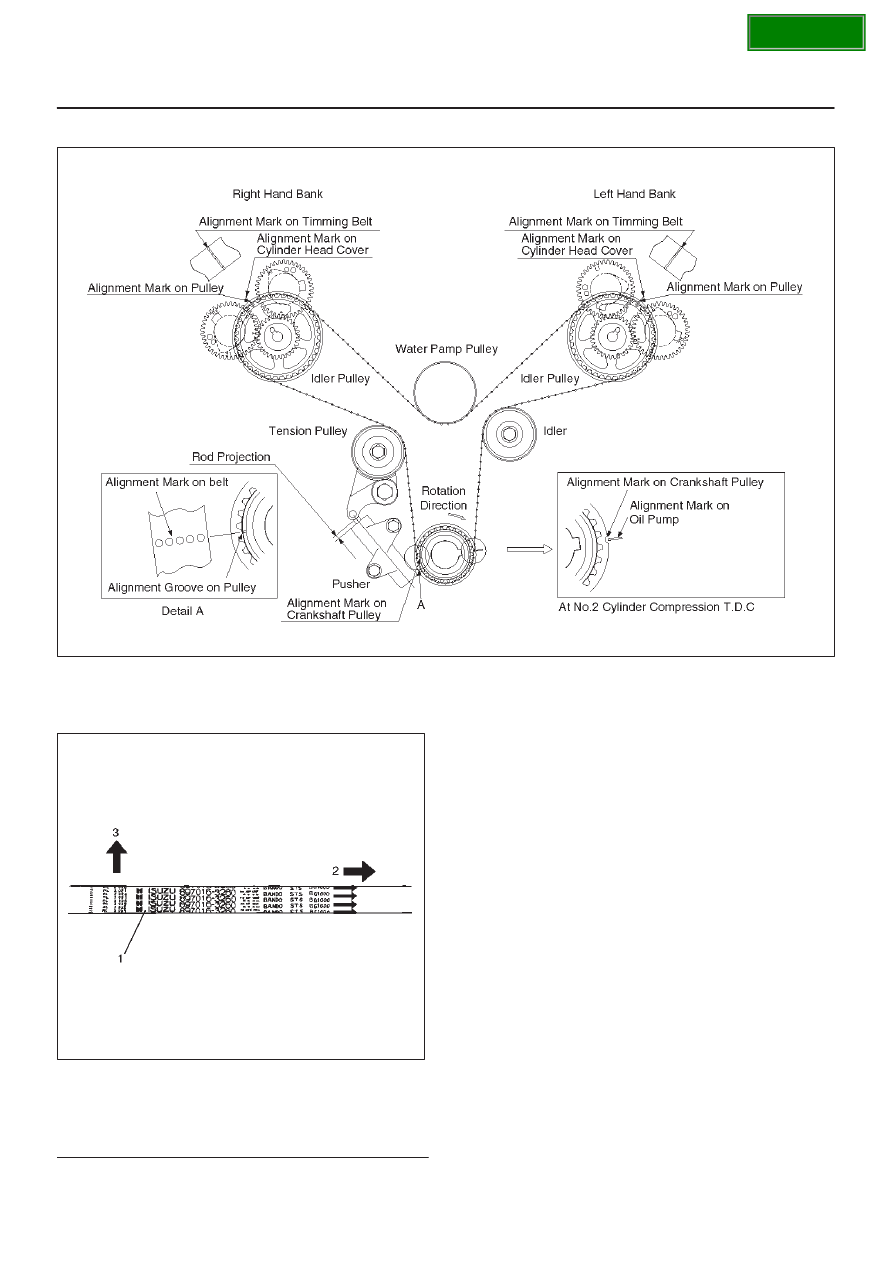

Installation

014R100015

NOTE: For correct belt installation, the letter on the belt

must be able to be read as viewed from the front of the

vehicle.

014RW006

Legend

(1) Timing Belt

(2) Engine Rotation Direction

(3) Cylinder Head Side